Welding wire for welding turbine shell waste discharge valve, welding process and welding tool

A welding process and welding tooling technology, used in welding media, welding accessories, welding equipment, etc., can solve problems such as shrinkage, welding hot cracks, and lack of penetration between layers, and achieve short time required and no cracks in welding quality. , The effect of good internal welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

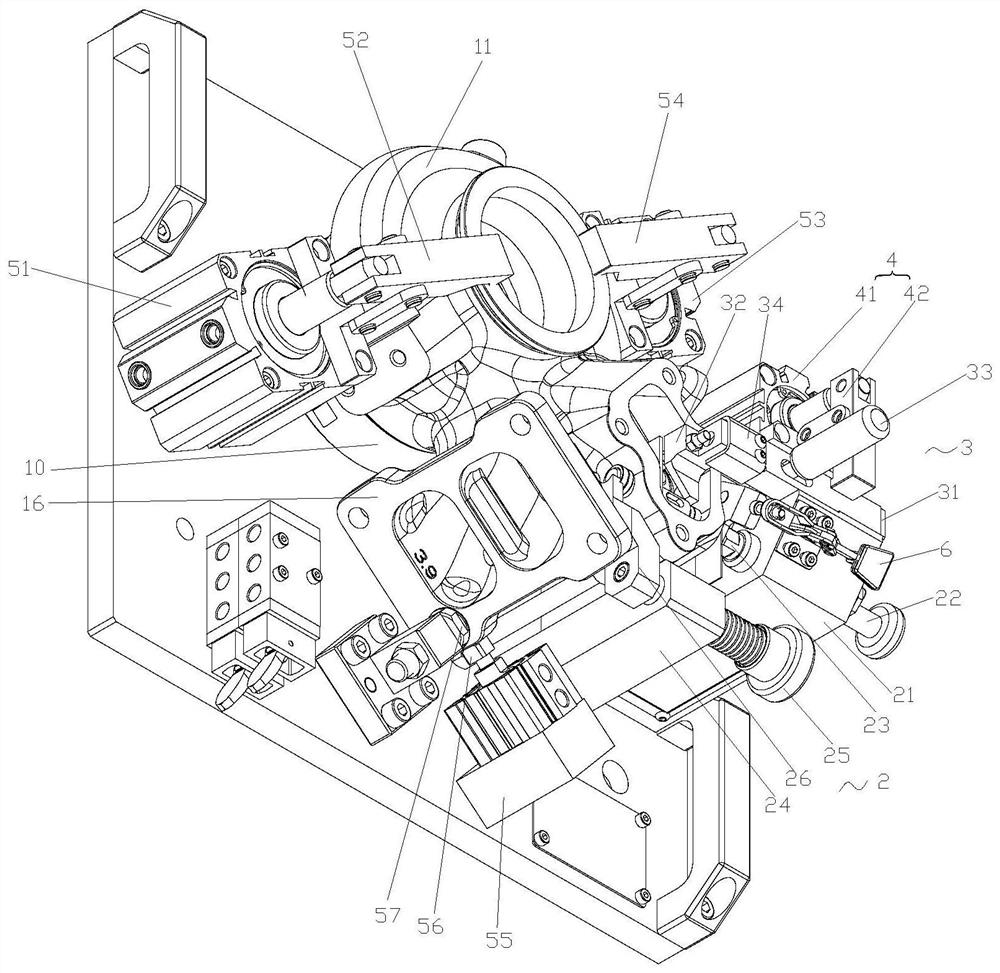

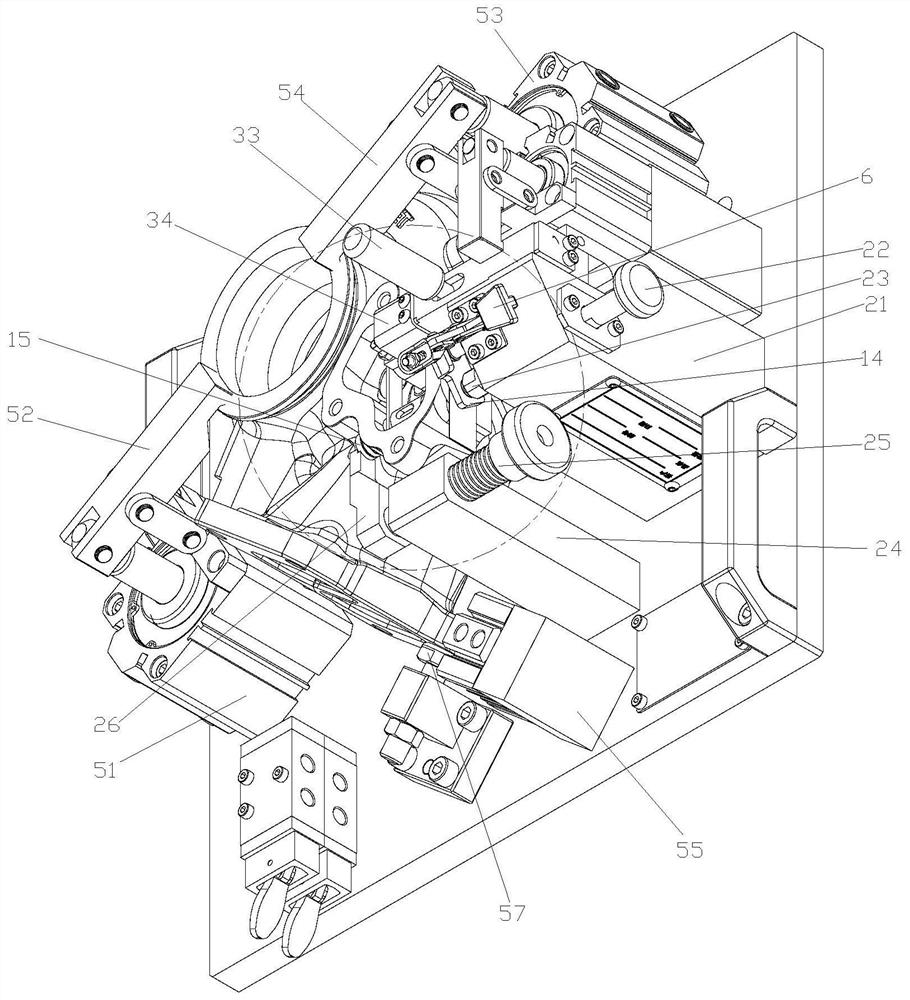

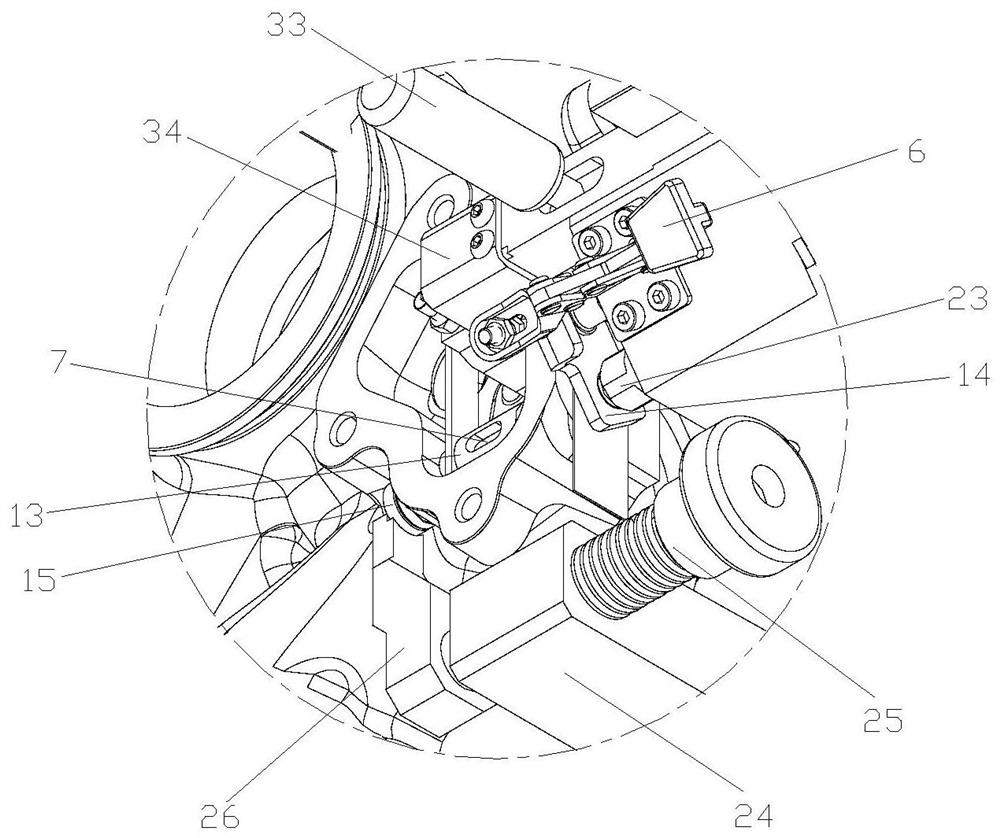

Image

Examples

Embodiment 1

[0091] In the preferred embodiment provided by the present invention, the composition and weight percentage of the welding wire (abbreviated as the first welding wire) for welding the exhaust valve of the turbine casing are:

[0092] C: 0-0.22%;

[0093] Mn: 0-0.1%;

[0094] Fe: 0-9.7%;

[0095] P: 0-0.003%;

[0096] S: 0-0.002%;

[0097] Si: 0-0.2%;

[0098] Ti: 0-0.11%;

[0099] Cr: 18-24.6%;

[0100] AL: 0-2.15%;

[0101] Zr: 0-0.05%;

[0102] The remainder is Ni.

Embodiment 2

[0104] In another embodiment provided by the present invention, the composition and weight percentage of the welding wire (second welding wire for short) used for welding the exhaust valve of the turbine casing are:

[0105] C: 0-0.05%;

[0106] Mn: 2.5-3.5%;

[0107] Fe: 0-1.5%;

[0108] P: 0-0.01%;

[0109] S: 0-0.010%;

[0110] Si: 0-0.25%;

[0111] Cu: 0-0.5%;

[0112] Ti: 0-0.75%;

[0113] Cr: 18-22%;

[0114] Nb and Ta: 2.0-3.0%;

[0115] The remainder is Ni.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com