A kind of RPC cover plate of tunnel cable trench and preparation method thereof

A tunnel cable and cover plate technology, applied in the field of building materials, can solve the problems of limiting the use of cable trench RPC cover plates, demanding impermeability requirements, low tensile strength, etc., achieving fewer defects, increased fluidity, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

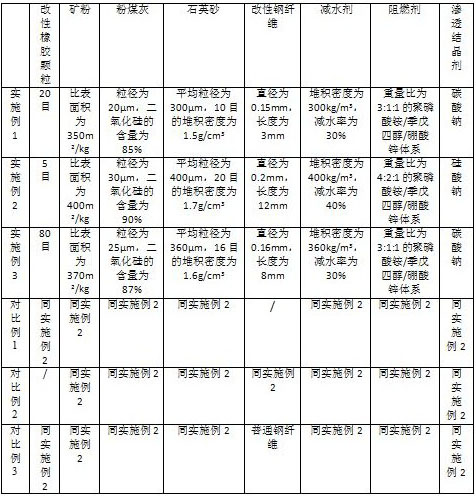

Examples

preparation example Construction

[0044] The preparation method of the tunnel cable trench RPC cover plate in the above-mentioned embodiment comprises the following steps:

[0045] (1) Add cement, mineral powder, fly ash, quartz sand, modified steel fiber, flame retardant, modified rubber particles and osmotic crystallizer into the mixer and mix at a speed of 255r / min for 15 minutes, then Add water reducer and water, stir evenly to get concrete slurry;

[0046] (2) Inject the concrete slurry into the mold, let it stand at room temperature for 5 hours, and then put it into the curing room with a temperature of 20°C and a relative humidity of 95% or more. Steam is introduced and the temperature is raised at a rate of 10°C / h until When the temperature reaches 35°C, take it out after curing for 20 hours, and cool it at room temperature;

[0047] (3) After the specimen is removed from the mold, it is moved into a high-temperature curing room, and the temperature is slowly and uniformly raised to 300°C within 6 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com