Crystal pulling method, single crystal furnace and computer readable storage medium

A technology for pulling single crystals and single crystals, applied in the field of solar photovoltaic, can solve problems such as unfavorable long-term crystal pulling, crucible deformation, difficulty in ensuring yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

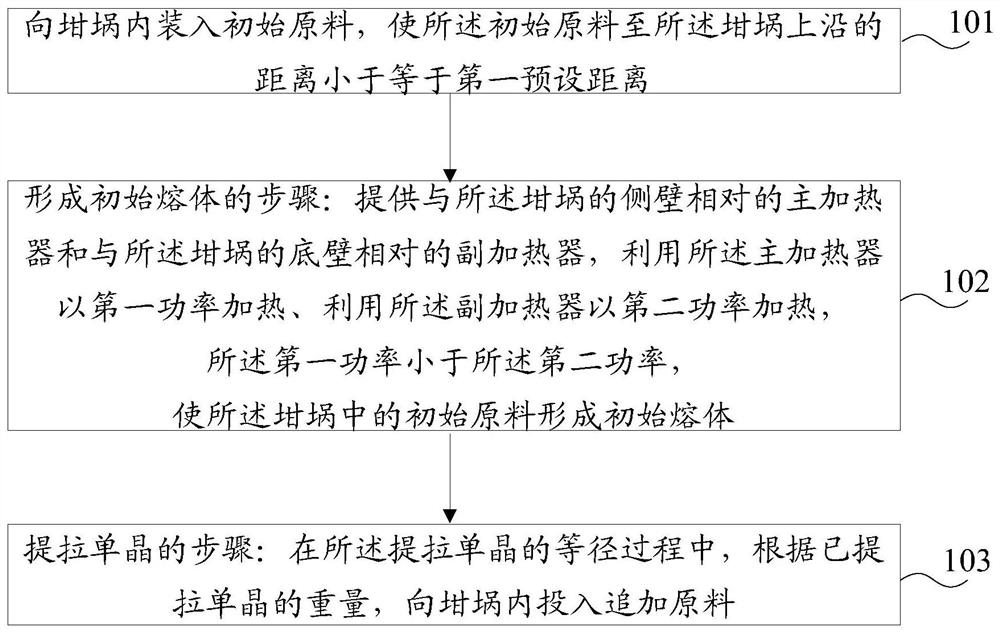

[0044] refer to figure 1 , which shows a flow chart of a crystal pulling method in Embodiment 1 of the present invention, which may specifically include the following steps:

[0045] Step 101, loading initial raw materials into the crucible so that the distance from the initial raw materials to the upper edge of the crucible is less than or equal to a first preset distance.

[0046] In the embodiment of the present invention, the initial raw material may be a raw polycrystalline raw material, etc., which is not specifically limited in the embodiment of the present invention.

[0047] In the embodiment of the present invention, the first preset distance may be set according to actual needs, and in the embodiment of the present invention, it is not specifically limited.

[0048]In the embodiment of the present invention, the crucible may be filled with initial raw materials manually or by a mechanical arm, so that the distance from the initial raw materials to the upper edge of...

Embodiment 2

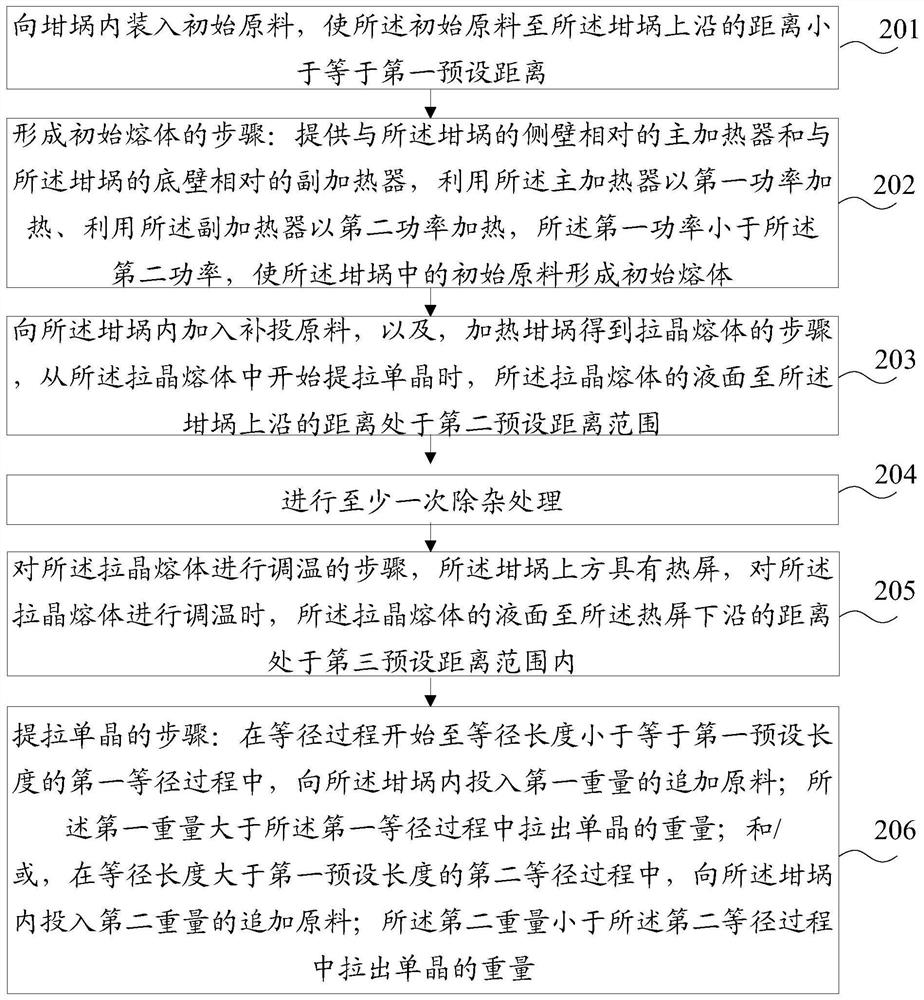

[0071] refer to image 3 , image 3 A flowchart of a crystal pulling method according to Embodiment 2 of the present invention is shown, which may specifically include the following steps:

[0072] Step 201, loading initial raw materials into the crucible so that the distance from the initial raw materials to the upper edge of the crucible is less than or equal to a first preset distance.

[0073] Step 202, the step of forming an initial melt: providing a main heater opposite to the side wall of the crucible and an auxiliary heater opposite to the bottom wall of the crucible, using the main heater to heat at a first power, using The auxiliary heater is heated with a second power, and the first power is lower than the second power, so that the initial raw material in the crucible forms an initial melt.

[0074] In the embodiment of the present invention, step 201 and step 202 may refer to the above step 101 and step 102 respectively, and in order to avoid repetition, details ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com