Long-line platform prefabricated part production line maintenance system

A prefabricated component and maintenance system technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to realize single maintenance of single mold table, uneven cooling and heating of pipeline mold table, simultaneous heating and maintenance, etc., to achieve independent maintenance , to avoid the shutdown of the whole line, and to avoid the effect of pipeline pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

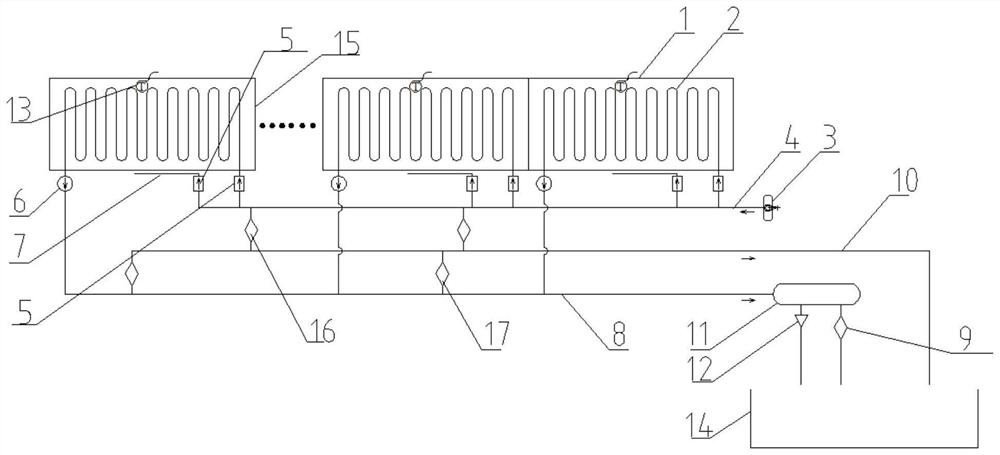

[0021] figure 1 It is a structural schematic diagram of the maintenance system of a long-line table prefabricated component production line of the present invention. The single-mode table 1 is fixed on the ground foundation, and there is an insulation layer 15 on the lower side of the single-mode table 1. The maintenance pipeline 2 is placed between the single-mode table 1 and the insulation layer. Between 15. A plurality of single mold tables 1 are connected end to end to form a long-line mold table. The maintenance pipeline 2 supplies heat for the single-mode table 1 . The lower right corner of maintenance pipeline 2 is the steam inlet, and the lower left corner is the steam outlet. The steam source 3 provides high-temperature steam for the maintenance system, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com