Continuous organic fiber wear resistance tester

A technology of organic fiber and abrasion resistance, which is applied in the field of testing and evaluation of organic fibers, can solve the problems that the abrasion resistance of twisted fibers is difficult to test, increase the selectivity of test conditions, and reduce the limitations of instruments, etc., so as to solve the problem of abrasion resistance Difficult to test, less restrictive, more selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

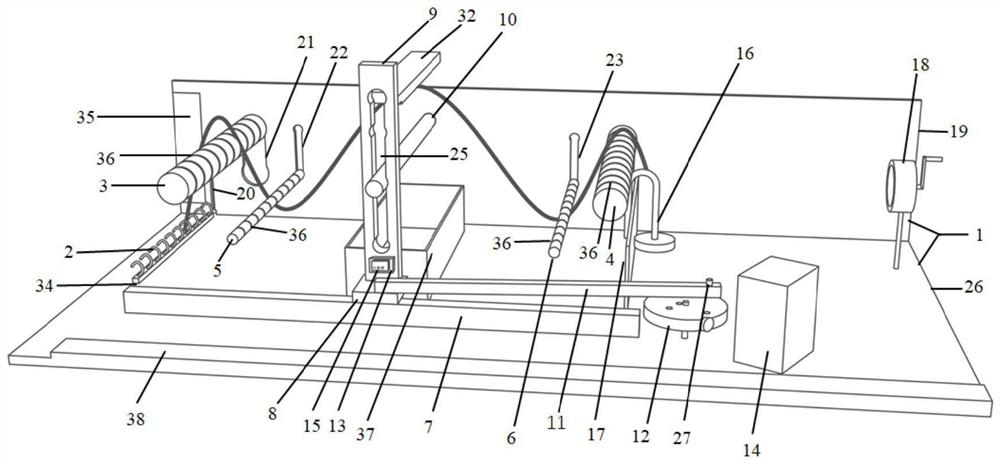

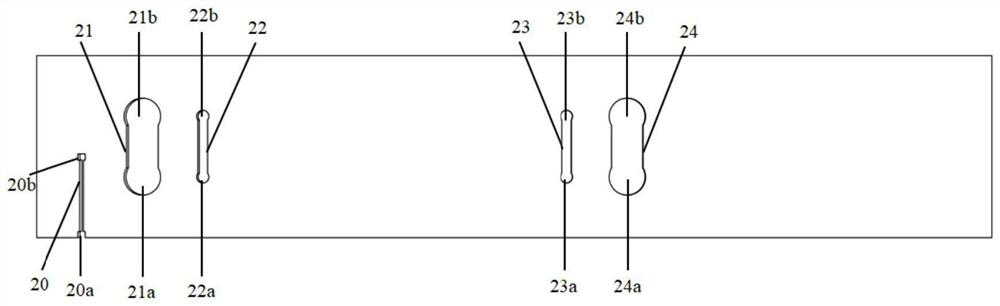

[0067] Embodiment 1: no twisting

[0068] The test sample is two kinds of PTFE fibers, the linear density is about 450dtex, the abrasive on the grinding roller is 500 mesh water sandpaper, and the grinding roller is a smooth cylindrical grinding roller with a diameter of 2cm. The grinding roller does not rotate, but only reciprocates. The rubbing speed is 60 times / min, the rubbing distance is 5cm, the rubbing angle is 120°, the mass of the weight on the U-shaped hook is 45g, and the fiber is not twisted. Wrap 500 mesh water sandpaper on the surface of the grinding roller, and the sample fiber according to figure 1 Wrap it on the abrasion resistance tester as shown, and carry out 5 tests according to the above parameters. The test conclusions are shown in Table 1. It can be seen from Table 1 that the number of reciprocations of the grinding roller when the 1# PTFE fiber is broken is greater than the number of reciprocating times of the grinding roller when the 2# PTFE fiber is...

Embodiment 2

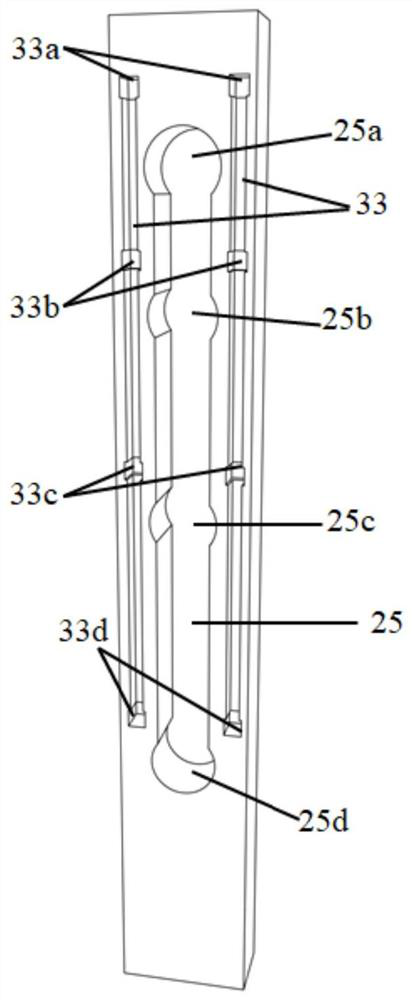

[0072] The test sample is 1#PTFE fiber, the linear density is about 450dtex, the abrasive on the grinding roller is 500 mesh water sandpaper, and the grinding roller is a smooth cylindrical grinding roller with a diameter of 2cm. The grinding roller does not rotate, but only reciprocates. The rubbing speed is 60 times / min, the rubbing distance is 5cm, the rubbing angle is 120°, and the mass of the weight on the U-shaped hook is 45g. image 3 Twisting is carried out as shown, and the fiber twists are 0 twist, 50 twist, and 100 twist respectively. Wrap the 500-mesh water sandpaper on the surface of the grinding roller, and the sample fiber according to figure 1 Wrap it on the abrasion resistance tester as shown, and carry out 5 tests according to the above parameters. The test conclusion is shown in Table 2. As can be seen from Table 2, the number of reciprocations of the grinding roller when the 1# PTFE fiber breaks without twisting is greater than the number of reciprocations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com