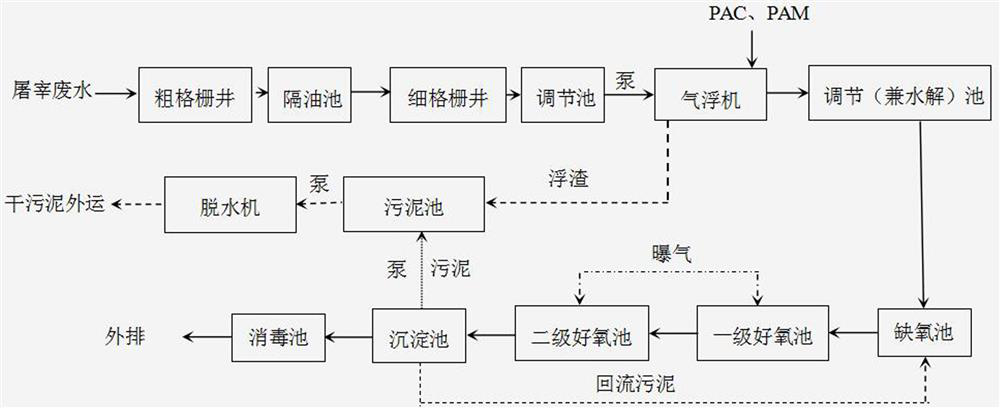

Slaughter house sewage treatment process

A sewage treatment and slaughterhouse technology, applied in water/sewage treatment, flotation water/sewage treatment, light water/sewage treatment, etc., can solve the problems of ineffective treatment and low removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

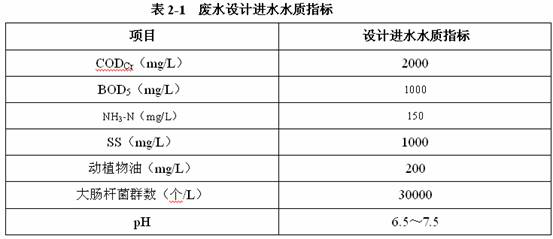

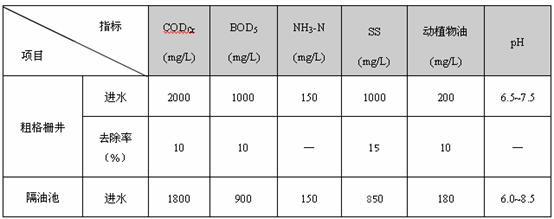

[0014] Source and nature of wastewater

[0015] The source of waste water for this project is mainly from the workshop, mainly including (1) waste water from washing livestock before slaughter; (2) waste water from scalding and carcass washing; (3) waste water from cleaning viscera; (4) waste water from washing workshop floor and utensils; ( 5) Waste water from flushing pens; (6) Waste water generated during meat processing. Slaughter wastewater has a high content of organic suspended matter and is easily corrupted. Discharging into water will consume dissolved oxygen in the water, destroy the ecosystem and pollute the environment. The water is reddish brown and has obvious fishy smell, which is a typical organic sewage. Sewage generally does not contain heavy metals, toxic chemicals, protein and grease, and high salt content.

[0016] Treated water volume

[0017] According to the information provided by the owner, the maximum amount of slaughtering wastewater produced in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com