High-precision pan-tilt control and implementation method based on subdivision driving

A technology for subdividing drive and control methods, applied in motor generator control, control system, program control, etc., can solve the problems of the accuracy and stability of the gimbal, achieve high-precision and stable control, and improve the gimbal. The effect of precision and smoothness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

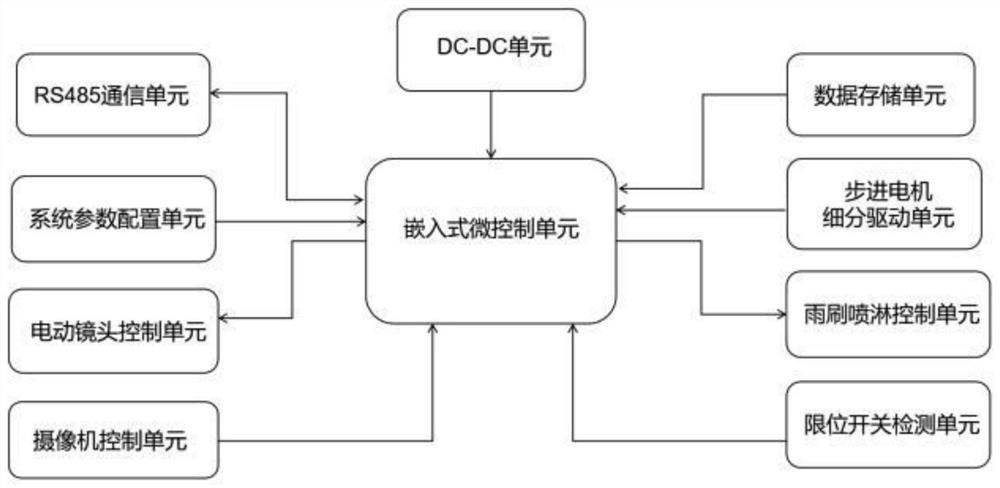

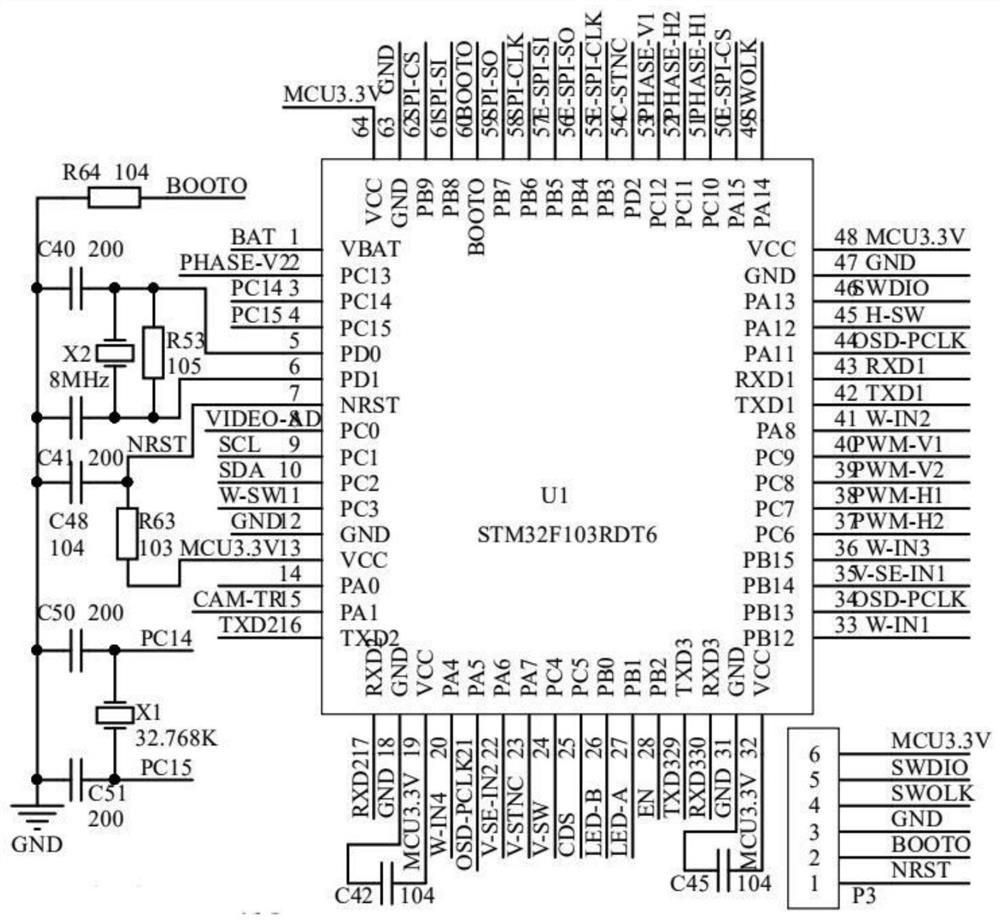

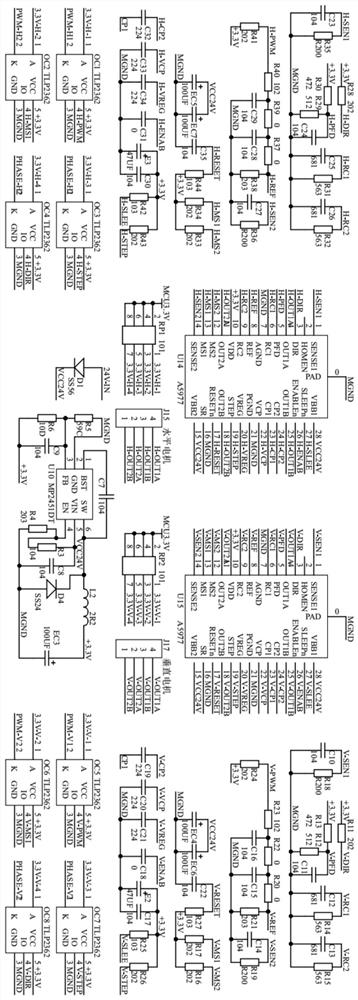

[0041] see Figure 1-14 , the present invention provides a technical solution: a high-precision pan-tilt control method based on subdivision driving, comprising the following steps:

[0042] Step 1. The DC-DC unit includes a DC-DC unit conversion circuit 1 and a DC-DC unit conversion circuit 2. The DC-DC unit converts the power required by each module and peripheral equipment according to the input power, and then controls the unit through the motorized lens. and the camera control unit are respectively externally connected with a motorized lens and a camera unit;

[0043] Step 2, configure the address and communication rate of the pan-tilt through the system param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com