Frozen dough improver and application thereof

A technology for frozen dough and improver, applied in the field of frozen dough, can solve the problems of unsatisfactory health needs, complex ingredients, low nutritional value, etc., and achieve the effects of soft taste, smooth skin and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Put 5g of yeast, 100g of white sugar, 500g of high-precision flour, 5g of salt, 40g of eggs and 300g of water into the automatic dough making machine for mixing, then knead in the automatic dough making machine for 2 minutes at a slow speed, then 3 minutes at a fast speed ; Add 40g of butter, knead slowly for 2 minutes, and fast for 1 minute to form a dough. The dough is divided, shaped, and then placed in a -40°C freezer for 5 weeks to obtain frozen dough 1.

[0044](2) Put the frozen dough in step (1) into a constant temperature and humidity box and thaw it for 1 hour at a temperature of 37°C and a humidity of 90%, then divide and shape the dough, and place it at a temperature of 37°C Proof for 2 hours under the condition of humidity of 90%, and then put into an oven and bake for 30 minutes under the condition of upper heat of 220°C and lower heat of 180°C to obtain bread 1.

Embodiment 2

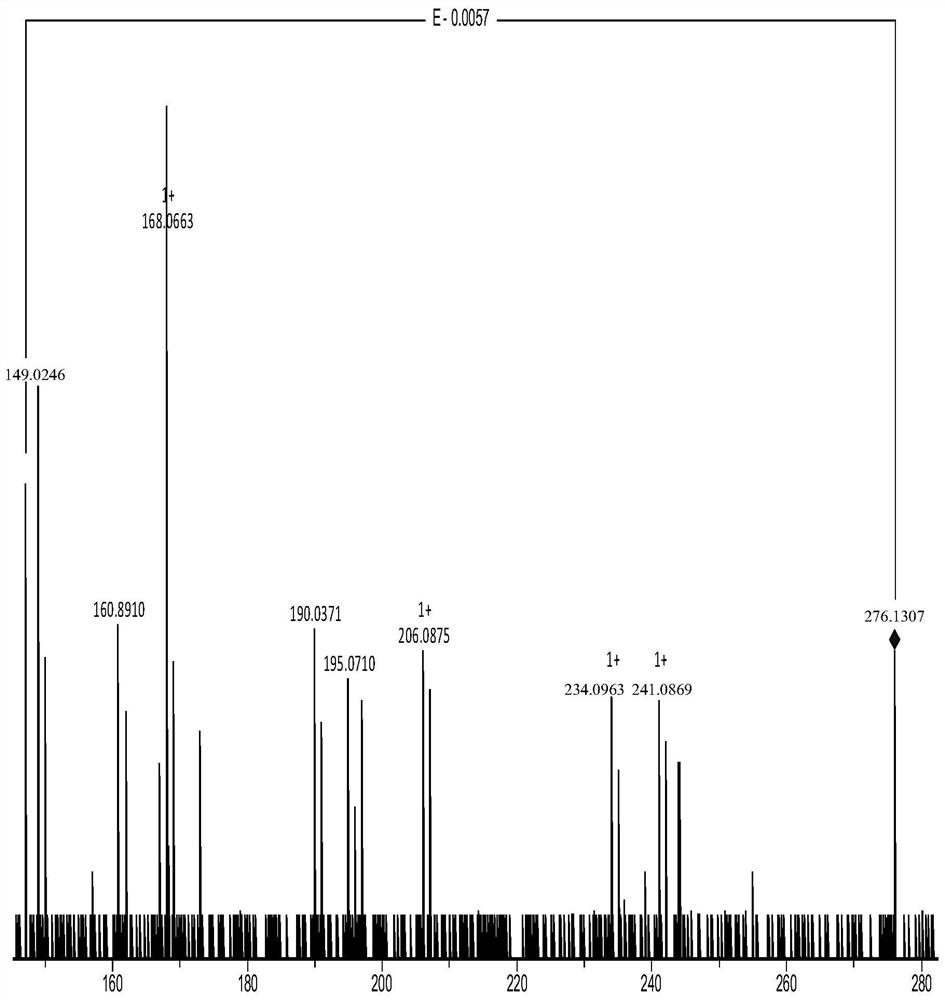

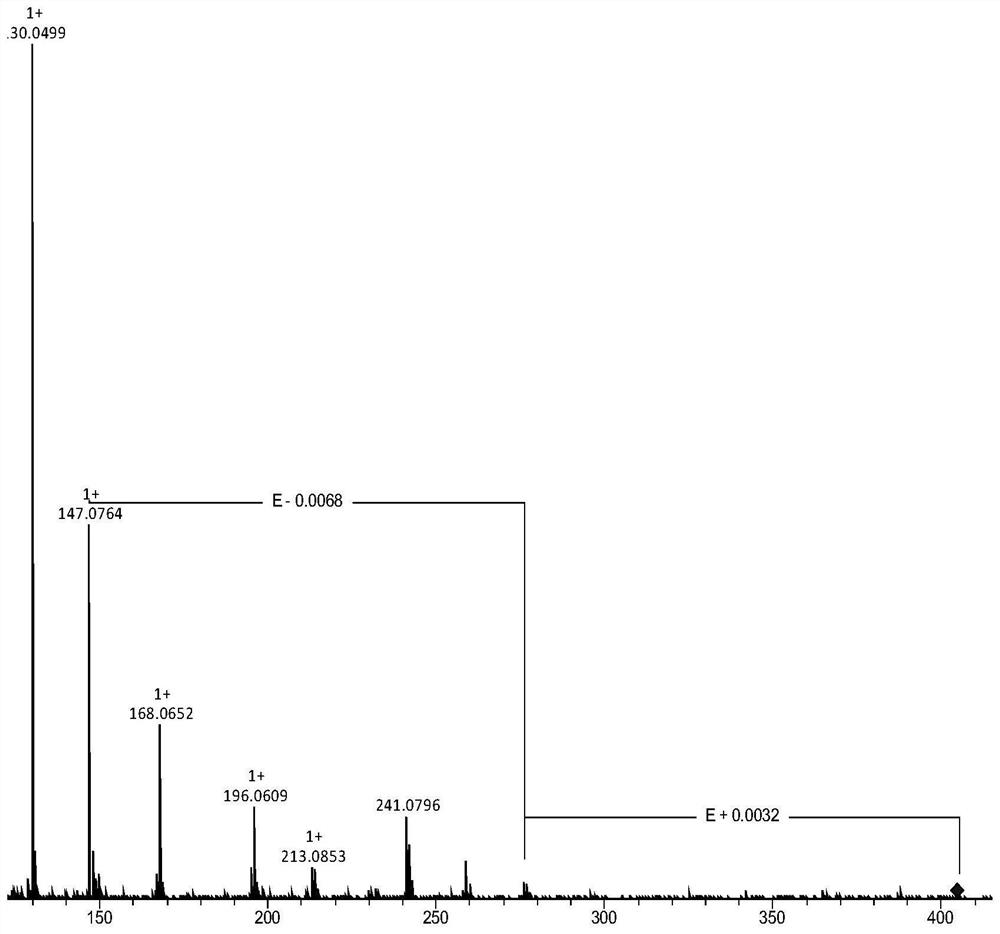

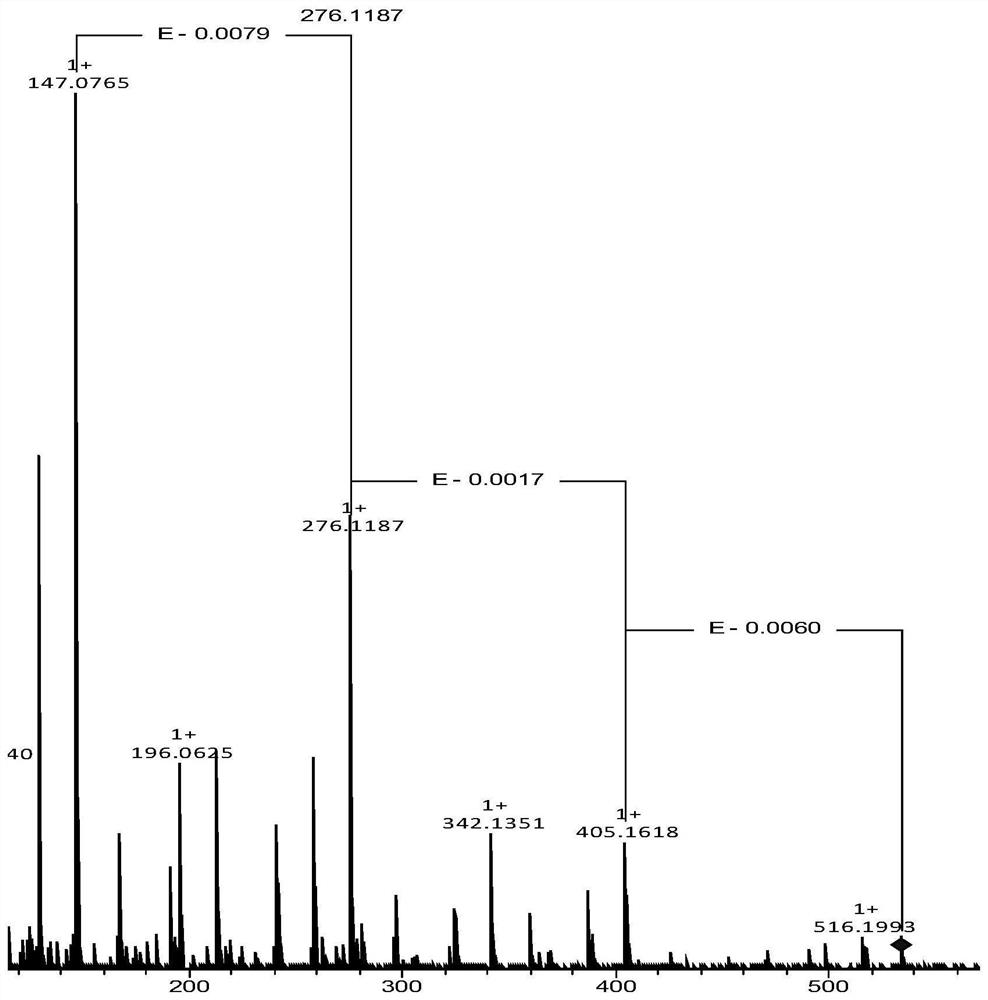

[0046] (1) Dissolve 50g of glutamine in 50g of water, adjust the pH to 12 with sodium hydroxide, add 0.1g of glutaminase, react at 37°C for 12h, inactivate the enzyme in boiling water for 20min, and then freeze-dry in a vacuum The improver was obtained by drying in medium for 48h, and the improver was analyzed by UPLC-MS / MS. It can be seen from Figure 1 that the modifier prepared in this example mainly includes γ-Glu-Gln, γ-Glu-γ-Glu-Gln, γ-Glu-γ-Glu-γ-Glu-Gln, γ-Glu-γ- Glu-γ-Glu-γ-Glu-Gln and γ-Glu-γ-Glu-γ-Glu-γ-Glu-γ-Glu-Gln. in, Figure 1a , Figure 1b , Figure 1c , Figure 1d and Figure 1e represent γ-Glu-Gln, γ-Glu-γ-Glu-Gln, γ-Glu-γ-Glu-γ-Glu-Gln, γ-Glu-γ-Glu-γ-Glu-γ-Glu-Gln and γ-Glu-γ-Glu-γ-Glu-γ-Glu-γ-Glu-Gln.

[0047] (2) Put 2.5g (0.5%, relative to flour) improver, 5g yeast, 100g white granulated sugar, 500g high-precision flour, 5g salt, 40g eggs and 300g water into the automatic dough making machine for mixing, and then The dough making machine first kne...

Embodiment 3

[0050] (1) Dissolve 50g of glutamine in 50g of water, adjust the pH to 12 with sodium hydroxide, add 0.1g of glutaminase, react at 37°C for 12 hours, inactivate the enzyme in boiling water for 20 minutes, and then freeze-dry in vacuum The improved agent was obtained by drying in the agent for 48 hours, and the improved agent was analyzed by UPLC-MS / MS. It can be seen from the UPLC-MS / MS diagram that the modifier prepared in this example mainly includes γ-Glu-Gln, γ-Glu-γ-Glu-Gln, γ-Glu-γ-Glu-γ-Glu-Gln, γ- Glu-γ-Glu-γ-Glu-γ-Glu-Gln and γ-Glu-γ-Glu-γ-Glu-γ-Glu-γ-Glu-Gln.

[0051] (2) Put 25g (5%, relative to flour) improver, 5g yeast, 100g white granulated sugar, 500g high-precision flour, 5g salt, 40g eggs and 300g water into the automatic dough making machine for mixing, and then mix them in the automatic dough making machine The production machine first kneads at a slow speed for 2 minutes, then kneads at a fast speed for 3 minutes; adds 40g of butter, then kneads at a slow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com