Self-extrusion deoiling oil-containing waste gas filtering pipeline

A waste gas filtration and self-extrusion technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of easy clogging of filtration equipment, waste of water resources, and reduce the efficiency of oily waste gas treatment, so as to improve the extrusion efficiency. The effect of deoiling by pressure and the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

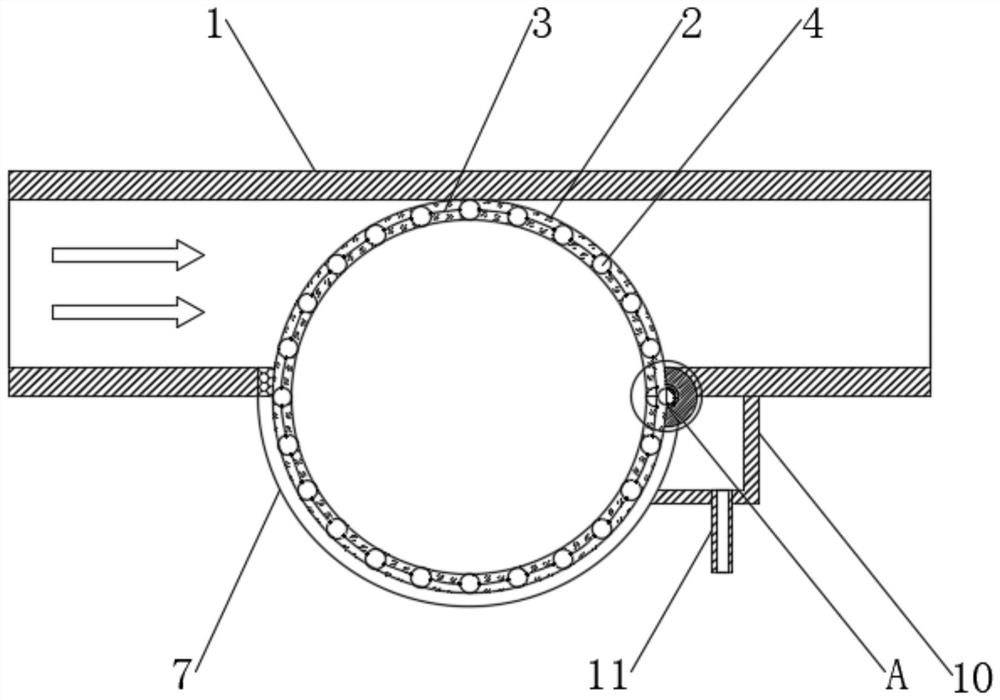

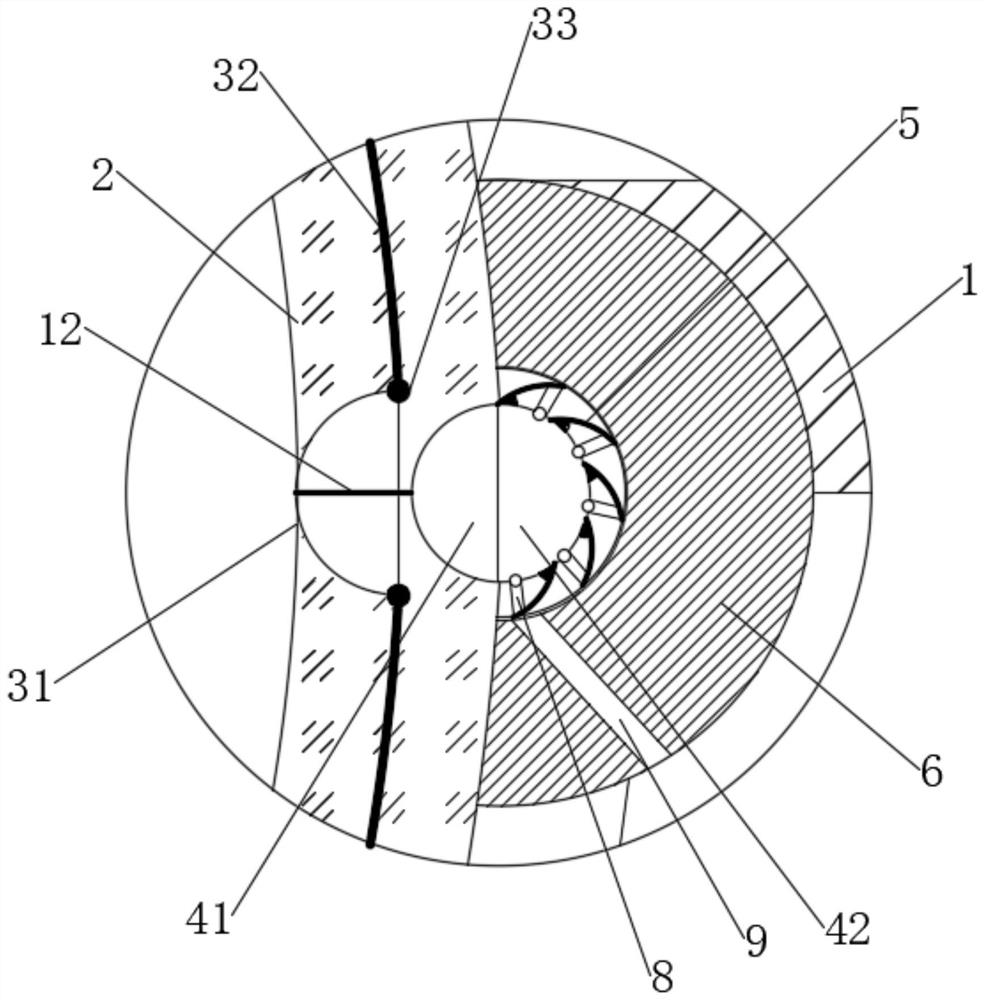

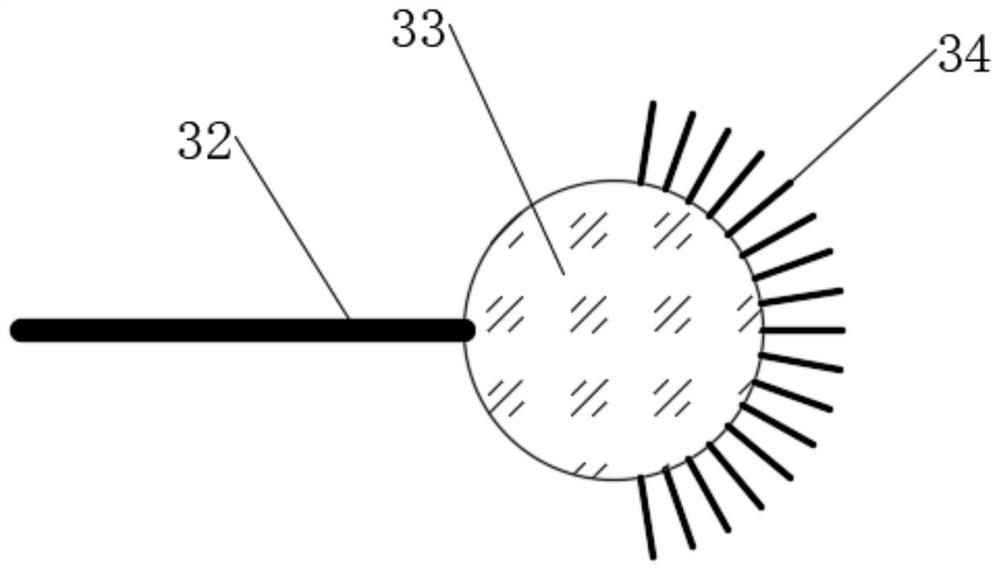

[0041] see Figure 1-2 , a self-squeezing deoiling oily waste gas filtration pipeline, comprising a filter tube 1, the lower end of the filter tube 1 is provided with a rotation hole, an isolation half cylinder 7 is connected to the outside of the rotation hole, and a rotation oil suction cylinder 2 is connected to the rotation of the isolation half cylinder 7 , the self-rotating oil suction cylinder 2 is inlaid with a plurality of evenly distributed oil transfer nets 3, and the oil transfer net 3 is provided with a self-squeezing oil collection ball 4, and the self-squeezing oil collection ball 4 and the oil transfer net 3 are connected with The elastic pull cord 12, the self-extruding oil-collecting ball 4 includes a weak magnetic hemisphere 41 and an oil-collecting hemisphere 42 integrally connected, and the outer surface of the oil-collecting hemisphere 42 is connected with a plurality of densely distributed magnetic control coating petals 5, and the magnetic control The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com