Novel PCB base material structure and PCB lamination manufacturing method using same

A manufacturing method and base material technology, applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, printed circuit components, etc., can solve problems affecting the conduction of different layers of lines, so as to avoid the problem of unqualified quality, save labor costs, Facilitate the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

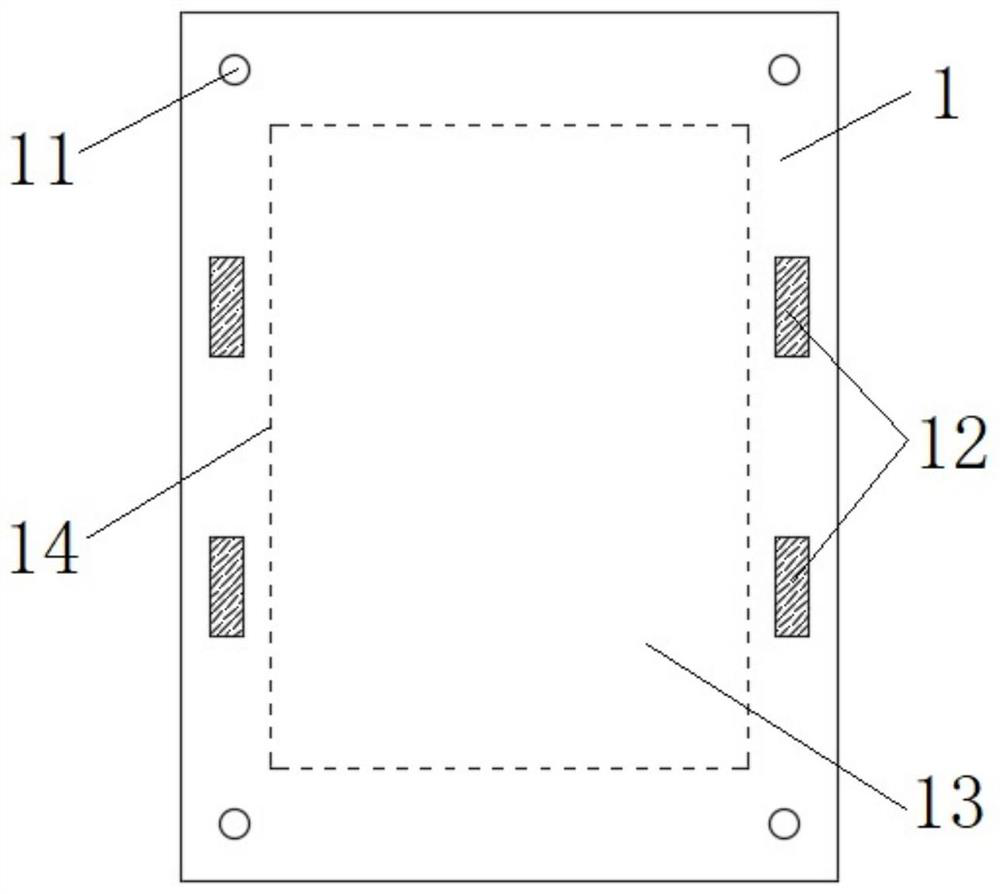

[0033] Such as figure 2 As shown, a novel PCB base material structure of the present invention includes a rectangular base material, and the base material has a circuit part 13 in the middle and several alignment holes 11 located outside the circuit part 13, and the base material 1 is in Fusion blocks 12 are also provided on the outer edge of the line portion 13 . The fusion block 12 is a structure that can be thermally fused, which can combine the edge of the base material 1 with the edge of the dielectric layer 2 to resist deformation during processing.

[0034] At least two fusion blocks 12 are provided on the edge of each long side of the substrate 1 . Because the middle part of the long side is easier to shrink, it is necessary to use multiple fusion blocks 12 to increase the fixed position to further ensure the quality of PCB products.

