High-efficiency wiring device for wire and cable processing

A technology of wire and cable and wiring device, which is applied in the field of high-efficiency wire and cable processing wiring device, can solve problems such as wire and cable falling off, and achieve the effect of avoiding falling off and improving wiring speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

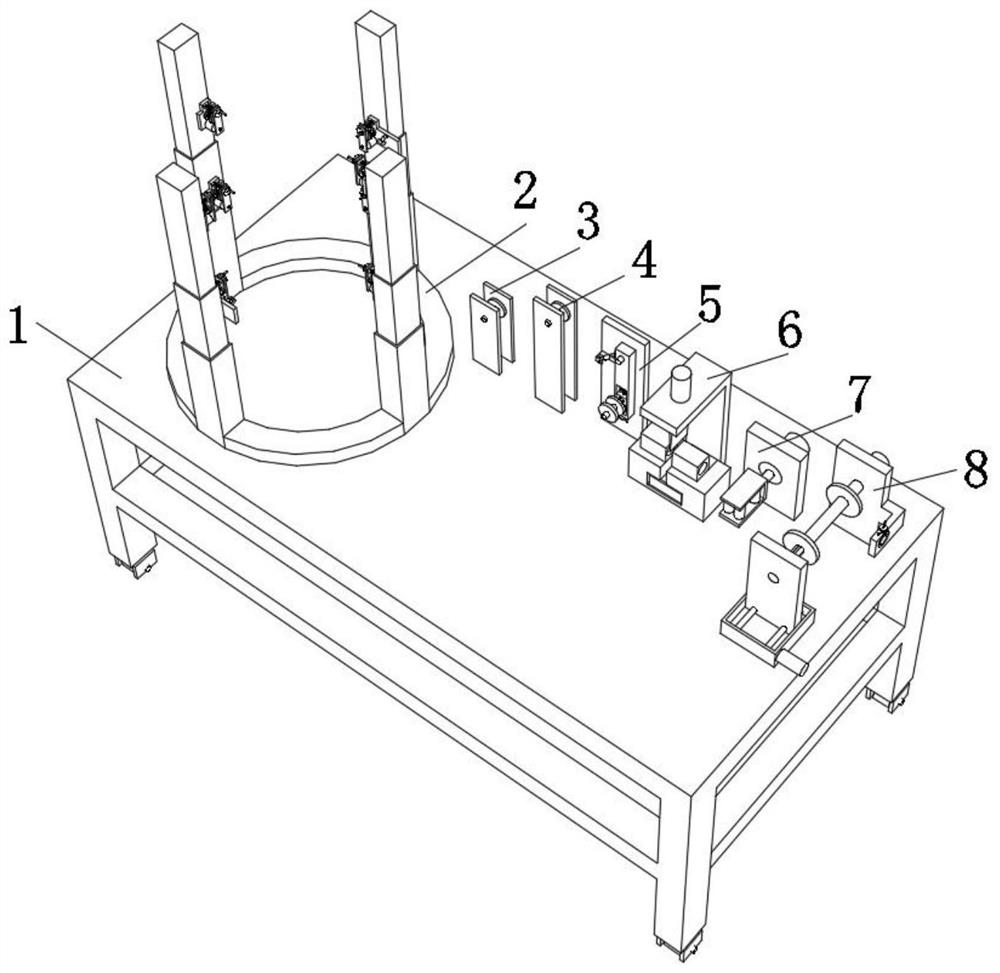

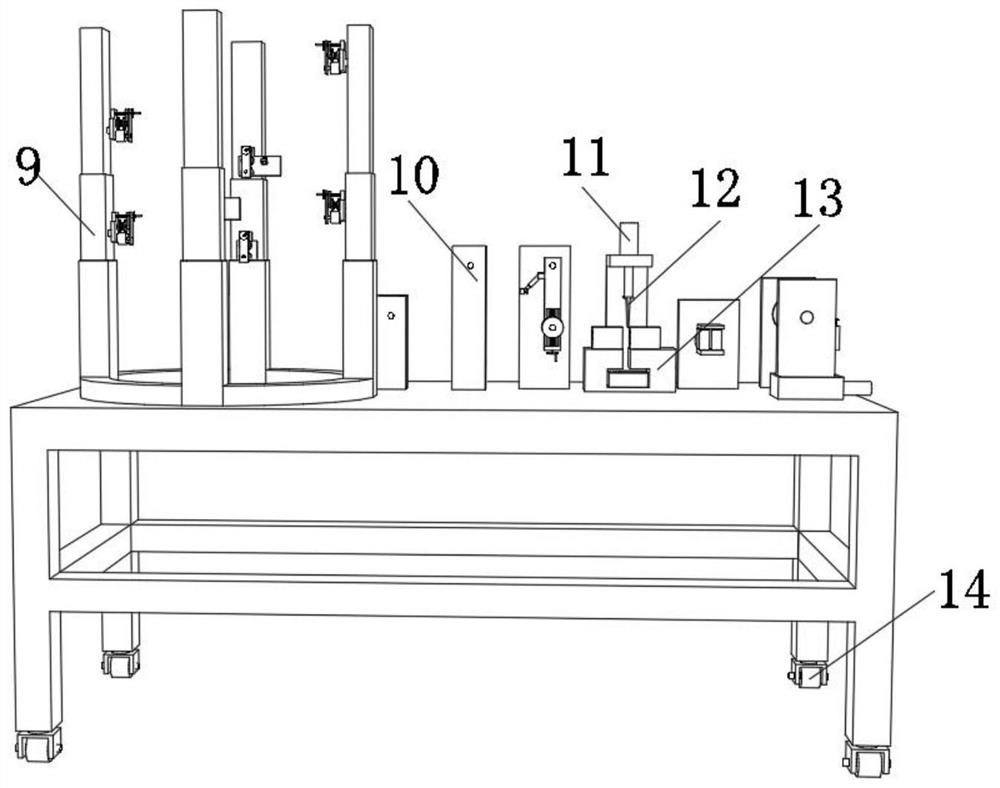

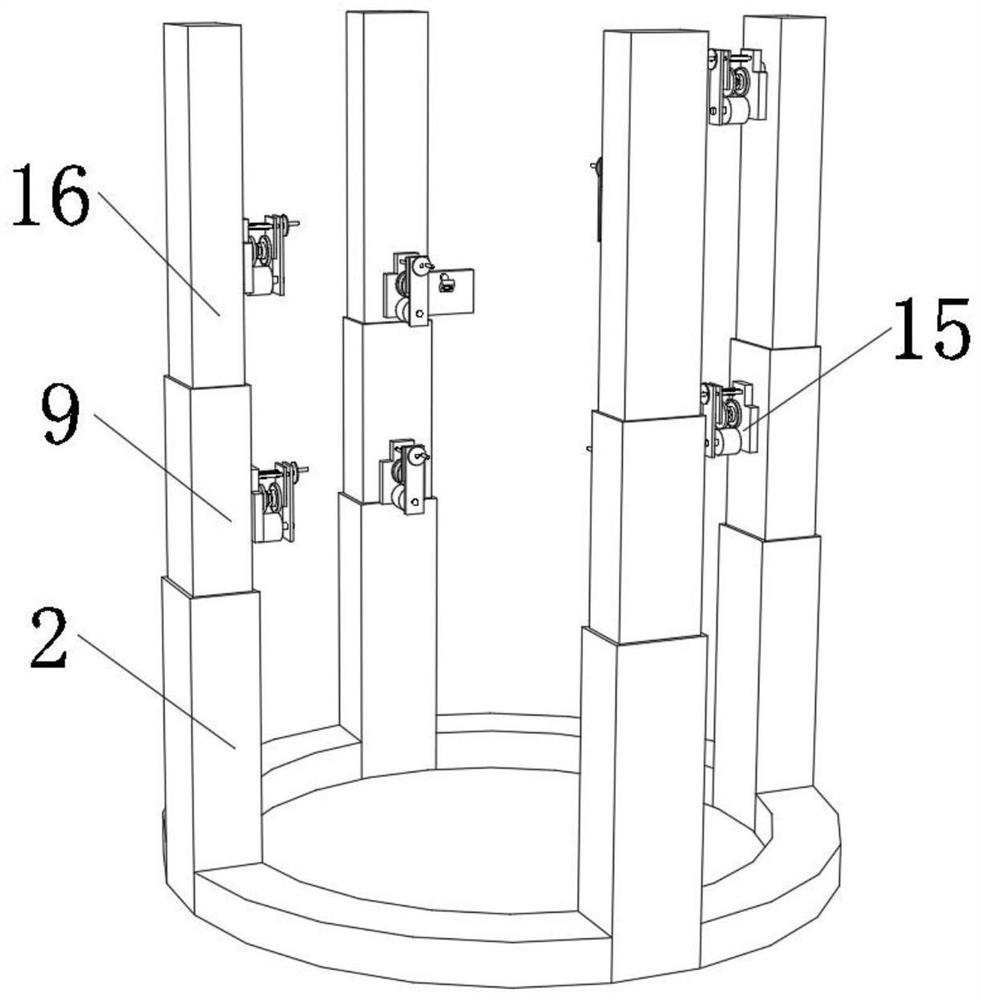

[0038] A high-efficiency routing device for wire and cable processing, such as Figure 1-4 As shown, it includes a base 1 and eight guide plates 22, the outer wall of the top of the base 1 is fixed with a cylindrical frame 2 by bolts, the inner wall of the cylindrical frame 2 is slidably connected with four first telescopic columns 9, and the four first telescopic columns 9 The inner walls of a telescopic column 9 are all slidably connected with the second telescopic column 16, and the circumferential inner walls of the four first telescopic columns 9 and the four circumferential inner walls of the second telescopic column 16 are connected with a rotating plate 15 through a damping shaft rotation. The inner walls on one side of each of the rotating plates 15 are rotatably connected with the first screw rod 17, the first accommodation roller 18 and the sponge roller 20, and the outer walls on one side of the eight rotating plates 15 are welded with two first limit posts 24. The...

Embodiment 2

[0046] A high-efficiency routing device for wire and cable processing, such as figure 1 , Figure 5 As shown, in order to make wires and cables evenly wound around the outer wall of the winding roller 32; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the top of the base 1 is fixed with a guard plate 7 by bolts, and the guard The outer wall on one side of the plate 7 has an electric push rod 27 through the height of the bolt, and the output end of the electric push rod 27 is fixed with a moving frame 25 by bolts, and the inner walls on both sides of the moving frame 25 are rotatably connected with four rotating rollers 26; Four turning rollers 26 can be used for the sliding of wires and cables, and the position of moving frame 25 can be adjusted in the horizontal direction by electric push rod 27 simultaneously, so that the process of winding wires and cables by winding rollers 32 can be The position of the wire and cable wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com