Alloy steel high-speed rail axle and production method thereof

A production method and technology of alloy steel, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems that cannot meet the application requirements of high-speed rail axles, low fatigue performance, etc., and achieve good and uniform cooling, high phase transition temperature, hardness and strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

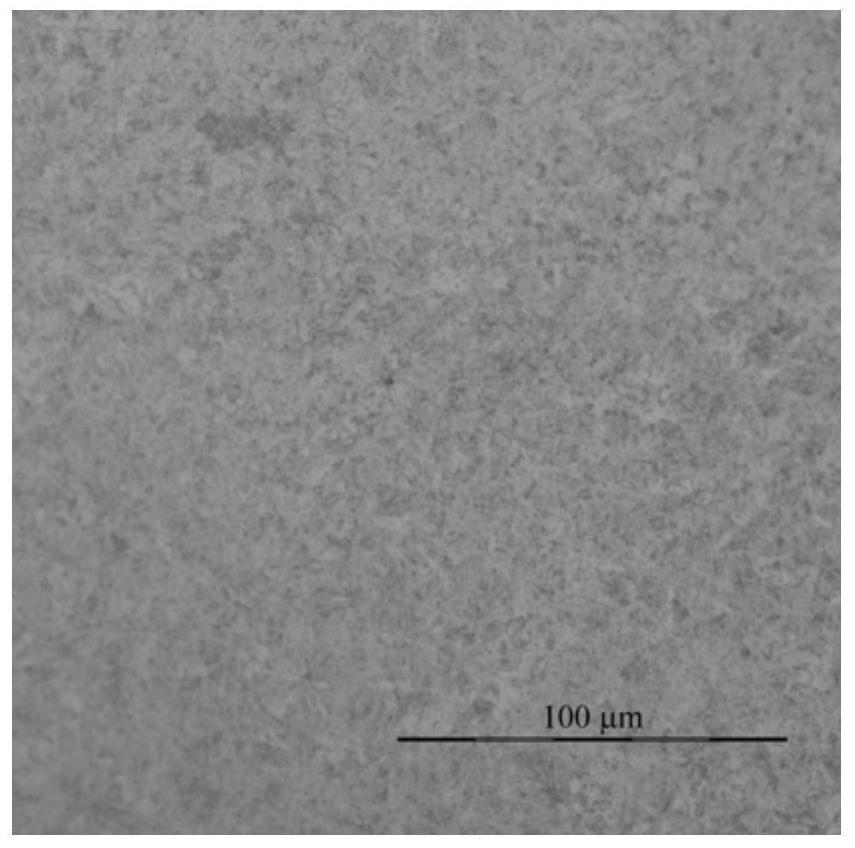

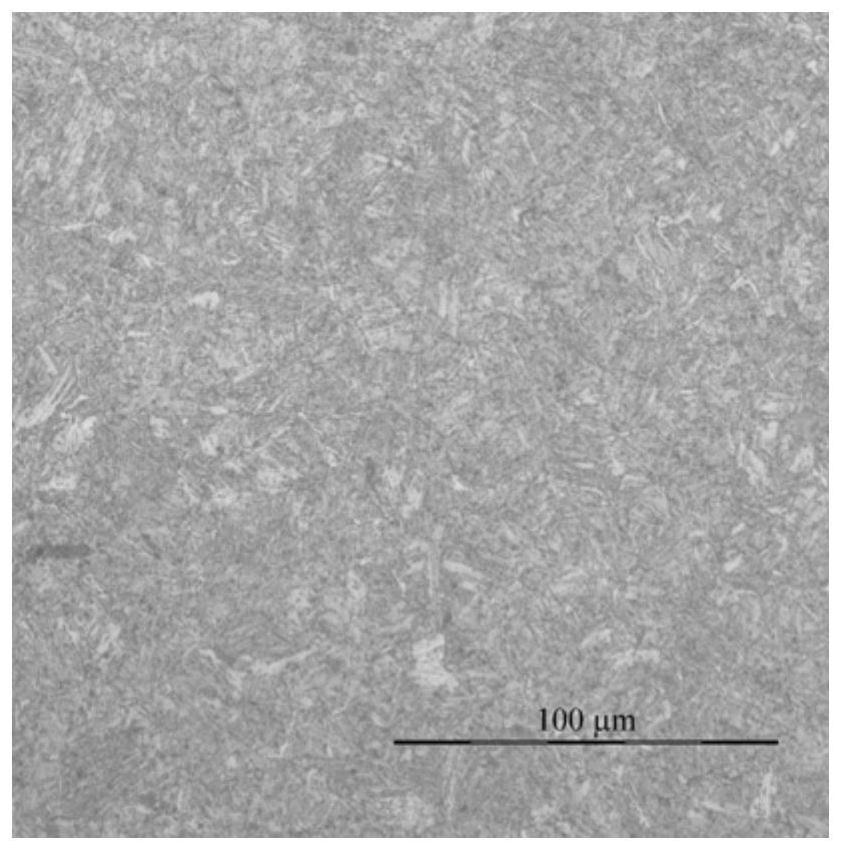

Image

Examples

Embodiment 1

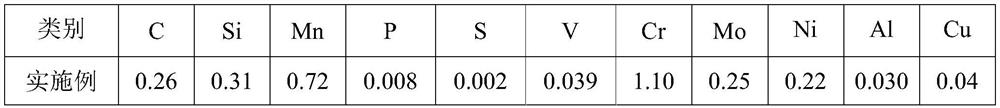

[0038] An alloy steel high-speed iron axle, including the following mass percentage components: as shown in Table 1, the balance not listed in Table 1 is Fe and unavoidable impurities.

[0039] Table 1 embodiment and comparative example chemical composition (unit: wt %)

[0040]

[0041]

[0042] The production method of the alloy steel high-speed rail axle comprises the following technological process:

[0043] Axle blank forging→rough turning of rough axle→axle end face processing→heat treatment→axle outer circle finishing turning→axle inner hole boring processing→cylindrical grinding→flaw detection→laser quenching→cylindrical grinding.

[0044] The heat treatment includes normalizing, quenching and tempering, specifically:

[0045] Normalizing process: heating the steel for high-speed rail axles to 920°C, keeping it warm for 6 hours, then air cooling to below 300°C;

[0046] Quenching process: heat the high-speed rail axle steel after normalizing to 900°C, keep it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com