Photovoltaic module, photovoltaic adhesive film and preparation method thereof

A photovoltaic module and adhesive film technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems that the adhesive film is prone to slipping and affects the production speed and yield of photovoltaic modules, so as to increase friction and ensure The effect of seamless fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

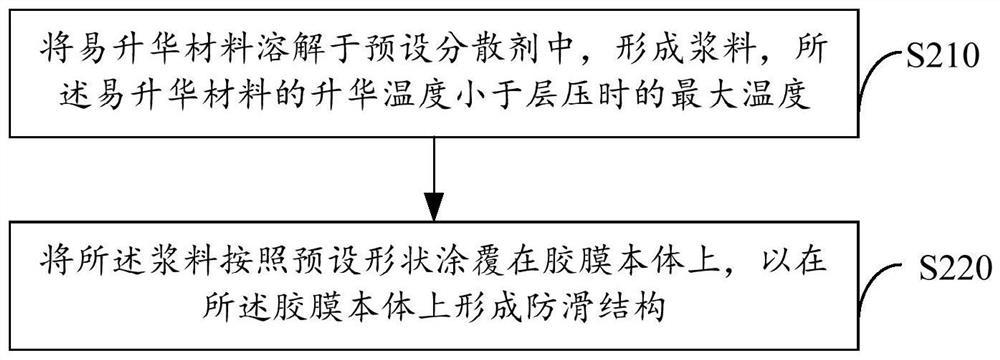

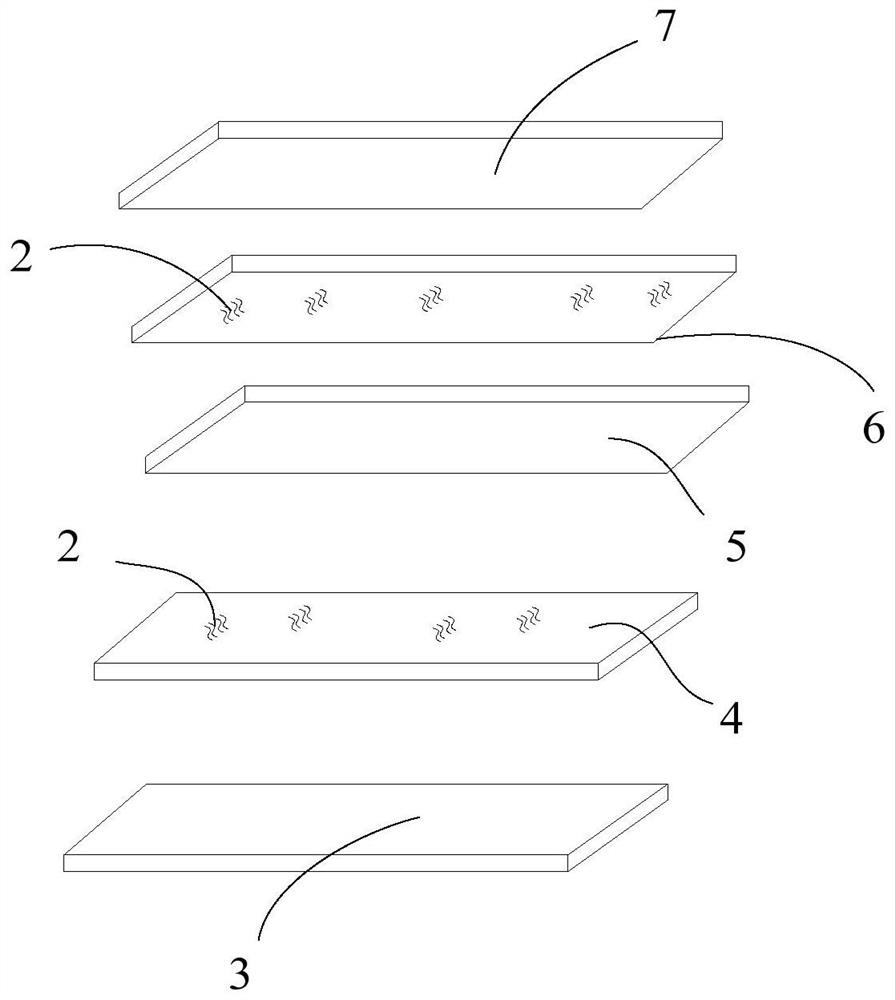

[0044] The present invention also provides a preparation method of the above-mentioned photovoltaic adhesive film, please refer to figure 2 , including the following steps:

[0045] Step S210: dissolving the easily sublimable material in a preset dispersant to form a slurry, the sublimation temperature of the easily sublimable material is lower than the maximum temperature during lamination;

[0046] Specifically, the easily sublimable material is one or more of naphthalene, aluminum trichloride or anthracene, by setting the surface of battery sheet 5 made of naphthalene, aluminum trichloride and silicon, conductive silver paste (Al, Ag), Substances such as tin-coated copper tape (Sn, Pb) are difficult to react, and after the lamination process, naphthalene or aluminum trichloride is sublimated and separated from the module system in a gaseous state, which can effectively avoid the impact of residual substances on the performance of photovoltaic modules. Correspondingly, the p...

