Complete device and method for filling coal-based solid waste paste-like body on large-dip-angle fully mechanized coal mining face

A complete set of equipment, paste-like technology, applied in the fields of backfill, safety device, mining equipment, etc., can solve the problems of low backfill efficiency, low backfill body strength, and low utilization rate of tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

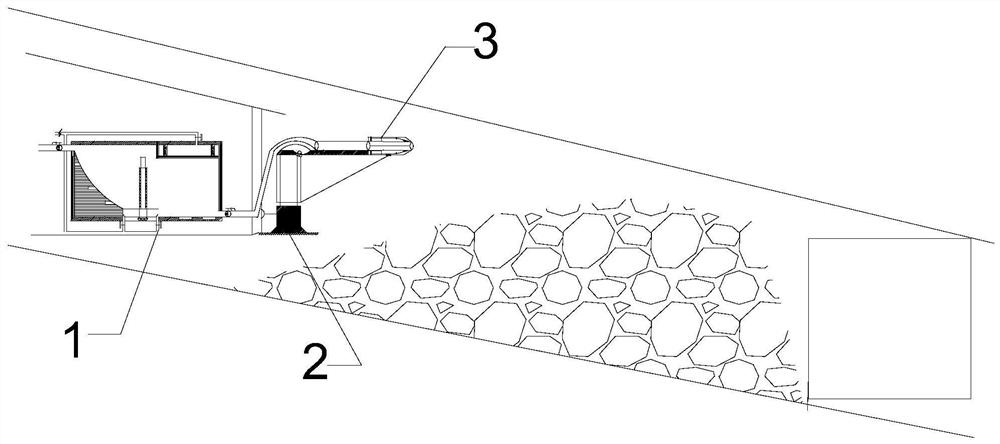

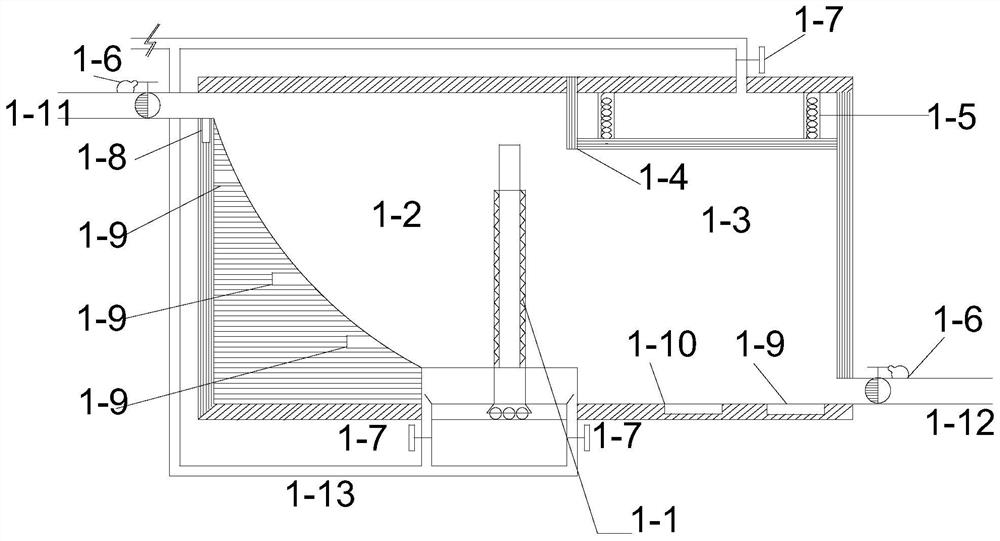

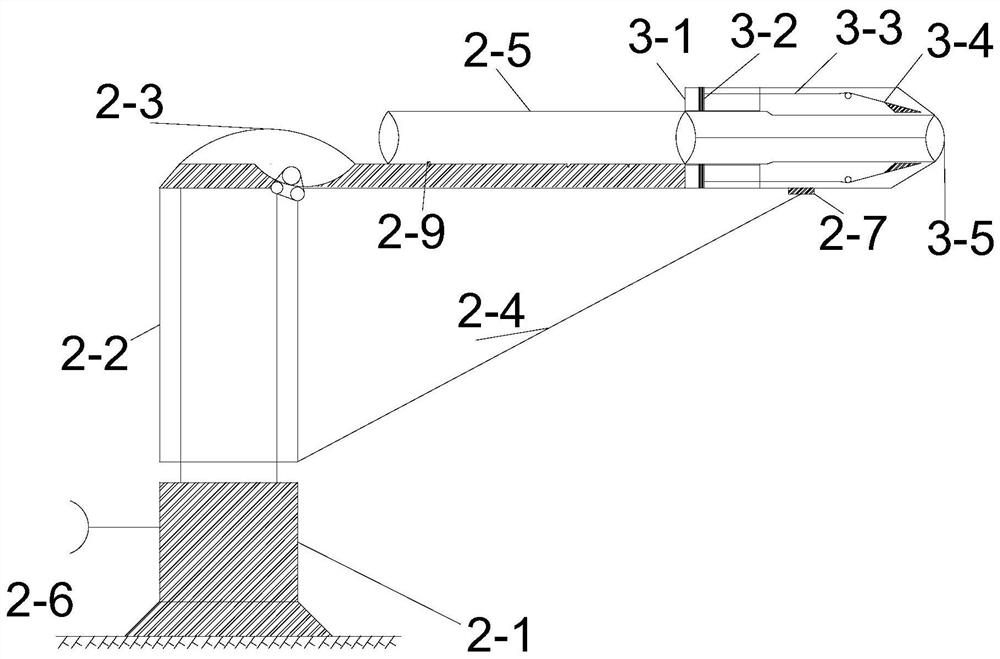

[0017] Please refer to Figure 1~3 , the invention discloses a complete set of equipment and method for filling coal-based solid waste like paste in a fully mechanized mining face with a large inclination angle, including a centralized pressurized conveying box for paste (1), a conveying column with a large inclination angle (2) and a wind force deformation device for the nozzle ( 3) Composition, when starting to work, the paste enters the paste input box (1-2). When the paste height in the input box reaches the position of the capacity sensor (1-9), the sensor is triggered and the isolation plate (1-1) rises , then close the flow valve on the left side of the input box, turn the cam (1-6), and the isolation plate (1-1) descends to transfer the similar paste to the paste pressurization box (1-3), start the pressurization program of the pressurization box, The pressure plate (1-4) on the upper part of the pressurized box is pushed downward by the wind to do work. After reaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com