Liquid level detection circuit module based on MCU

A liquid level detection and circuit module technology, which is applied in the field of sampling needles, can solve the problems of misjudgment of whether the sampling needle is in contact with the sample liquid surface, increase the cross-contamination of the test object, and greatly fluctuate the capacitance value. Anti-interference ability, fast sampling speed, and the effect of suppressing radiation interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

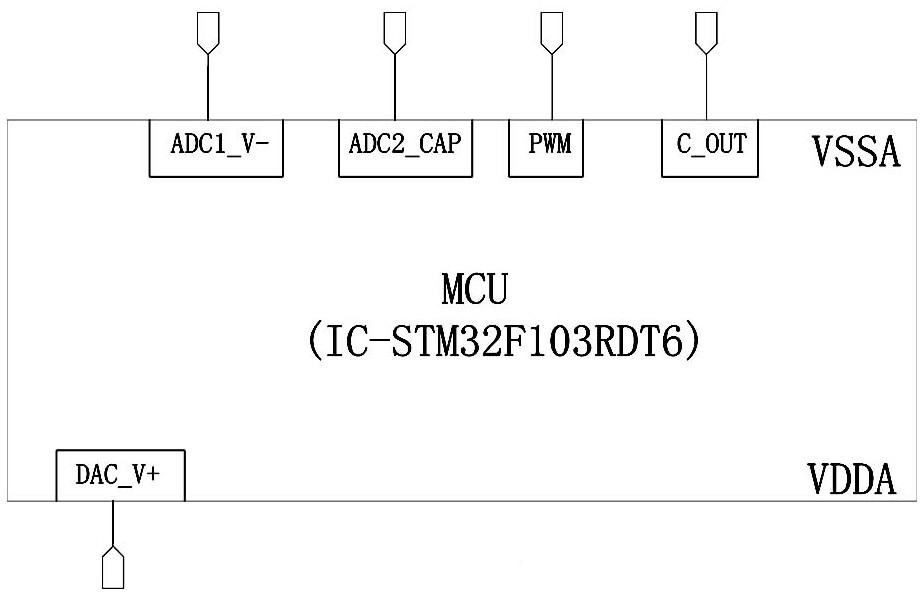

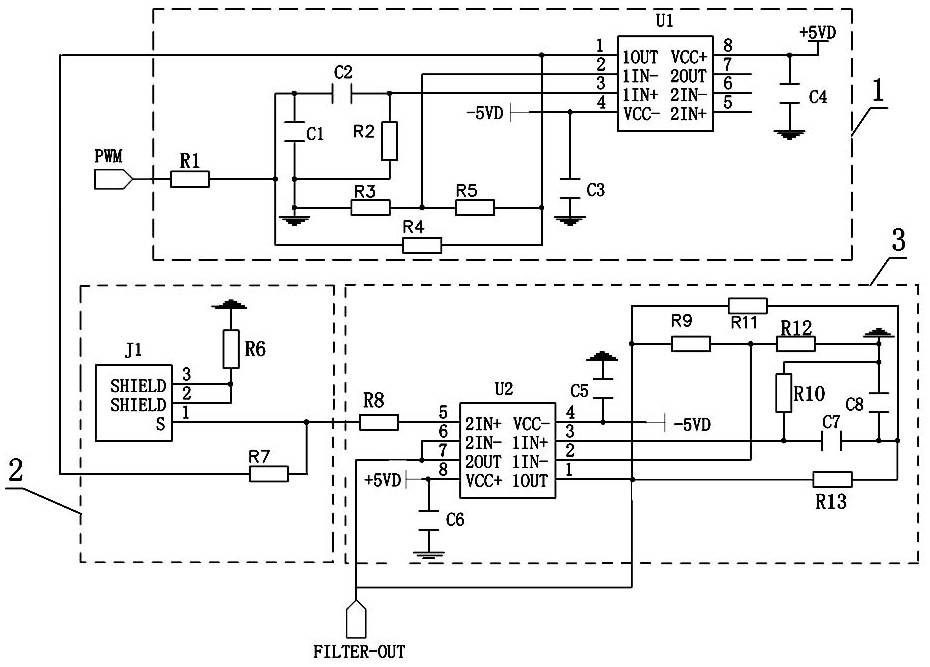

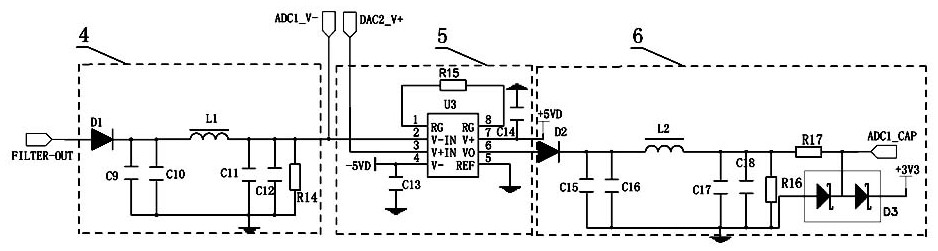

[0032] Such as Figure 1-4 As shown, the MCU-based liquid level detection circuit module of the present invention includes the following units:

[0033] The sine wave generating unit is used to receive the PWM square wave output by the MCU, and convert the PWM square wave into a sine wave signal through a band-pass filter and output it to the voltage dividing unit. The sine wave generating unit 1 includes a first operational amplifier U1, the positive input terminal (1IN+) of the first operational amplifier U1 is connected to the PWM square wave output terminal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com