Metal-halide lamp

A metal halide lamp and halide technology, applied in discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve problems such as blackening of discharge tube walls, end of lamp life, and discharge tube corrosion, etc. The effect of black reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

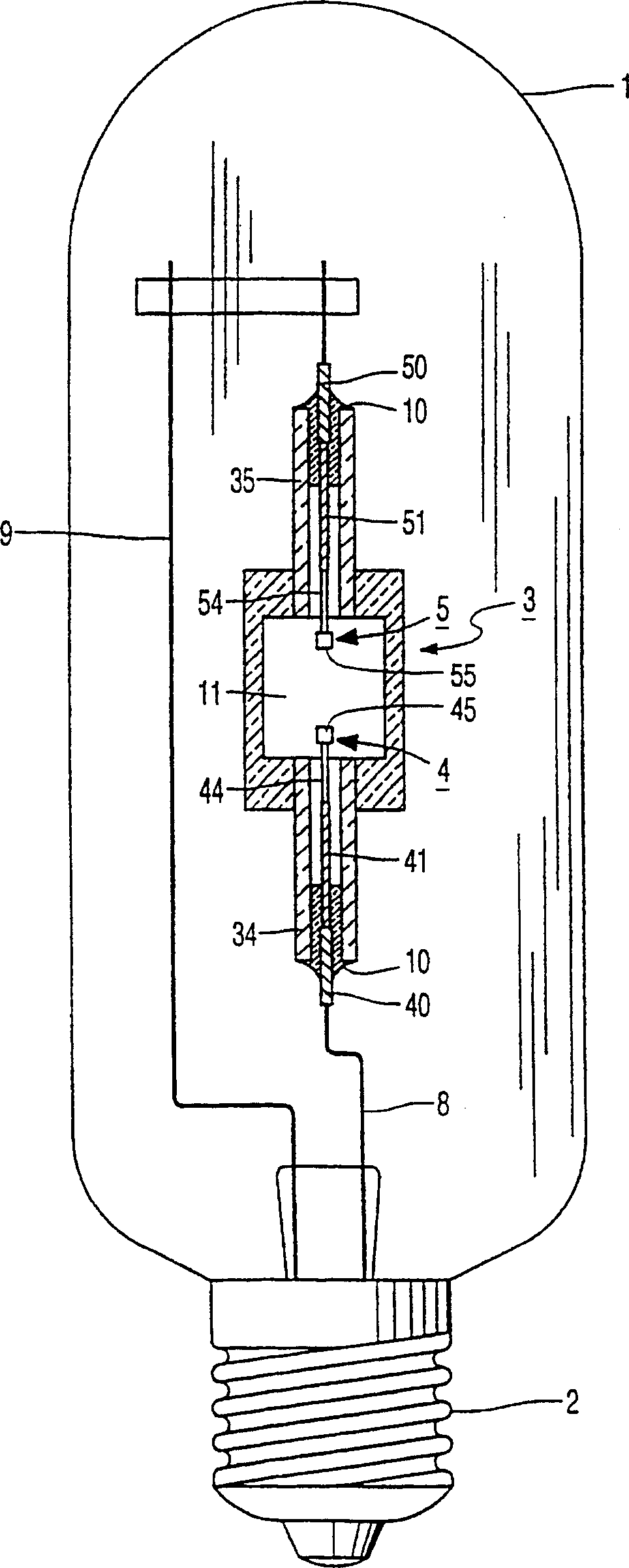

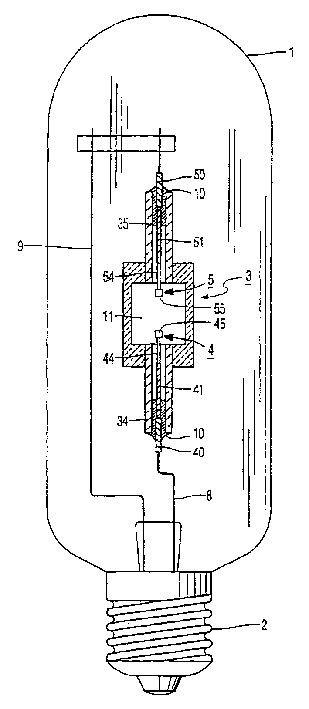

[0014] attached figure 1 A metal halide lamp is shown with the discharge vessel in section, but not to scale, with ceramic walls enclosing a discharge space 11 containing an ionizable filling, which in this case contains not only Hg but also Na and Tl halide. The packing also includes an oxygen distributor comprising CaO, eg in the form of a CaO-impregnated ceramic support. The two electrodes 4, 5 in the figure have electrode rods 44, 54 and top ends 45, 55, both of which are composed of W, and are arranged in the discharge tube. The discharge tube is closed on one side by ceramic protruding plugs 34, 35 on the electrodes 4, 5 arranged in the discharge tube, and the protruding plugs are respectively closely surrounding the lead wires 40, 41, 50, 51 according to a certain gap, and are close to the end of the discharge tube A fused ceramic joint 10 is connected thereto in an airtight manner. The structure of the discharge vessel itself is known, for example from EP-0 587 238 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com