Skid-mounted one-island-four-skid LNG loading and unloading vehicle

A technology of loading and unloading trucks and four corners, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc. and other problems to achieve the effect of shortening installation and debugging time, reducing construction and debugging personnel, and facilitating construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

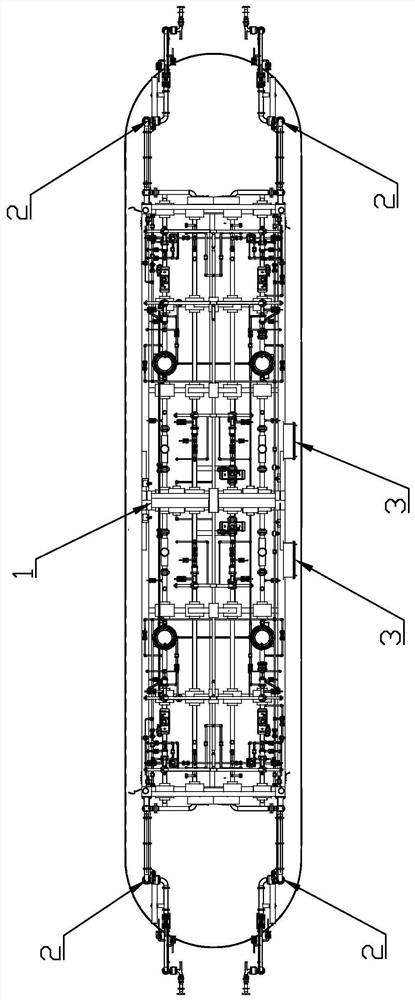

[0032] In the present invention, the process pipelines (including liquid phase pipelines, gas phase pipelines, liquid collection pipelines, vent pipelines, nitrogen pipelines, instrument air pipelines, etc.) in the traditional four tank car skids, on-site control panels, electrostatic grounding systems, pipeline supports and Cooling materials, etc. are combined, optimized and integrated, and arranged in an island to form the "one island with four skids" loading and unloading truck technology, which can simultaneously load and unload four LNG tank trucks.

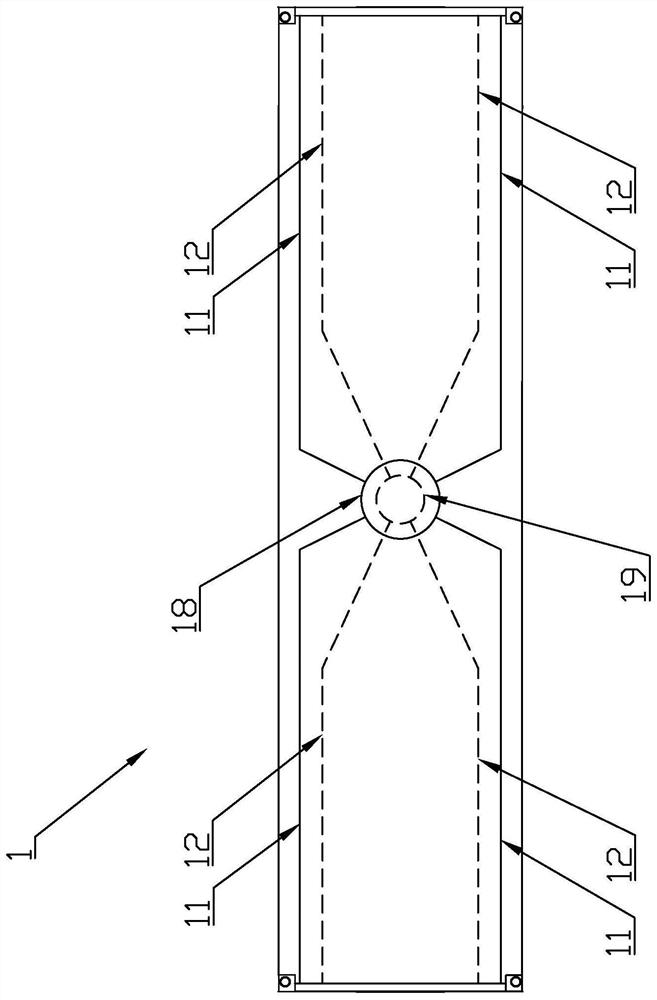

[0033] Such as figure 1 As shown, the present invention is composed of the "one island and four skids" tank car loading skid system, and through the consideration of installation functionality, skid installation and independence, the "one island and four skids" tank car loading skid system is divided into seven Modules; they are: main body module 1, four low-temperature crane tube modules 2 and two local control cabinet modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com