Method for determining corrosion performance of bonding interface of bimetal composite material by using a micro-area electrochemical method

A composite material, corrosion performance technology, used in analytical materials, preparation of test samples, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as difficult measurement, and achieve the effect of saving the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

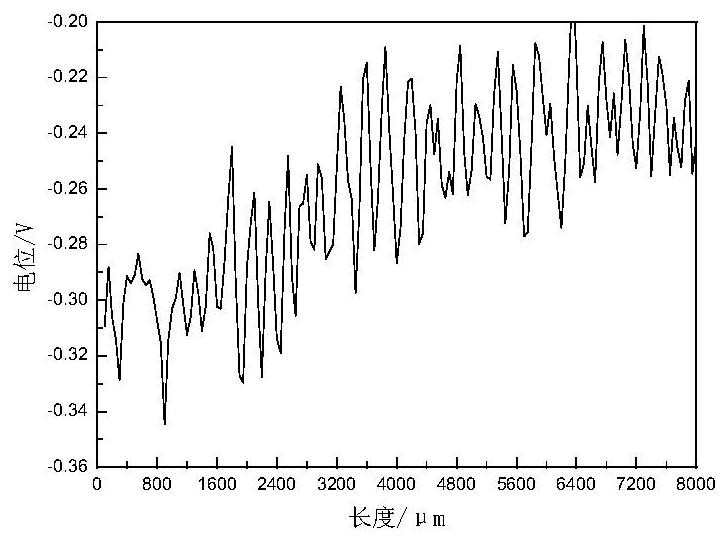

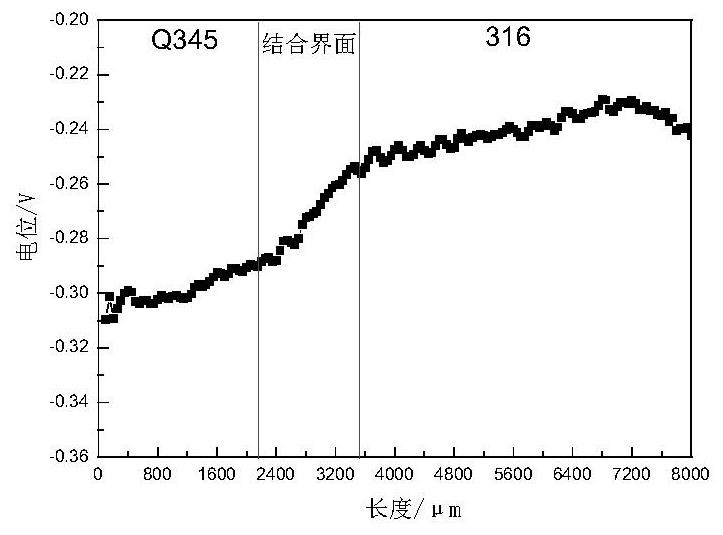

[0068] Research on interface corrosion performance of 316 / Q345 composite plate in simulated industrial atmospheric environment:

[0069] (1) Take a cross-sectional sample of 316 / Q345 composite board with a side length of 30mm×30mm.

[0070] (2) Grind and polish the surface of the section sample step by step, corrode the bonding interface with a metallographic etchant, preliminarily determine and mark the positions of the base material Q345, the bonding interface and the coating 316 stainless steel, and polish the sample again for later use.

[0071] (3) Make molds for creating different thin liquid films (simulating condensation in different atmospheric environments). Take a plastic plate with a thickness of 0.2mm, and use a carving knife to carve out such as figure 1 template shown.

[0072] (4) Configure 0.01mol / L NaHSO 3 The solution simulates the industrial atmosphere, the figure 1 The template is placed on the surface of the cross-section of the composite material, an...

specific Embodiment 2

[0080] Research on interfacial corrosion performance of 2205 / Q235 composite steel bar in simulated marine environment and pastoral atmospheric environment:

[0081] (1) Take a cross-section sample of 2205 / Q235 composite steel bar with a diameter of 32mm and a thickness of 15mm.

[0082] (2) Grind and polish the surface of the section sample step by step, corrode the bonding interface with a metallographic etchant, initially determine and mark the positions of the substrate Q235, the bonding interface and the cladding 2205 stainless steel, and polish the sample again for later use.

[0083] (3) Make molds for creating different thin liquid films (simulating condensation in different atmospheric environments). Take a plastic plate with a thickness of 0.2mm, and use a carving knife to carve out such as figure 1 template shown.

[0084] (4) Configure 0.5% NaCl solution to simulate the marine atmospheric environment, and use deionized water to simulate the pastoral atmospheric en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com