Industrial flue gas desulfurization and denitrification environment-friendly integrated tower

A technology for desulfurization, denitrification, and industrial flue gas, which is applied in gas treatment, chemical instruments and methods, and dispersed particle separation. time, and the effect of improving desulfurization and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

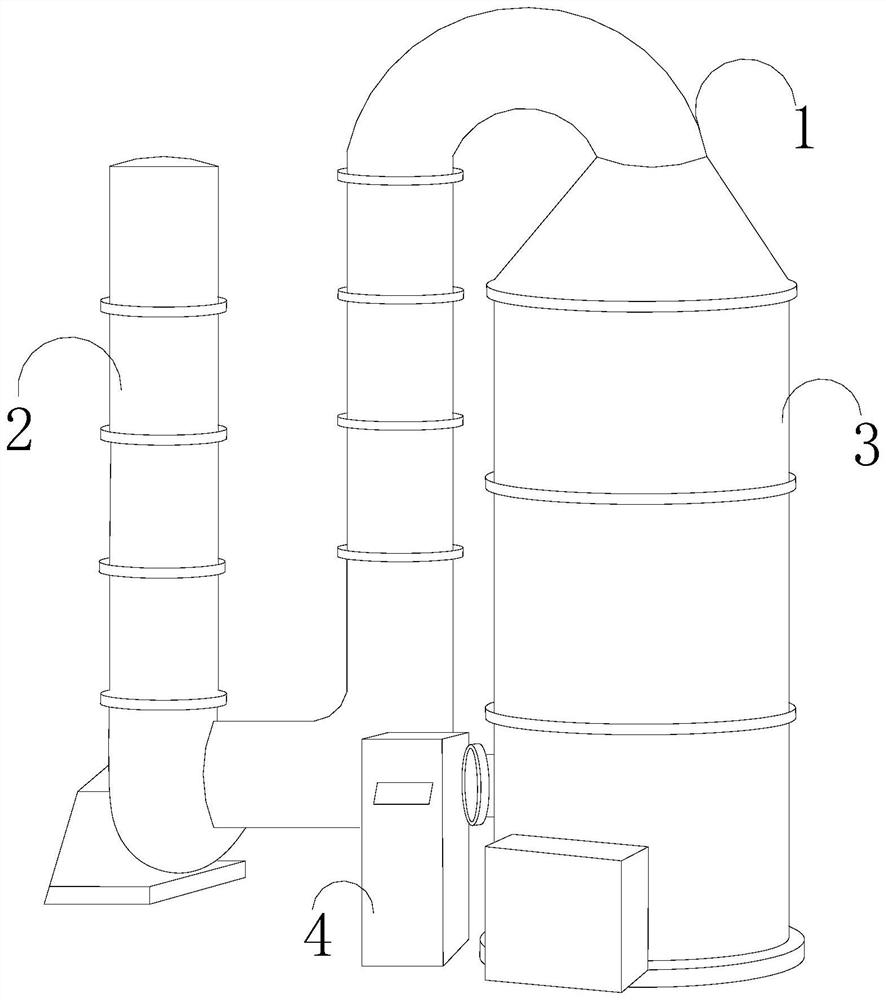

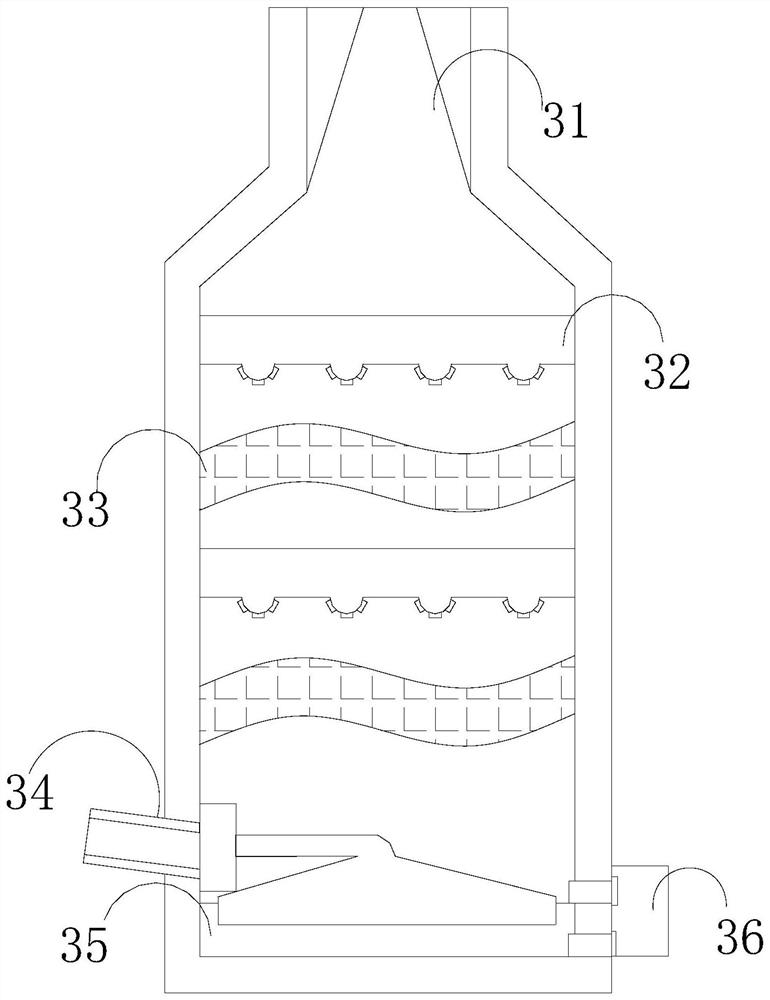

[0031] Such as Figure 1-Figure 4As shown, the present invention provides an industrial flue gas desulfurization and denitrification environmental protection integrated tower, its structure includes an output port 1, a conduit 2, a tower body 3, and a motor 4, and the output port 1 is installed between the conduit 2 and the tower body 3 , the tower body 3 is provided with a motor 4, and the motor 4 and the inside of the tower body 3 are electrically connected together, and the tower body 3 includes a discharge port 31, a shower 32, a filter bag 33, an inlet Pipeline 34, slurry tank 35, liquid collection tank 36, sprayer 32 and filter bag 33 are arranged below the discharge port 31, and discharge port 31 communicates with conduit 2, between the sprayer 