Machining device

A machining and workpiece technology, which is applied in the application field of flexible mechanisms in machining, can solve the problems of difficult to achieve buffer support, increase strength, loss of space utilization, etc., and achieve the effect of strong support and strong buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]As shown in the figure: a machining device, including: a worktable 14, a first clamping hydraulic cylinder 15, a second clamping hydraulic cylinder 16, a bracket 17, a driving part 18, a working head 19, and a feed hydraulic cylinder 20; Wherein said support 17 is arranged above said workbench 14, said drive unit 18 is suspended on said support 17 top, said drive unit 18 drives said working head 19 to process workpiece 13, and said workpiece 13 left side is provided with There is a first clamping hydraulic cylinder 15, and a second clamping hydraulic cylinder 16 is provided on the right side; the feed hydraulic cylinder 20 controls the movement of the workpiece 13;

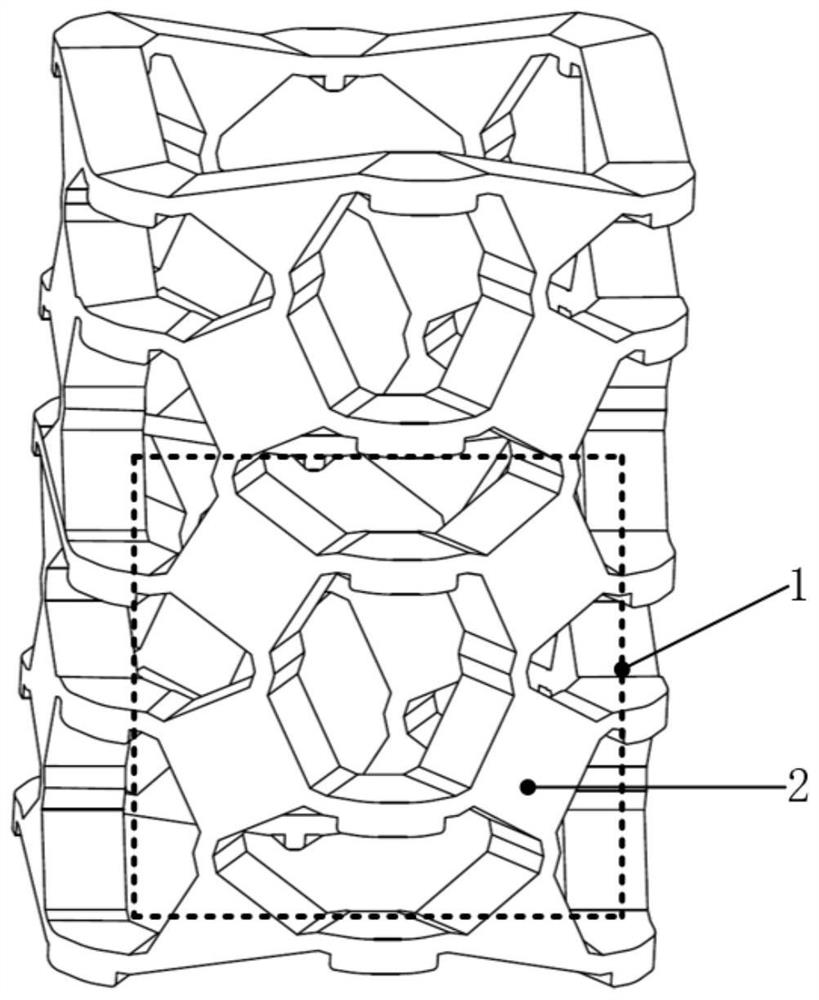

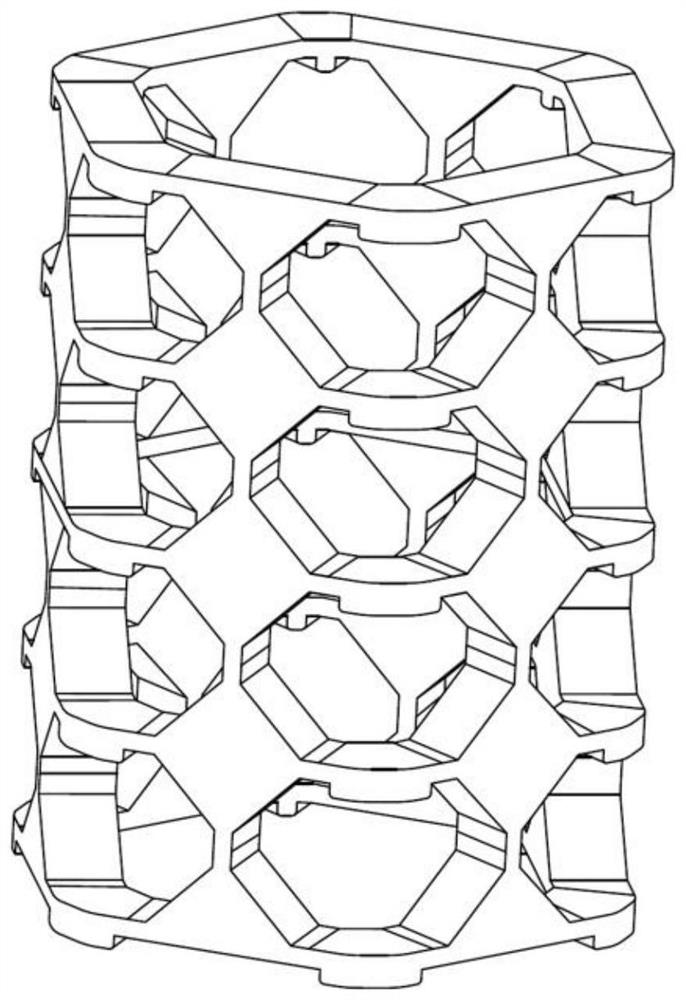

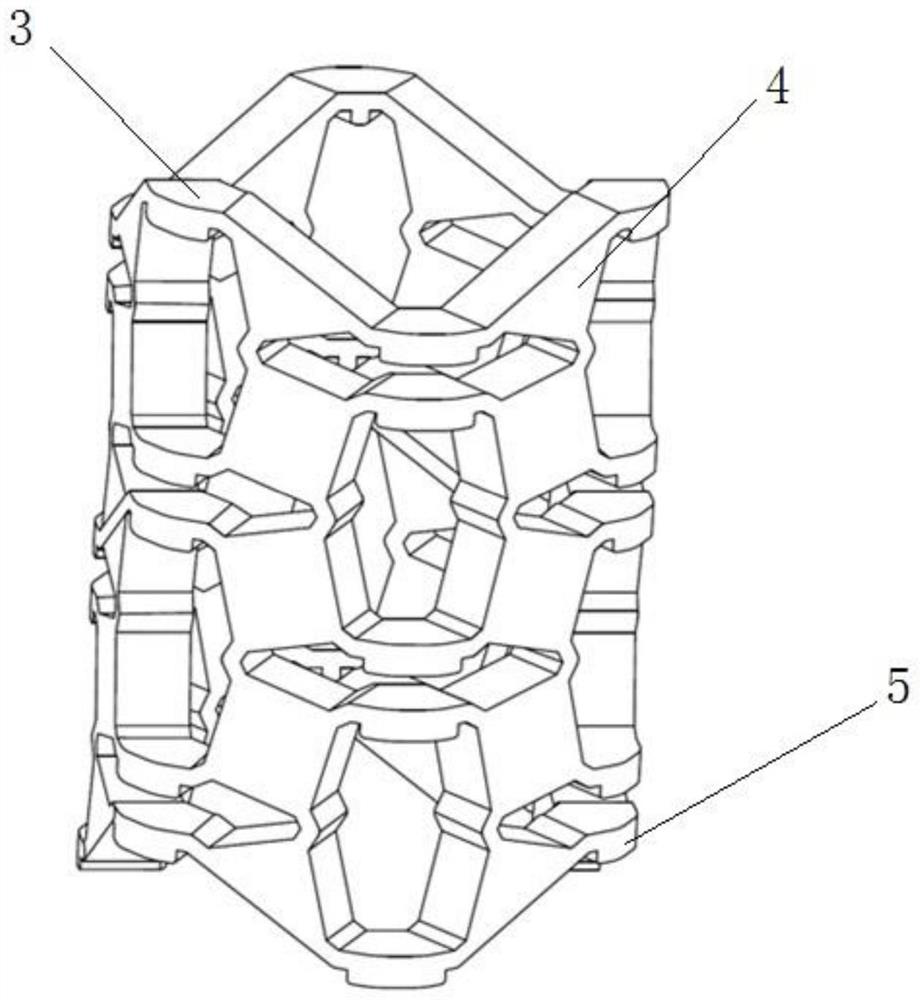

[0051] The first clamping hydraulic cylinder 15, the second clamping hydraulic cylinder 16, and the feeding hydraulic cylinder 20 all include: a cylinder body 11, a driving rod 6, a piston 7, a guide column 9, an oil port 10, a flexible Mechanism 8, connecting sleeve 12; said flexible mechanism 8 is a hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com