Embodiment 1

[0056] (1) Preparation of anti-slip grain slurry:

[0057] Dissolve 10g of naphthalene (naphthalene will sublimate at room temperature at 25°C) in 20ml of polyvinylidene fluoride (PVDF) N-methylpyrrolidone solvent (NMP solvent), stir and mix well to form a slurry;

[0058] (2) Preparation of anti-slip photovoltaic adhesive film:

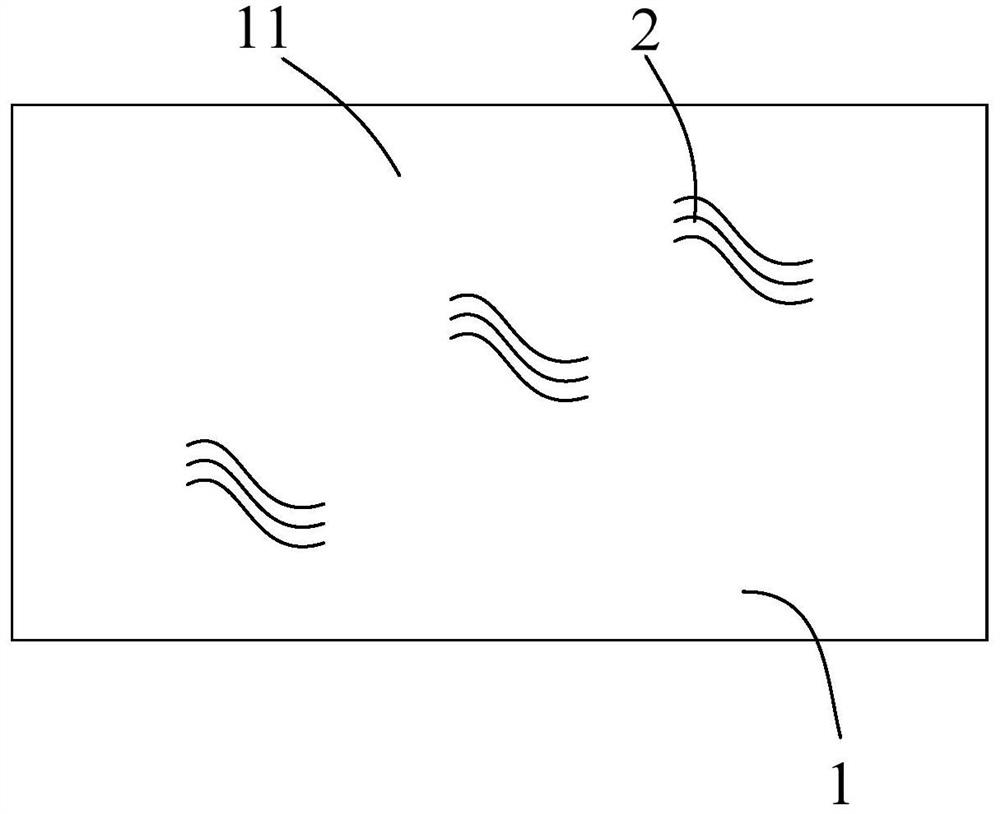

[0059] Paste a hollowed-out film according to a preset shape on the film body 1 (EVA), add the slurry to the hollowed-out part of the hollowed-out film, and remove the hollowed-out film after the slurry is cured, so that An anti-slip structure 2 is formed on the adhesive film body 1, wherein the preset shape is a wave shape.

Embodiment 2

[0061] (1) Preparation of anti-slip grain slurry:

[0062] Dissolve 10g of aluminum trichloride (sublimation temperature 178°C) in 20ml of polyvinylidene fluoride (PVDF) N-methylpyrrolidone solvent (NMP solvent), stir and mix well to form a slurry;

[0063] (2) Preparation of anti-slip photovoltaic adhesive film:

[0064] Paste a hollowed-out film according to a preset shape on the film body 1 (POE), in which a gap is formed at the hollowed-out position for two adjacent semiconductor sheets, and the slurry is added to the hollowed-out part of the hollowed-out film After the slurry is solidified, remove the hollowed-out film to form an anti-slip structure 2 on the film body 1, wherein the preset shape is wavy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com