Relay packaging inspection tool

A relay and tooling technology, applied in the field of relay packaging and inspection tooling, can solve problems such as low test accuracy and efficiency, automatic analysis and processing, and damage to relay products, and achieve the effects of improving inspection automation, saving money, and reducing purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

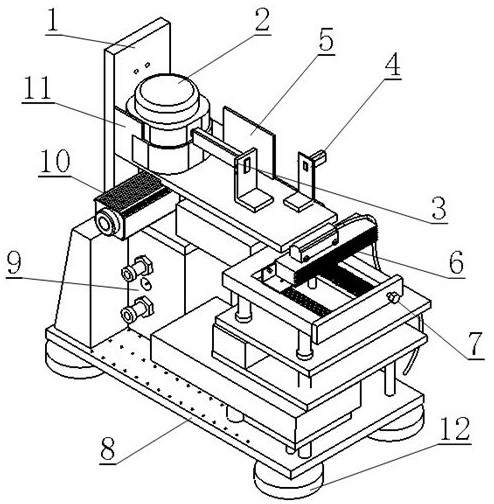

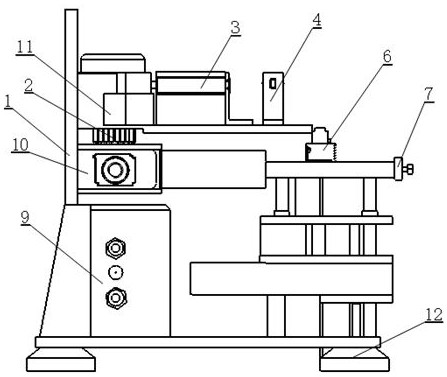

[0030] Such as Figure 1-7 As shown, the present embodiment provides a relay package inspection tool, comprising: the bracket 1 is divided into upper and lower parts, the upper half is plate-shaped, the lower half is wedge-shaped, the bracket 1 is perpendicular to the surface of the inspection platform; the upper part of the base 8 The surface is connected to the lower half of the support 1, the base 8 is perpendicular to the support 1, the lower surface of the base 8 is fixedly installed with an anti-skid foot pad 12, and the anti-skid foot pad 12 is placed at the corner of the lower surface of the base 8, and the anti-skid foot pad 12 is The suction cup is attached to the surface of the inspection platform; the relay fixture 11 protrudes from the sidelines of the upper half of the bracket 1, and the relay fixture 11 is fixedly installed on both sides of the upper half of the bracket 1, and the distance between the bracket 1 and the relay fixture 11 A closed space is formed b...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is:

[0033] In this embodiment, one side of the one-dimensional numerical control platform is connected to X-ray non-destructive testing equipment. The X-ray non-destructive testing equipment has built-in X-ray tubes and image intensifiers, and the X-ray non-destructive testing equipment is equipped with ball screws. The high-precision force sensor is fixed on the one-dimensional high-precision CNC platform to detect the force of the armature. Wherein, the first sensor 3 and the second sensor 4 are fixed on the one-dimensional numerical control platform 10, the measuring range specification of the first sensor 3 is -10N to +10N, and the measuring range specification of the second sensor 4 is -100N to +100N. It should be noted that the force sensor should be used first to avoid damage to the small force sensor due to exceeding the range. However, when ensuring that the range of the measured force is within 10N, a sm...

Embodiment 3

[0036] The difference between this embodiment and embodiment one and two is:

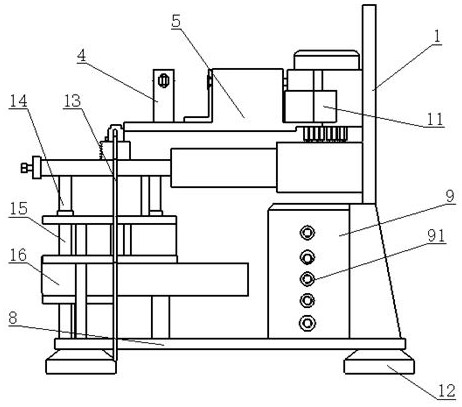

[0037] In this embodiment, the junction box 9 is provided with the interface of a 9-pin plug and a 12-pin plug. One sensor is commonly connected to the 12-pin plug. In the present invention, the electric control box can also be connected with the lead-out lines of the inspection tool through multiple cables. Connect the wiring ports of the electrical control box to the junction box in sequence according to the labels on the junction box. The interface of the electrical control box and the interface of the junction box can realize one-to-one correspondence.

[0038] Three-layer support platforms 16 are arranged below the three-dimensional adjustment mechanism 7, and the support platforms 16 on each floor are connected by platform support columns 15, and the three-dimensional adjustment mechanism 7 is connected with adjacent support platforms 16 by height adjustment columns 14. There are four anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com