Indoor floor construction method and indoor floor structure applied thereto

A construction method and floor technology, which can be used in building structures, buildings, floors, etc., can solve problems such as poor use effect, and achieve the effect of good use effect, enhanced strength, and enhanced thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

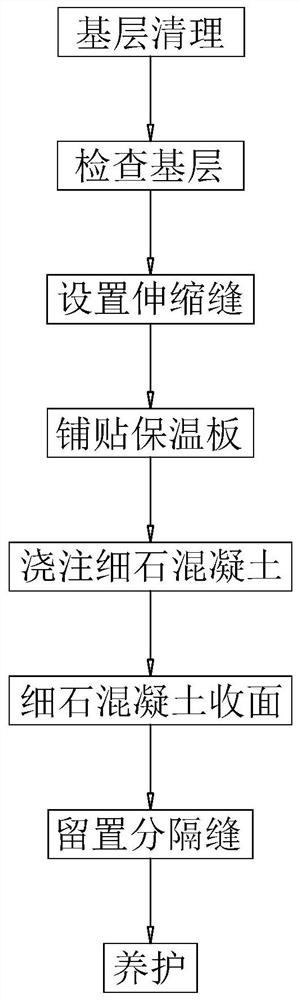

[0044] Embodiment 1 of the present application discloses an indoor floor construction method. refer to figure 1 , the method includes the following steps:

[0045] S1. Clean the base layer 1: Clean up the base layer 1 of the floor (including the base layer of the floor and the base layer of the wall at the corner), and remove the surface protrusions to make the base layer smooth and clean, and prevent the pollution of chemical substances such as paint;

[0046] S2. Check the base level 1: re-measure the elevation of the main floor, and determine the adjustment method according to the measurement results. If the deviation is large, make adaptive rectification to ensure that the floor size of the indoor main structure is reasonable after the construction is completed;

[0047] S3. Set up expansion joints 4: Make uninterrupted expansion joints 4 around the ground and at the junction of vertical components such as interior and exterior walls and columns. Expansion joints 4 are ma...

Embodiment 2

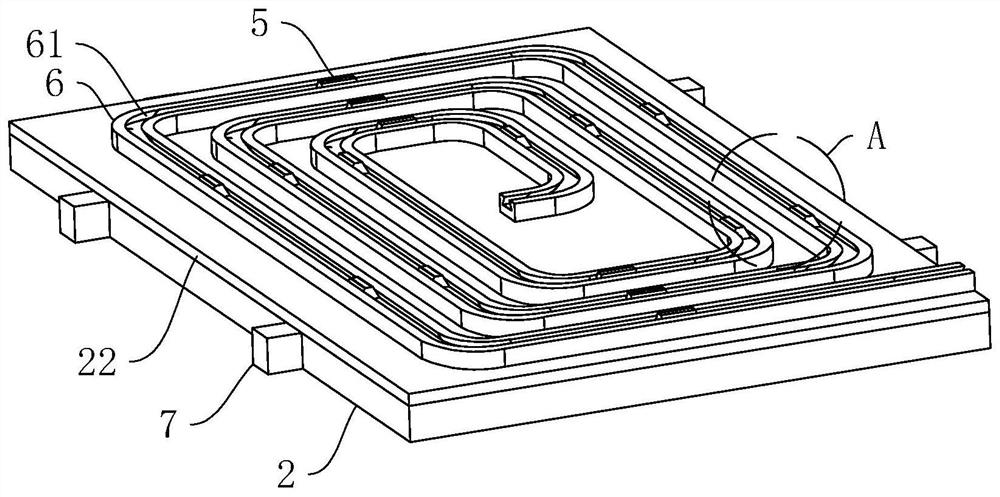

[0068] refer to Figure 4 and Figure 5 The difference between this embodiment and Embodiment 1 is that a reflective layer 22 is pasted on the side of the thermal insulation board layer close to the base layer 1, and the reflective layer 22 uses a floor heating reflective film to transfer the heat indoors to the base layer 1 through the thermal insulation board layer. The reflection is transmitted back to the room, thereby enhancing the indoor heat preservation effect and enhancing the use effect.

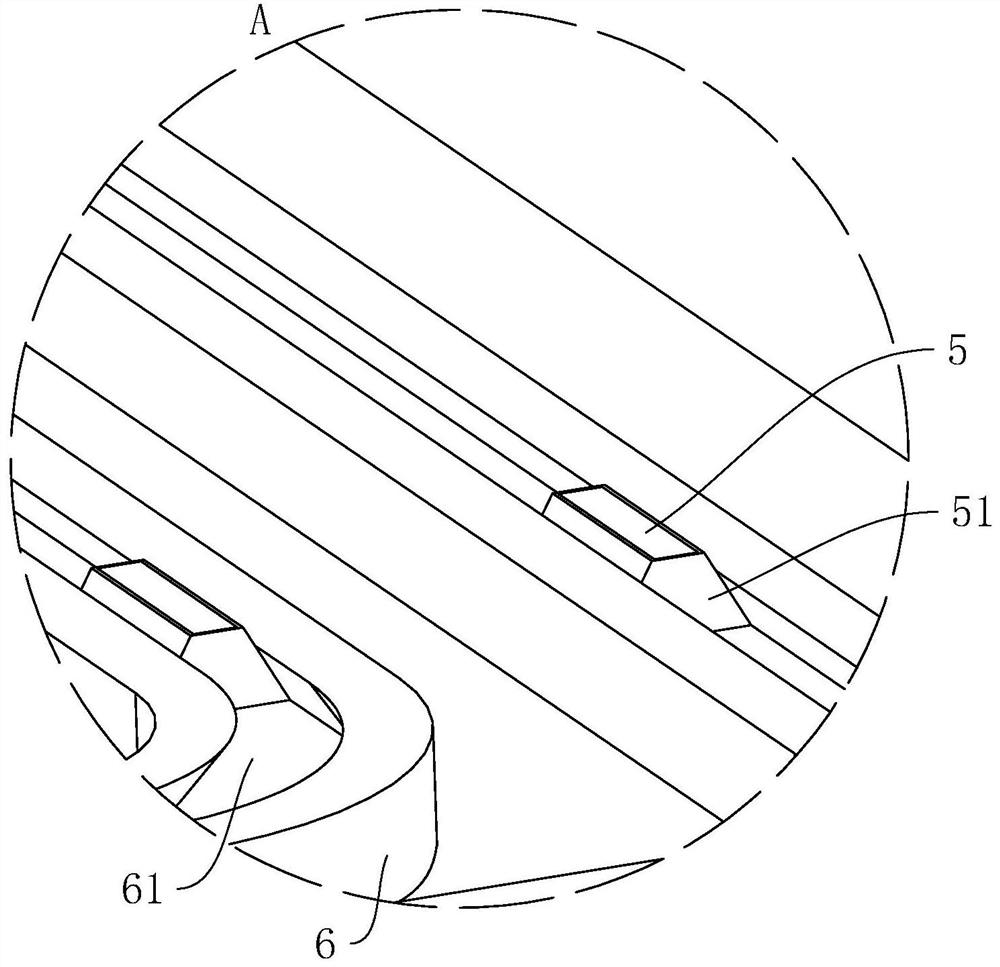

[0069] A plurality of reinforcing ribs 6 are fixed on the side of the insulation board layer close to the base layer 1, and the reinforcement ribs 6 pass through the reflective layer 22 and are fixed on the insulation board 2 to enhance the structural strength of the entire insulation board 2, thereby relatively prolonging the service life of the insulation board layer The reinforcing rib 6 is fixed on the insulation board 2 in a back-shaped structure, and a chute 61 is provided o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com