Compound type compact heat exchanger core

A compact, heat exchanger technology, applied in heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as fluid medium blockage, reduce flow resistance, increase heat exchange effect, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

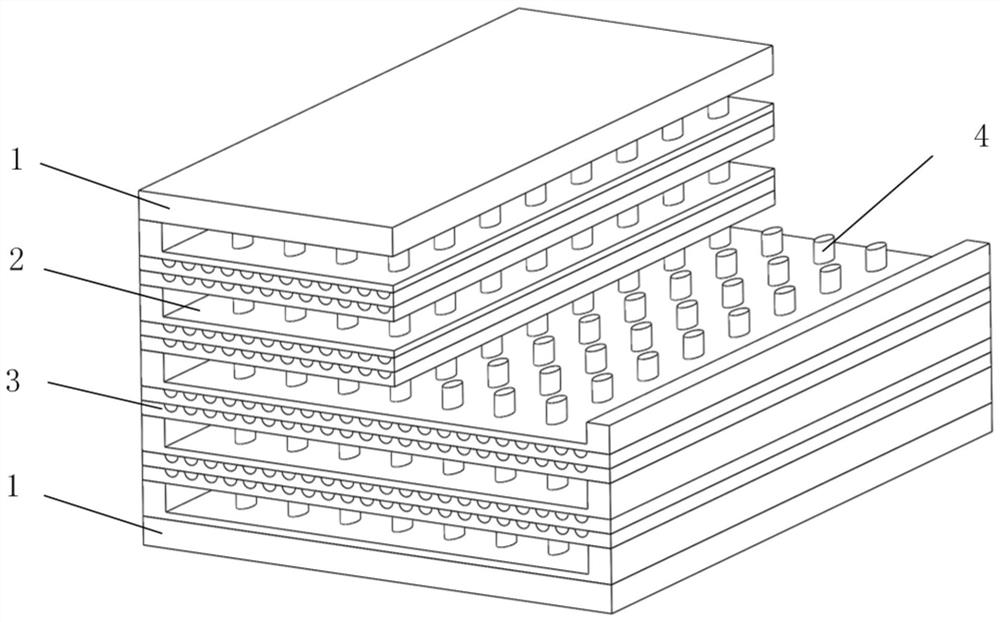

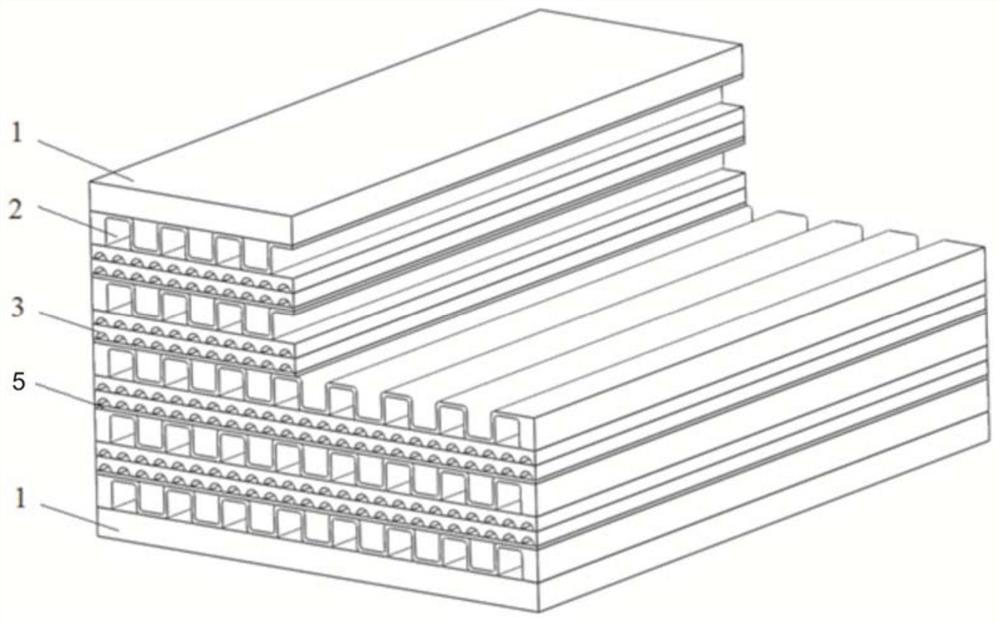

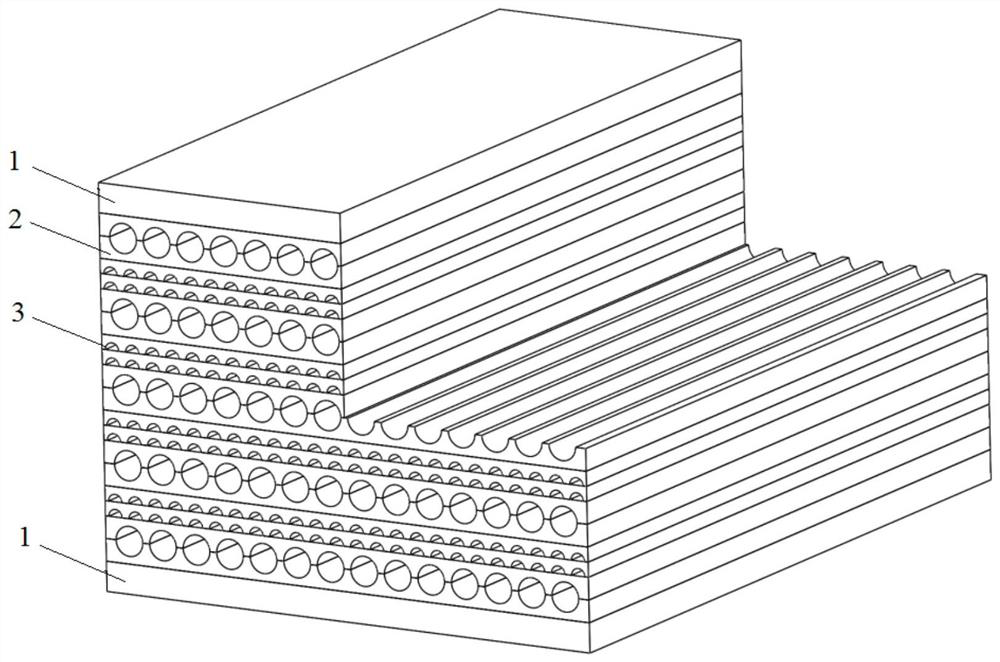

[0031] The invention discloses a composite compact heat exchanger core body, comprising an end plate 1, a gas heat exchange unit 3 and a liquid heat exchange unit 2; the gas heat exchange unit 3 and the liquid heat exchange unit 2 are stacked alternately Between the end plates 1 ; the flow channel of the liquid heat exchange unit 2 is larger than the heat exchange channel of the gas heat exchange unit 3 . The height of the flow channel of the liquid heat exchange unit 2 can be adjusted according to the physical properties of hot and cold fluids and the requirements of working conditions.

[0032] The flow channel of the liquid heat exchange unit 2 is provided with fins 4 which can improve the structural strength.

[0033] An example of the present invention is figure 1 As shown, the fins are multiple airfoils ( Figure 4a shown in ) or Type S ( F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com