Coarse and fine double-layer external filtering equipment for cutting fluid of metal cutting machine tool

A metal cutting and cutting fluid technology, which is applied in metal processing equipment, metal processing machinery parts, filtration and separation, etc., can solve the problems of reduced cooling and lubrication effect, reduction of filter plate filtration effect, consumption, etc., to reduce a large number of reproduction and proliferation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

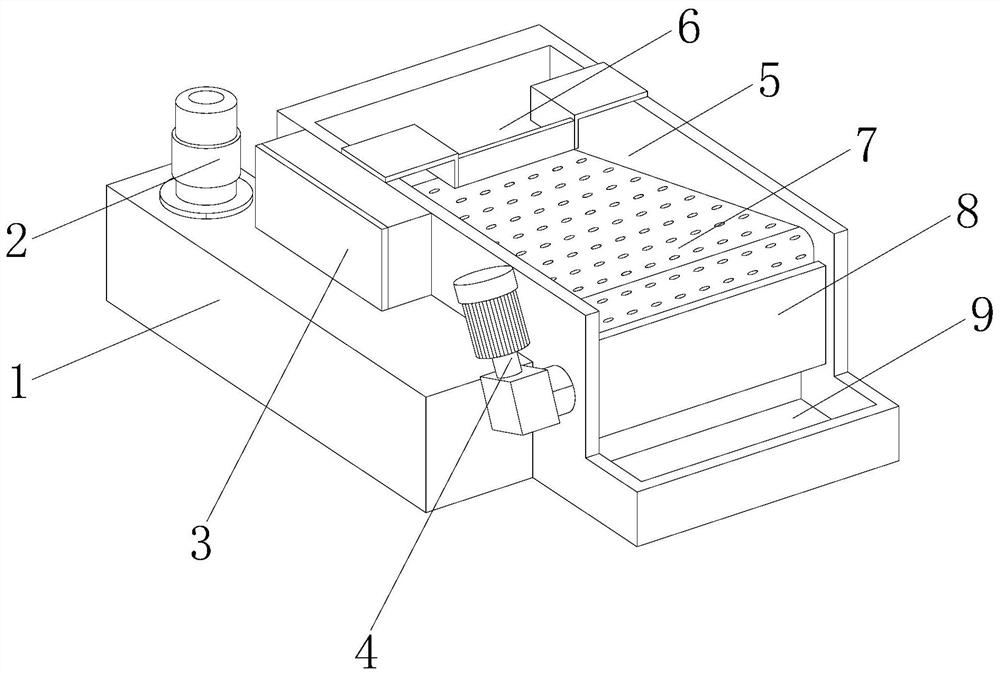

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The present invention is a metal cutting machine tool cutting fluid coarse and fine double-layer external filtering equipment, the structure of which comprises a water tank 1, a water pump 2, an electric control box 3, a motor 4, a filter box 5, an injection port 6, a filter plate 7, and a shielding plate 8 , filter residue collection box 9, the water pump 2 is embedded and installed on the top of the water tank 1, the upper end of the water tank 1 is provided with an electric control box 3, the motor 4 is installed on the left front surface of the filter box 5, and the injection port 6 is located at Above the end of the filter box 5, the filter plate 7 is installed inside the filter box 5, the baffle plate 8 is located at the front end of the filter plate 7, and the baffle plate 8 is welded inside the filter box 5, and the filter residue collection box 9 is embedded and installed in the The filter box 5 is belo...

