Optical fiber movable connector

A technology of movable connectors and optical fibers, applied in the directions of light guides, optics, instruments, etc., can solve the problems of high cost, large tube holes, large overall length and outer diameter, etc., and achieve the effects of cost saving, convenient disassembly and assembly, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

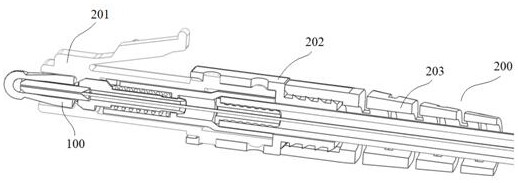

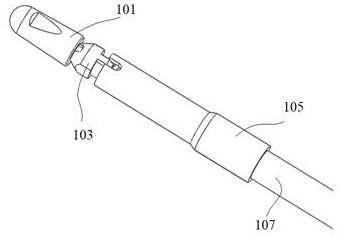

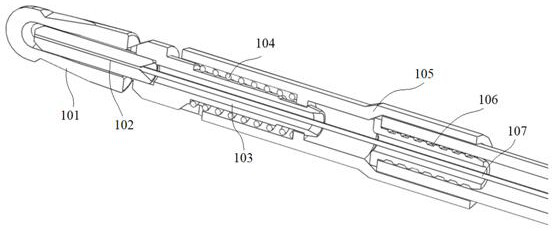

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] The general idea of the present invention is based on the principle of the traditional pipe penetrator, using the existing air blowing micropipe and the principle of deployment, and using the optical fiber flexible connector as a pipe penetrator to pass through the micropipe and then assemble a technical solution .

[0025] The head of the traditional pipe threader is composed of a guide head and a cable. The guide head is a pointed shape with a through hole in the middle for easy threading. The cable is crimped in the guide head, and the cable is a flexible metal or plastic tube. The principle of the multi-purpose SC-type connector through the tube in the prior art is to make the traditional connector into a three-layer structure, which are the outer shell, the inner sleeve, and the optical cable assembly. When wrapping it first, pull the tail slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com