Automatic control method for pipeline purging in caustic soda production

A technology of automatic control and start-up control, applied in the direction of chemical instruments and methods, program control, comprehensive factory control, etc., can solve the problems of human error-prone, labor-intensive labor, high production operation requirements, etc., to reduce the number of human operations , Improve the degree of automation and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

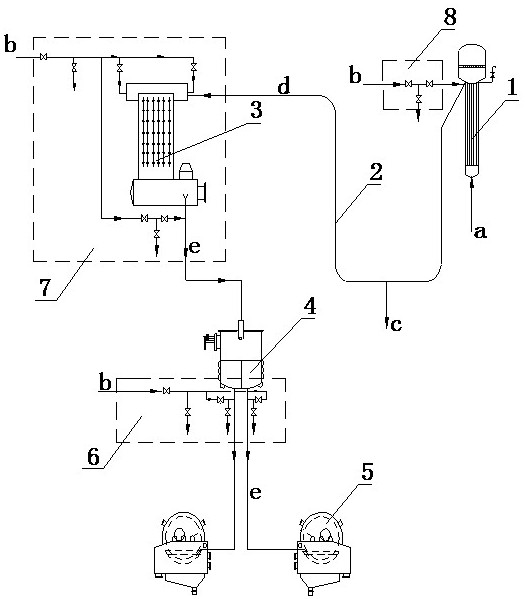

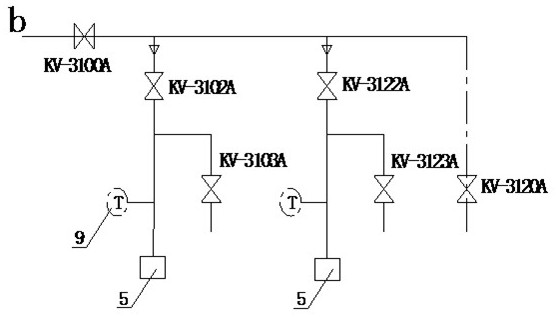

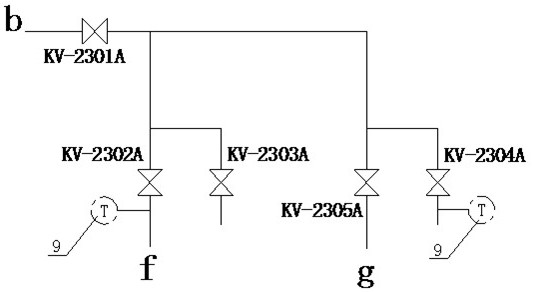

[0026] As shown in Figure 1-5, an automatic control method for pipeline purge in caustic soda production, including an operation station with two-way electrical connection and a production site control terminal; the operation station is equipped with a one-key purge start control button; the production site control terminal includes Rising film concentrator (1), U-shaped elbow (2), final concentration (3), distributor (4), caustic soda machine (5) connected in sequence; between the outlet of the distributor and the inlet of the caustic soda machine A caustic soda machine purge control unit (6) is set; a final concentration bottom purge and steam seal switch control unit (7) is set between the final concentration alkali inlet and the final concentration bottom outlet; Membrane concentrator outlet pipeline purge control unit (8); when the caustic soda production system stops, the operator at the operation station presses the one-button purge start control button, and the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com