Embodiment 2

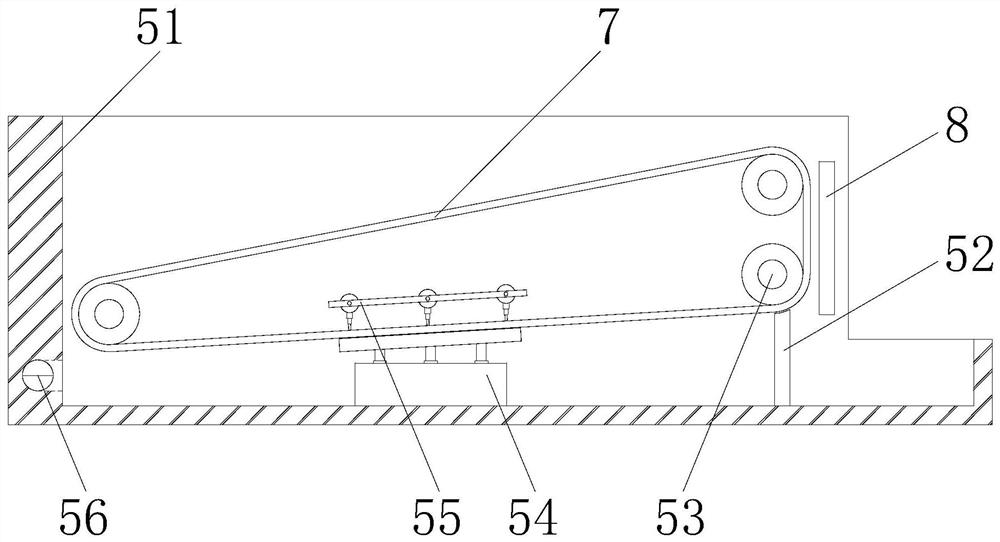

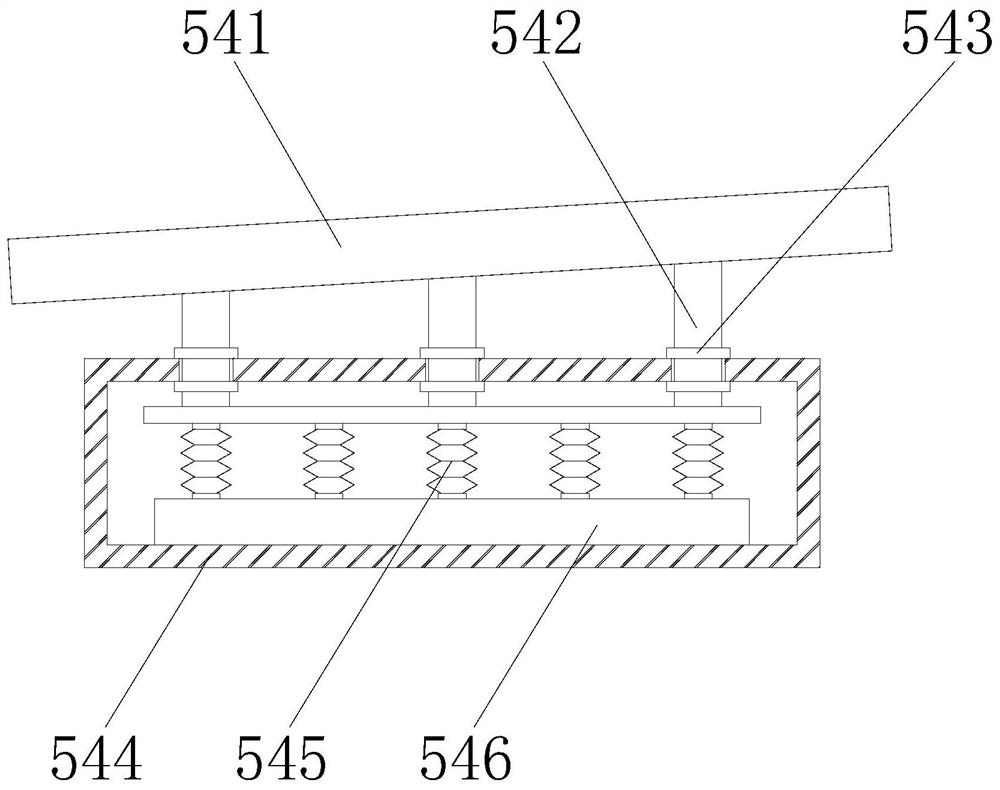

[0034] as attached Image 6 to attach Figure 9 Shown:

[0035] Wherein, the degerming mechanism 55 includes a mounting bar 551, a connecting shaft 552, a support rod 553, and a socket mechanism 554. The mounting bar 551 is welded on the inner wall of the box body 51, and the mounting bar 551 is connected to the supporting body through the connecting shaft 552. The rods 553 are axially connected, and the lower end of the support rod 553 is provided with a socket mechanism 554, and the socket mechanism 554 is located above the filter plate 7. There are three support rods 553, which are distributed on the installation bar 551 at a laterally inclined angle. And the angle of inclination is consistent with the angle of inclination of the lower end of the filter plate 7, and ten socket mechanisms 554 are equidistantly distributed on the lower end of each support rod 553, which is beneficial to dredge the bacteria that are blocked inside the filter holes on the surface of the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com