A wellhead foam content detection sensor

A technology for detecting sensor and content, applied in the direction of measurement, instrument, measurement device, etc., can solve the problems of wasting human and material resources, affecting many error factors, low detection accuracy, etc., achieving significant economic benefits, saving labor costs, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

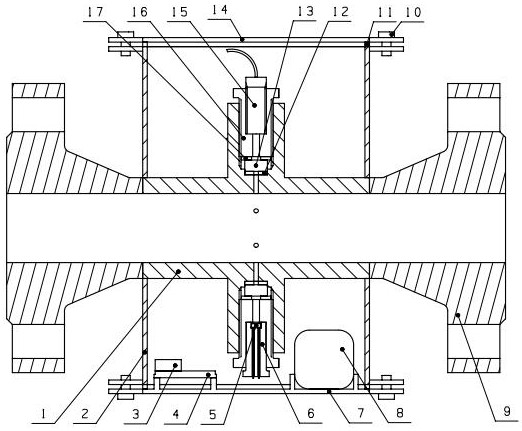

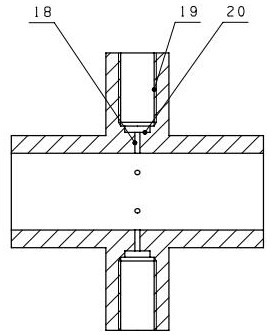

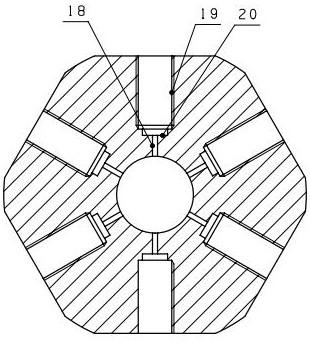

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The infrared emitting head and silicon photovoltaic cell of the present invention are existing products and can be purchased directly. The module is an existing structure and can be purchased directly.

[0023] figure 1 It is a schematic diagram of the overall structure of a wellhead foam content detection sensor of the present invention. The present invention mainly includes a cylinder 1, a lower sealing gasket 12, a tempered glass sheet 13, an upper sealing gasket 17, inner and outer wire fillers 16, and an infrared emitting head 15. , silicon photocell 5, silicon photocell holder 6, battery pack 8, processing circuit 4, wireless transmission module 3, box body 2, box bottom 7, box cover 14, sealing ring 11, bolt 10 and flange 9; the lower gasket The sheet 12 is put into the gasket groove 20, the toughened glass sheet 13 is also put into the gasket groove 20 and above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com