Electric push rod with hand-rotating release device

A release device, electric push rod technology, applied in the direction of electromechanical devices, electric components, transmission devices, etc., can solve the problems of limited installation stroke, complicated operation, difficult to control the pulling force or stroke, etc., to achieve convenient operation and smoothness. Good, reduce the effect of momentary oversize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

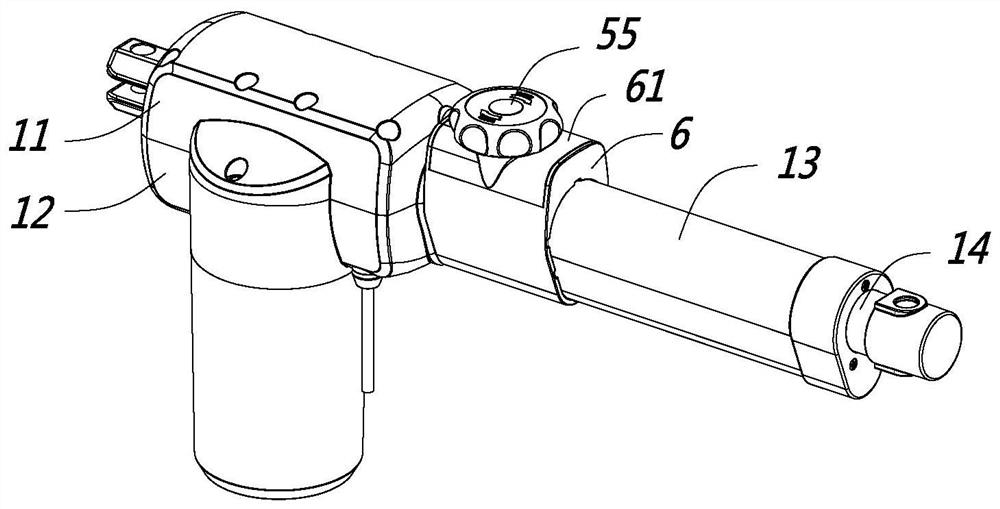

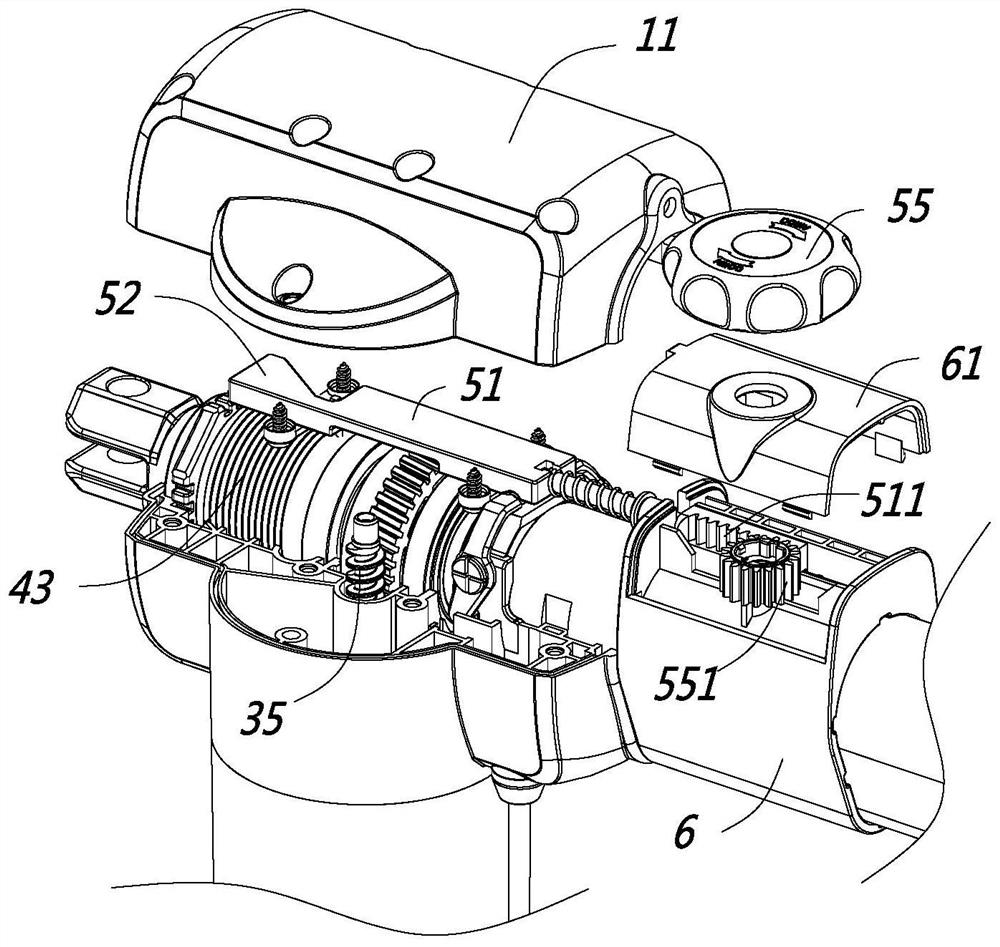

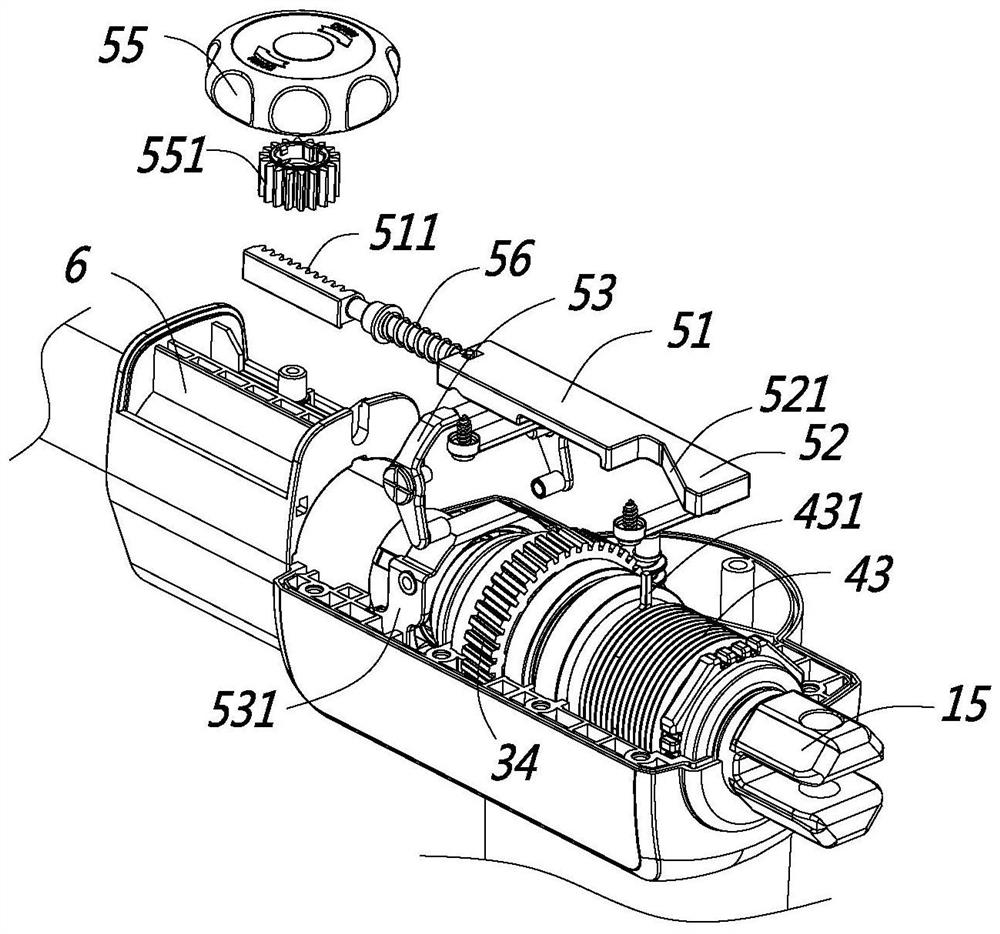

[0039] like Figure 1 to Figure 5 As shown, this embodiment is an electric push rod. The electric push rod is also commonly called a linear drive or a linear actuator. The electric push rod includes a casing, an outer tube 13, an inner tube 14, a drive motor, a transmission assembly, and a rotating screw. 20 and a transmission nut 21, the drive motor drives the rotating screw 20 to rotate through the transmission assembly, the rotating screw 20 rotates and drives the transmission nut 21 to move axially along the rotating screw 20, the transmission nut 21 is fixedly connected with the inner tube 14, and the transmission nut 21 When moving axially, the inner tube 14 is driven to move axially relative to the outer tube 13 and the outer shell, and the outer end of the inner tube 14 is connected to the object to be driven. The electric push rod in this embodiment also includes:

[0040]The clutch device is arranged between the transmission assembly and the rotating screw 20, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com