Power battery heat dissipation method

A heat dissipation method and power battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of easy overcooling, low heat removal efficiency, low performance, etc., to improve heat transfer effect and maintain efficient heat removal capability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

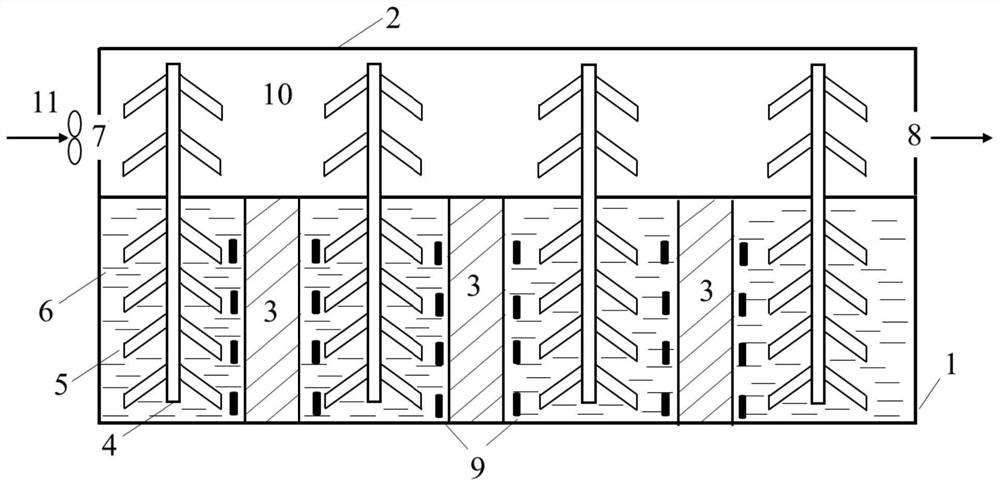

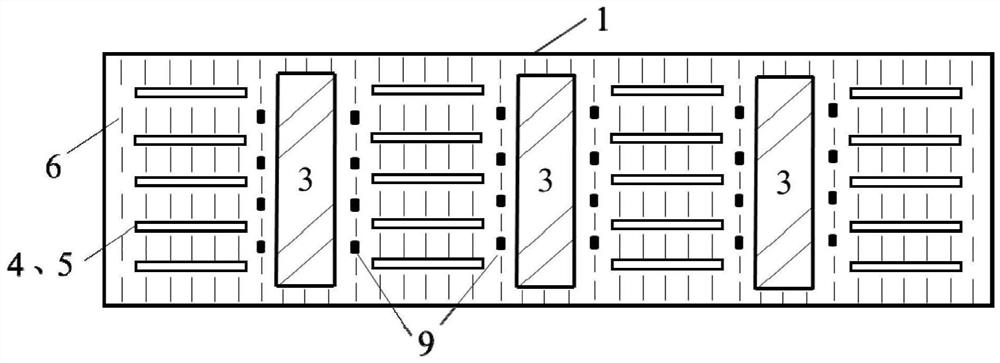

[0060] Such as Figure 1-2 As shown, the power battery cooling device of this embodiment includes a battery box 1 and an air-cooled box 2 that are attached to each other, and 20 cylindrical solid heat-conducting members 4 (heat-conducting pipes).

[0061] Wherein, the battery box 1 includes 3 groups of power batteries 3 (power battery modules) arranged at intervals in the middle and an ionic liquid phase change material 6 filling the surrounding space, and the ionic liquid phase change material 6 is used to absorb the heat generated by the power battery 3 , the ionic liquid phase change material 6 used is 1-methyl-3-hexadecyl imidazolium bromide and 1,2-dimethyl-3-hexadecyl imidazolium bromide with a molar ratio of 1:0.5, And it is doped with porous material with a volume fraction of 28% (porosity is 93%, particle size is 2mm).

[0062] The inside of the air-cooled box 2 can circulate cooling air for deriving the heat in the air-cooled box 2. The lower part of the left side i...

Embodiment 2-7

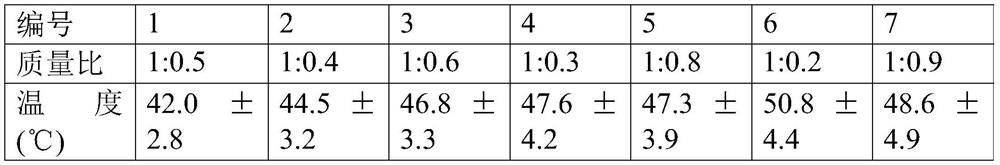

[0067] Using the device and method in Example 1, the only difference is that the mass ratio of 1-methyl-3-hexadecyl imidazolium bromide and 1,2-dimethyl-3-hexadecyl imidazolium bromide is as follows Table 1. The temperature measured by the temperature sensor 9 is shown in Table 1.

[0068] Table 1

[0069]

[0070] As shown in Table 1, using the power battery heat dissipation method of the present invention can ensure efficient heat dissipation and stable and uniform temperature of the power battery 3 .

Embodiment 8

[0072] Using the apparatus and method in Example 1, the only difference is that only 1-methyl-3-hexadecyl imidazolium bromide is used. The average temperature measured by the temperature sensor 9 is 47.2±4.0° C., which can ensure efficient heat dissipation and stable and uniform temperature of the power battery 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Heat of phase change | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com