Fabricated self-resetting beam column joint and construction method thereof

A beam-column joint and self-resetting technology, which is applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of increasing structural acceleration response, stress relaxation of prestressed tendons, weak energy dissipation characteristics, etc., and achieve improved Self-resetting ability, overall rigidity guarantee, and the effect of improving brittle failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

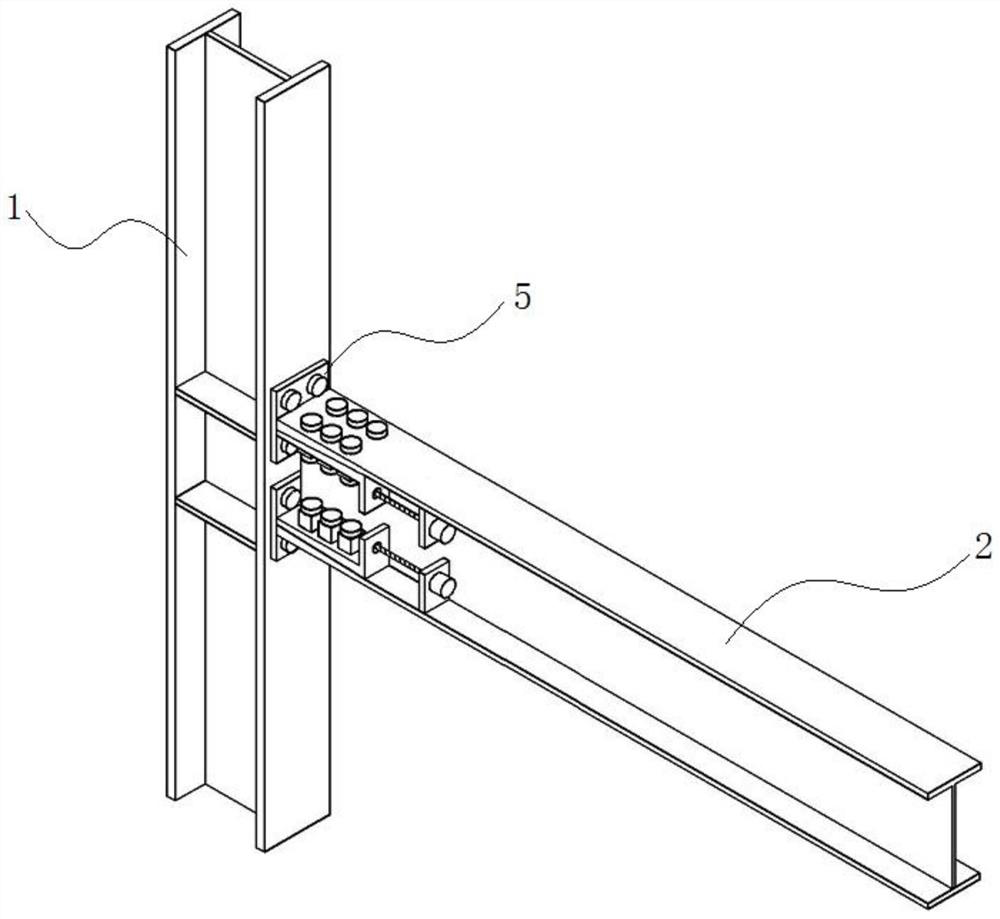

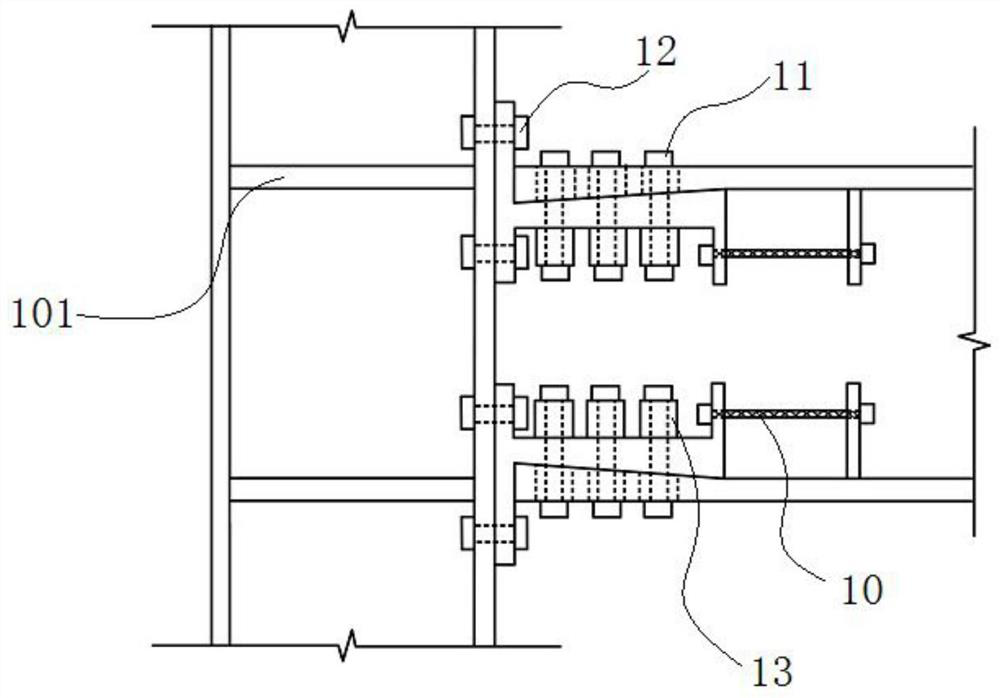

[0032] see figure 1 with figure 2 , this embodiment discloses an assembled self-resetting beam-column node, including a column 1 , an I-shaped steel beam 2 , a connector 5 , an SMA cable 10 and an SMA bolt 11 .

[0033] The column 1 is an I-shaped steel column. A stiffener 101 is welded at the web of the column 1 .

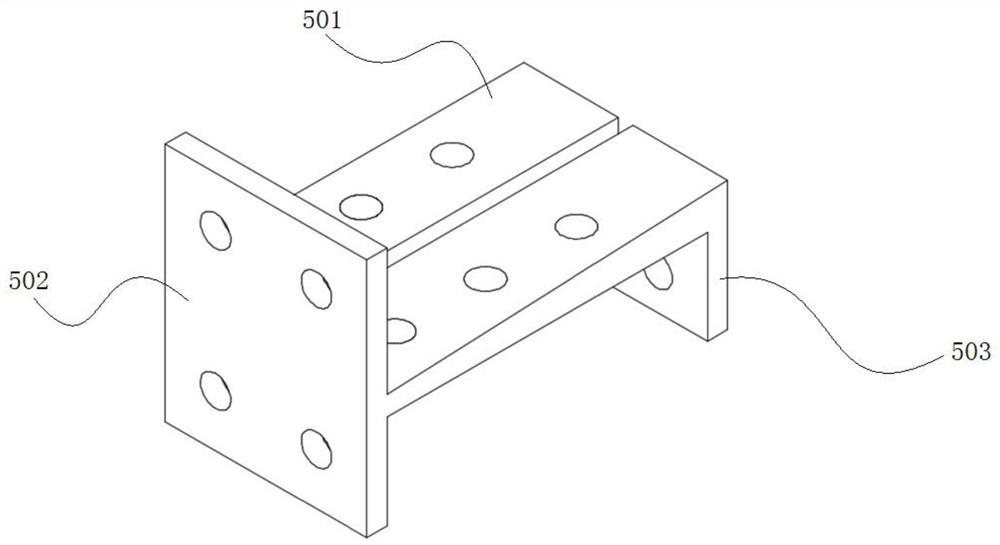

[0034] see image 3 with Figure 4 , the connecting member 5 includes a riser 502 and an L-shaped plate arranged on one side of the riser 502 . The long limb of the L-shaped plate is a wedge-shaped plate 501 , and the short limb is an outwardly extending flange 503 . The surface of the wedge plate 501 includes a straight surface and a wedge surface. A wedge angle is formed between the straight surface and the wedge-shaped surface. The additional overhanging flange 503 is a straight plate. Said additional overhanging flange 503 is arranged parallel to the riser 502 . The additional overhanging flange 503 is arranged on one side of the straight surface of ...

Embodiment 2

[0042] This embodiment discloses a construction method for the assembled self-resetting beam-column joint described in Embodiment 1, which includes the following steps:

[0043] 1) Standardized production of columns 1, I-shaped steel beams 2, connectors 5, SMA cables 10 and SMA bolts 11 in the factory. Waist-shaped bolt holes are provided at the ends of the I-shaped steel beam 2 flanges. An additional connecting plate 204 is welded on the lower surface of the upper flange 202 of the I-shaped steel beam 2 and the upper surface of the lower flange 203 .

[0044] 2) Screw the screw rod of SMA bolt 11 through the waist bolt hole of the flange of I-shaped steel beam 2 and the circular bolt hole of corresponding wedge plate 501 and then screw into the steel spacer 13, and connect the I-shaped steel beam 2 and the wedge Part 5 is connected and compressed.

[0045] 3) Use the SMA cable 10 to connect the additional overhanging flange plate 503 with the additional connecting plate 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com