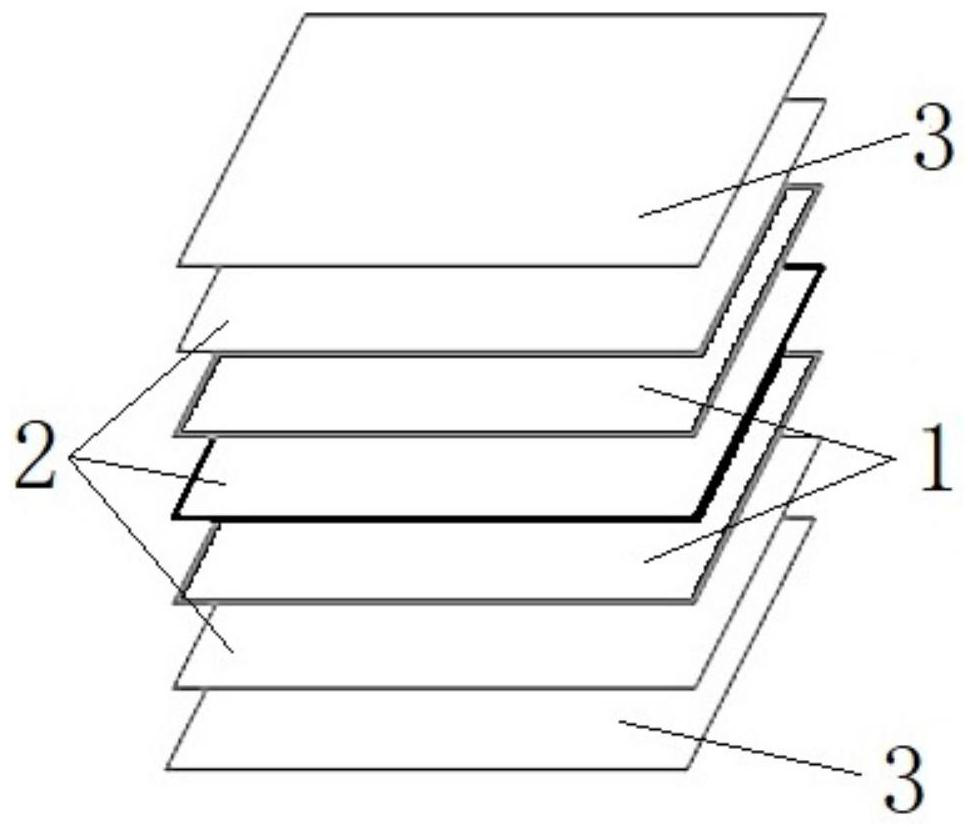

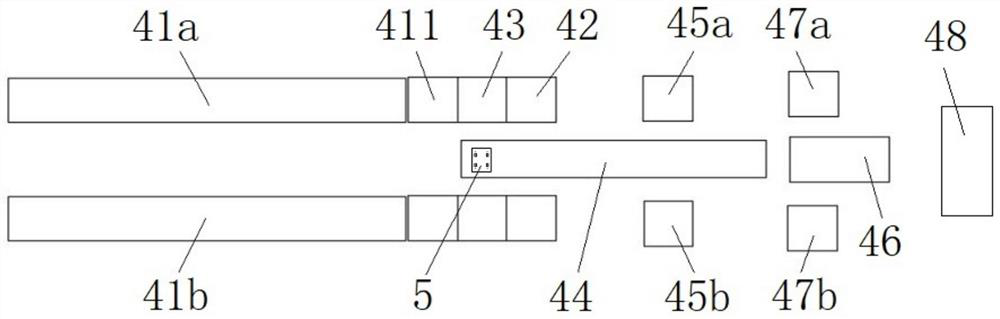

[0035] Such as Figure 1 to Figure 3 As shown, a novel PCB lamination manufacturing method, the steps include:

[0036] ①Pre-proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com