Soil flat laying equipment for garden breeding and application method of soil flat laying equipment

A soil and garden technology, applied in the field of municipal garden plant planting, can solve the problems of uneven size, uneven material of seedling blocks, time-consuming and labor-intensive, etc., and achieve the effect of improving the utilization rate and improving the screening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

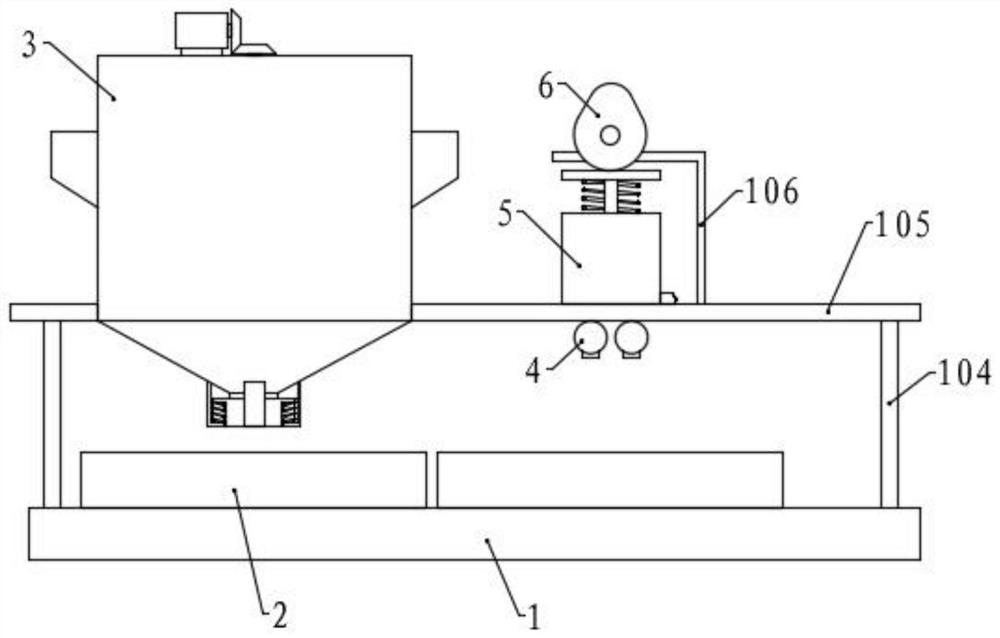

[0057] Referring to the accompanying drawings, the present invention provides a technical solution: a soil paving equipment for garden breeding, including a conveying assembly 1, the conveying assembly 1 includes two side plates 101 arranged symmetrically, between the two side plates 101 A plurality of conveying rollers 102 are evenly arranged and rotatably connected, and the two ends of the conveying rollers 102 are rotationally connected with the side plates 101 on both sides. The conveying rollers 102 are jointly provided with a conveying belt 103, and one end of one of the conveying rollers 102 is connected with a motor , the top of the side plate 101 is symmetrically fixed with support rods 104, the tops of the four support rods 104 are jointly fixed with a top plate 105, the left side of the top plate 105 is fixed with a material storage box 3, and the right side is provided with a sprinkler mechanism;

[0058] One side of the top surface of the material storage box 3 is ...

