Automatic demolding device for aluminum material machining

An automatic demoulding and aluminum material technology, applied in metal processing equipment, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of low work efficiency, low degree of automation, waste of manpower, etc., to improve work efficiency and automation High degree of manpower and time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

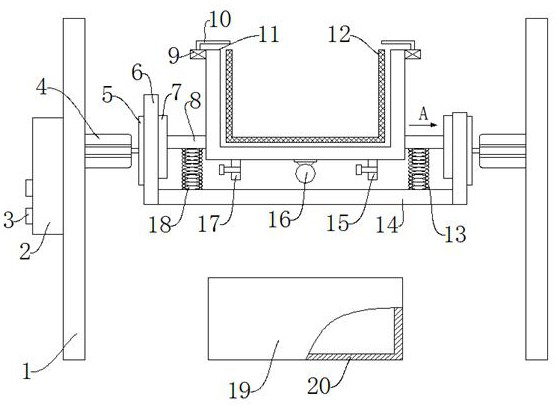

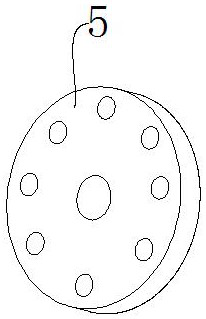

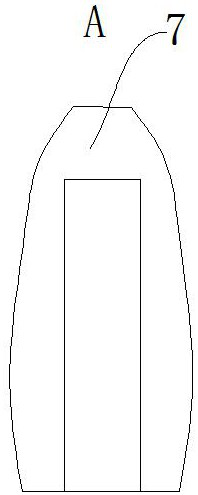

[0033] Such as Figure 1-Figure 4 As shown, an automatic demoulding device for aluminum processing includes a column 1, a control box 2, an operation button 3, a first motor 4, and a connecting disc 5. A control box 2 is arranged on one side of the column 1, and the control box 2 is An operation button 3 is provided, a first motor 4 is provided on the other side of the column 1, and the first motor 4 is used to provide power. One side of the first motor 4 is provided with a connecting disc 5, and one side of the connecting disc 5 is provided Side plate 6 is arranged, and one side of side plate 6 is provided with slideway 7, and the lower end of side plate 6 is provided with bottom plate 14, and one side of slideway 7 is provided with connecting baffle plate 8, and one side of connecting baffle plate 8 is provided with take-off Die bucket 11, demoulding bucket 11 is used for containing mold 12, and the inboard of demoulding bucket 11 is provided with mold 12, and the lower end ...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is:

[0036] The column 1 and the control box 2 are connected by screws, which make it easy to install and fix. The column 1 and the first motor 4 are connected by bolts, which ensure a certain connection strength and are easy to disassemble and connect the baffle. 8 and block 18 are connected by welding, which makes the connection between the two tight and firm.

[0037]Working principle: connect the water inlet pipe 15 with the external water source, inject cooling water into the gap between the demoulding barrel 11 and the mold 12, after a period of time, open the water outlet pipe 17, drain the moisture inside the demoulding barrel 11, and start Vibrating motor 16, under the action of vibrating motor 16, mold 12 reciprocates up and down in the demoulding barrel 11, finally separates from demoulding barrel 11, closes vibrating motor 16, starts second motor 9, and second motor 9 rotates to drive the rotating bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com