Iron roughneck spinning wrench lifting mechanism

The technology of a lifting mechanism and a twist tong is applied in the directions of drill pipe, drill pipe, earth-moving drilling, etc., which can solve the problems that the synchronism of the movement of the sliding blocks on both sides cannot be fully guaranteed, it is difficult to install and maintain, and the structure setting is unreasonable, etc. Achieve enhanced flexibility and smoothness, quick disassembly and maintenance, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

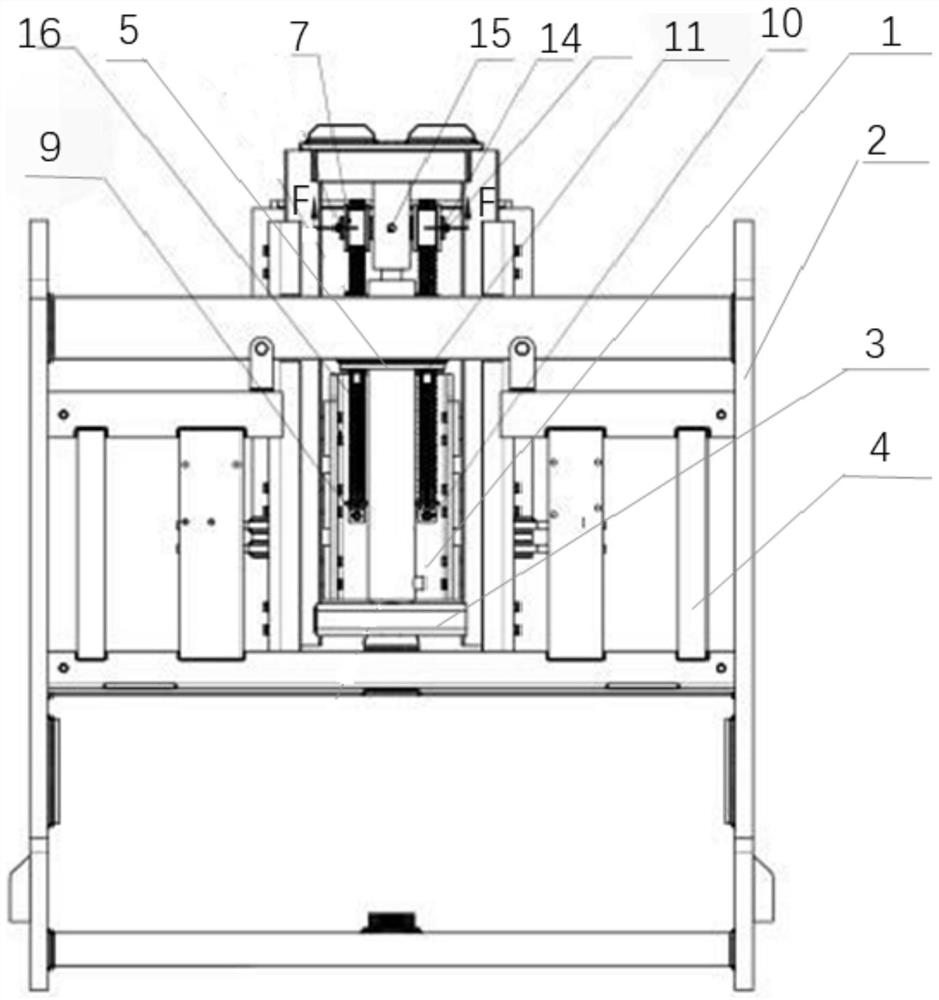

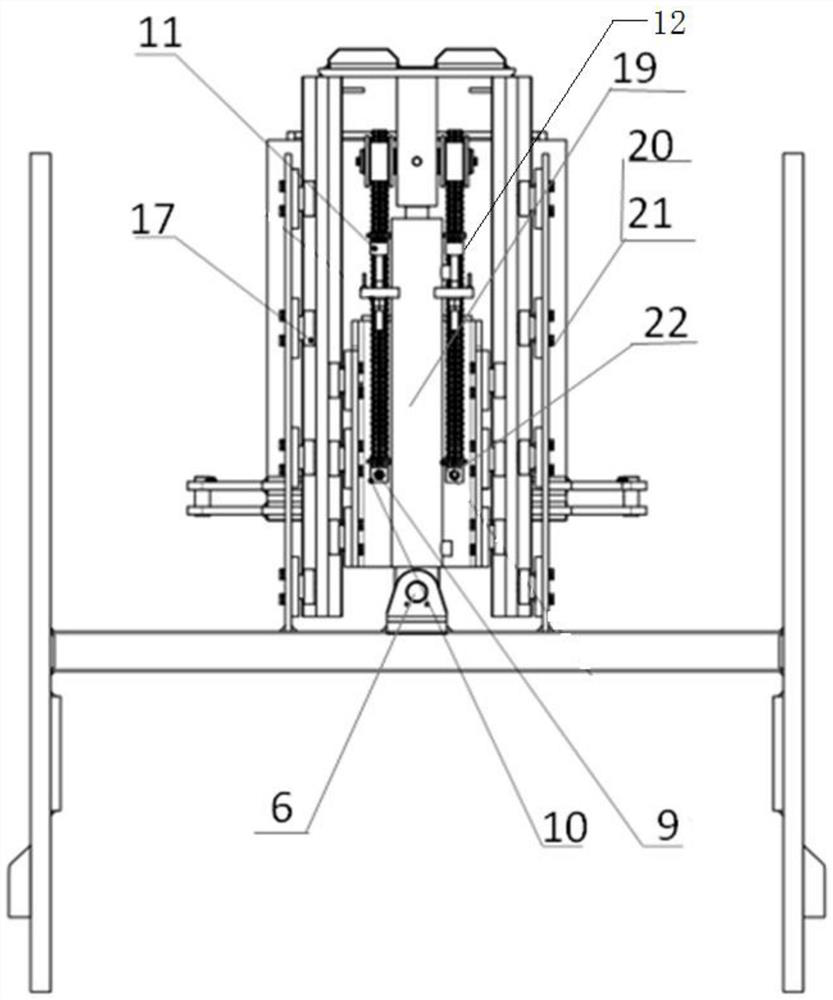

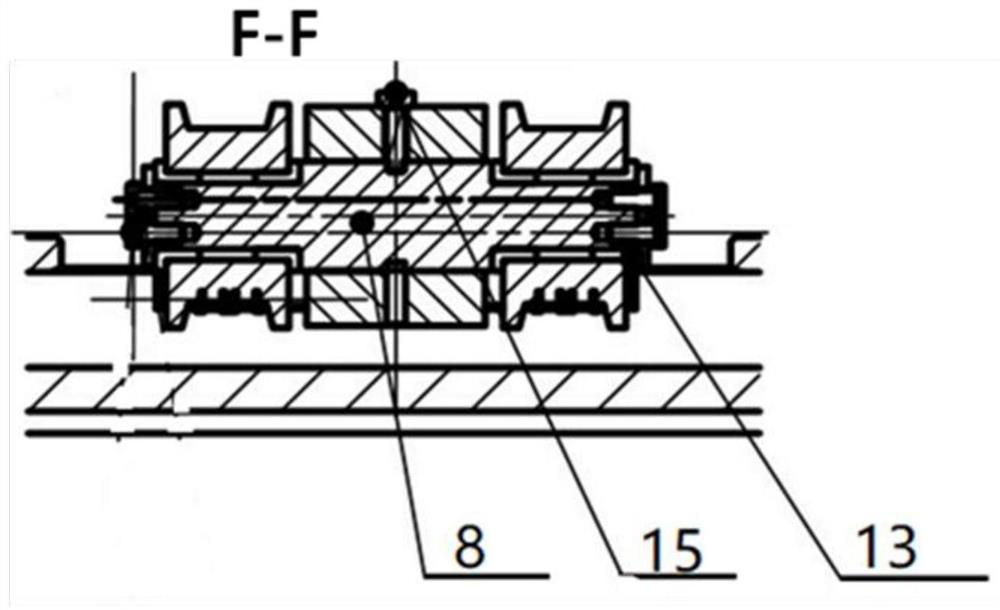

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , a lifting mechanism of iron driller spinner pliers according to the present invention, comprising a support frame assembly 1, a frame body assembly 2 and a guide body assembly 3, the support frame assembly 1 is located in the middle of the frame body assembly 2, and the spinner pliers Connected to the support frame assembly 1, between the two sides of the support frame assembly 1 and the frame body assembly 2 respectively through the vertically installed composite roller bearing group 17 and the guide body assembly 3 to realize sliding up and down, the guide body assembly 3 It is a rectangular frame, and the two guide rails in the vertical direction are I-shaped channel steel structures (such as Image 6 Shown), cooperate with two groups of compound roller bearing groups 17 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com