Embodiment 2

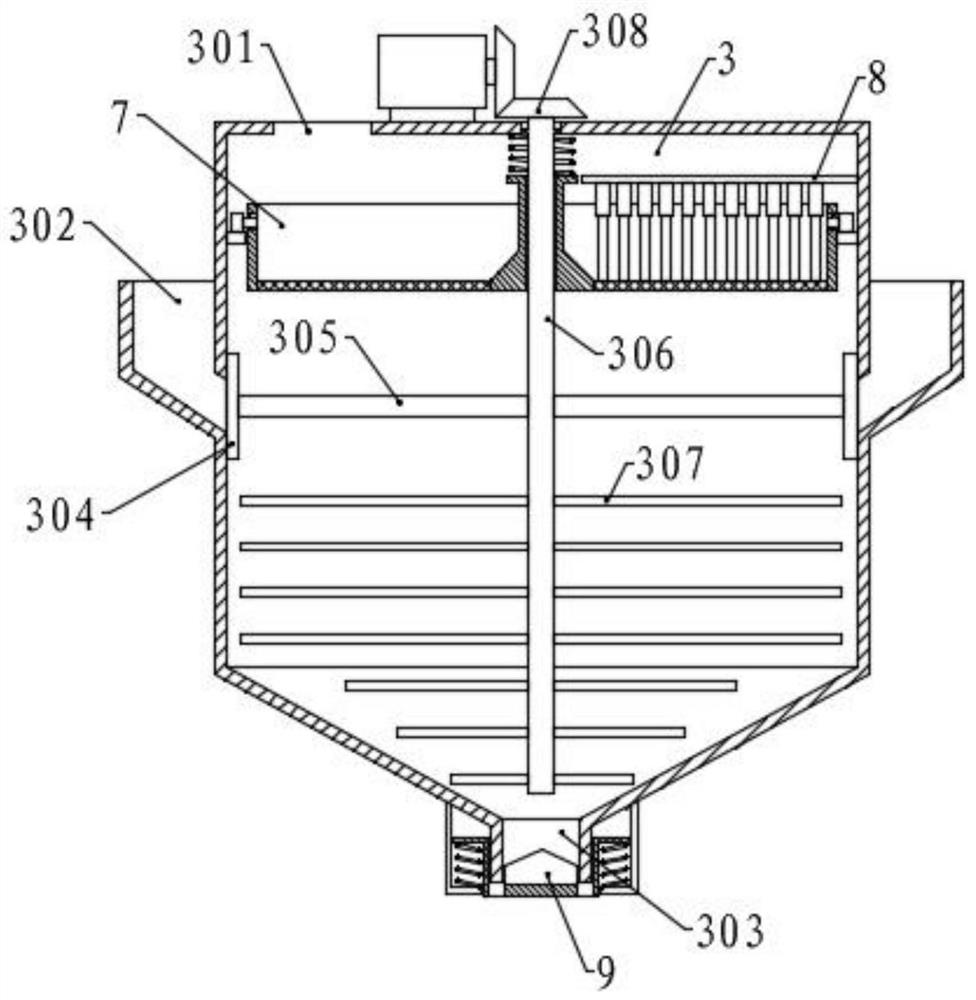

[0071] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a plurality of feeding hoppers 302 are evenly arranged on the side wall of the middle part of the material storage box 3 along the circumferential direction, and a plurality of connecting rods 305 are correspondingly fixed on the main shaft 306, The outer end of the connecting rod 305 is fixed with an arc-shaped sealing plate 304, the sealing plate 304 corresponds to the feed hopper 302 one by one, and is slidably connected with the side wall of the material storage box 3, and the bottom of the main shaft 306 is evenly fixed along the circumferential direction. A stirring blade 307.

[0072] Store other raw materials through the feed hopper 302, and drive the sealing plate 304 to rotate during the rotation of the main shaft 306, so that the sealing plate 304 intermittently opens each lower hopper, adds other materials to the material storage box 3, and passes through th...

Embodiment 3

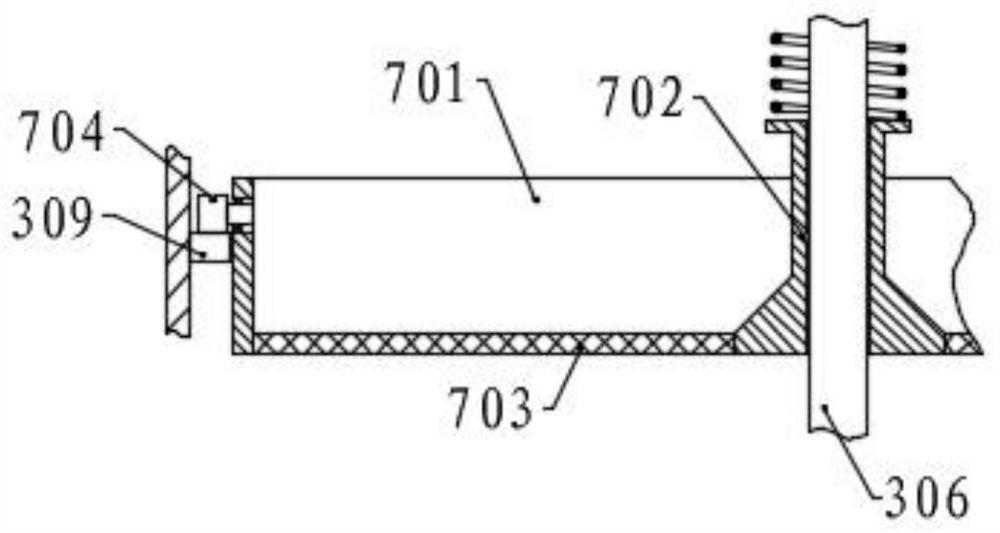

[0074] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that a gear shaft 606 is rotatably connected to the third bracket 107. The gear shaft 606 is coaxially arranged with the rotation shaft 604. The gear shaft 606 is close to one end of the rotation shaft 604. A connecting cylinder 605 is provided, and the other end of the connecting cylinder 605 is sleeved on the rotating shaft 604. A plurality of first locking teeth are evenly fixed on the gear shaft 606 along the circumferential direction, and a plurality of teeth are arranged on the inner wall of the connecting cylinder 605 correspondingly. There are a plurality of second locking teeth correspondingly provided on the rotating shaft 604, and the outer sections of the second locking teeth are symmetrically provided with guide surfaces, and the ends of two adjacent locking slots in the connecting cylinder 605 are also correspondingly provided with symmetrical Inclined guide su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com