32 and filter bag 33 Arranged at intervals, the inlet pipe 34 is installed on the inner wall of the tower body 3 and communicates with the slurry pool 35 at the bottom. One side of the slurry pool 35 is inserted and connected wit...

Embodiment 2

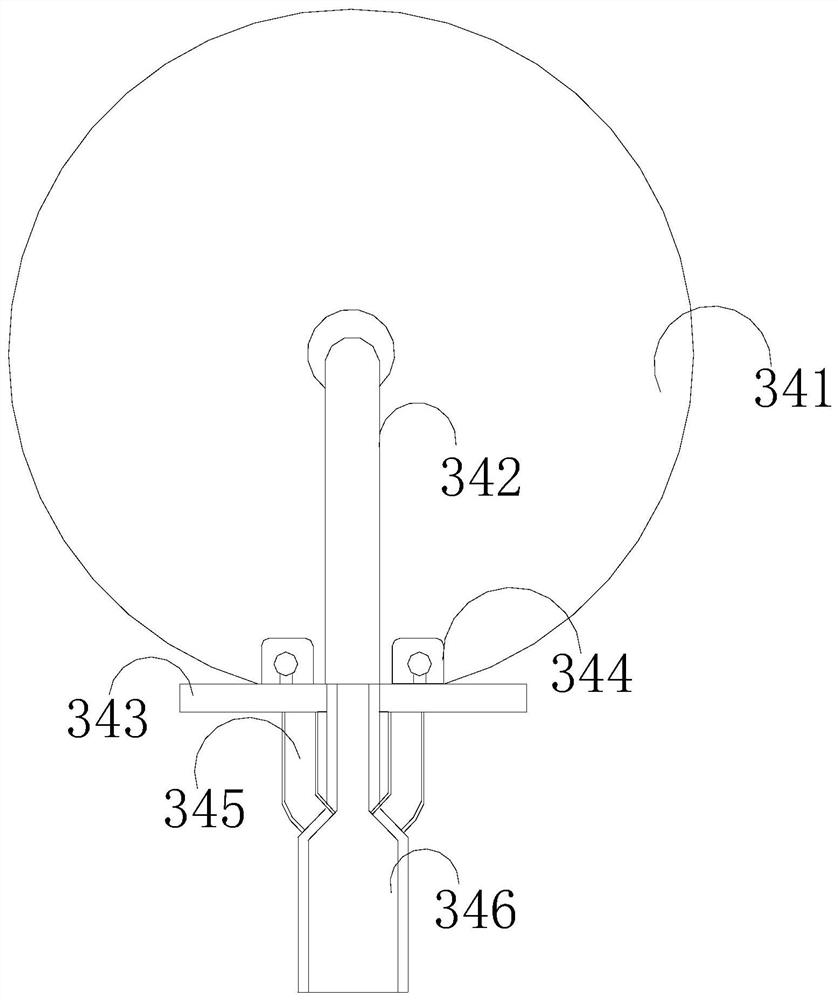

[0033] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The guide structure 416 includes an inlet 161, a frame 162, a brake sleeve 163, and a deflector 164. The inlet 161 and The contact end of the deflector 164 is provided with a brake sleeve 163, and the brake sleeve 163 is attached to the joint of the deflector 164. The four deflectors 164 are arranged along the inside of the frame 162 and form an integrated structure. The deflector 164 includes an auxiliary duct 641, a swirling plate 642, a conveying plate 643, a lower exhaust pipe 644, a partition device 645, and a positioning member 646. The included angles of the revolving plate 642 are fixedly connected to the conveying plate 643, the conveying plate 643 is provided with a partition device 645 and a positioning piece 646, and the two cooperate with each other, and the lower exhaust pipe 644 is symmetrically d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com