Soft package battery shell insulation impedance test method

A soft pack battery, insulation resistance technology, applied in high resistance measurement, measurement of resistance/reactance/impedance, test of dielectric strength, etc., can solve the problem of not considering the influence of aluminum-plastic film insulation resistance, and achieve comprehensive test results. , The effect of the overall temperature equalization and the precision of quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

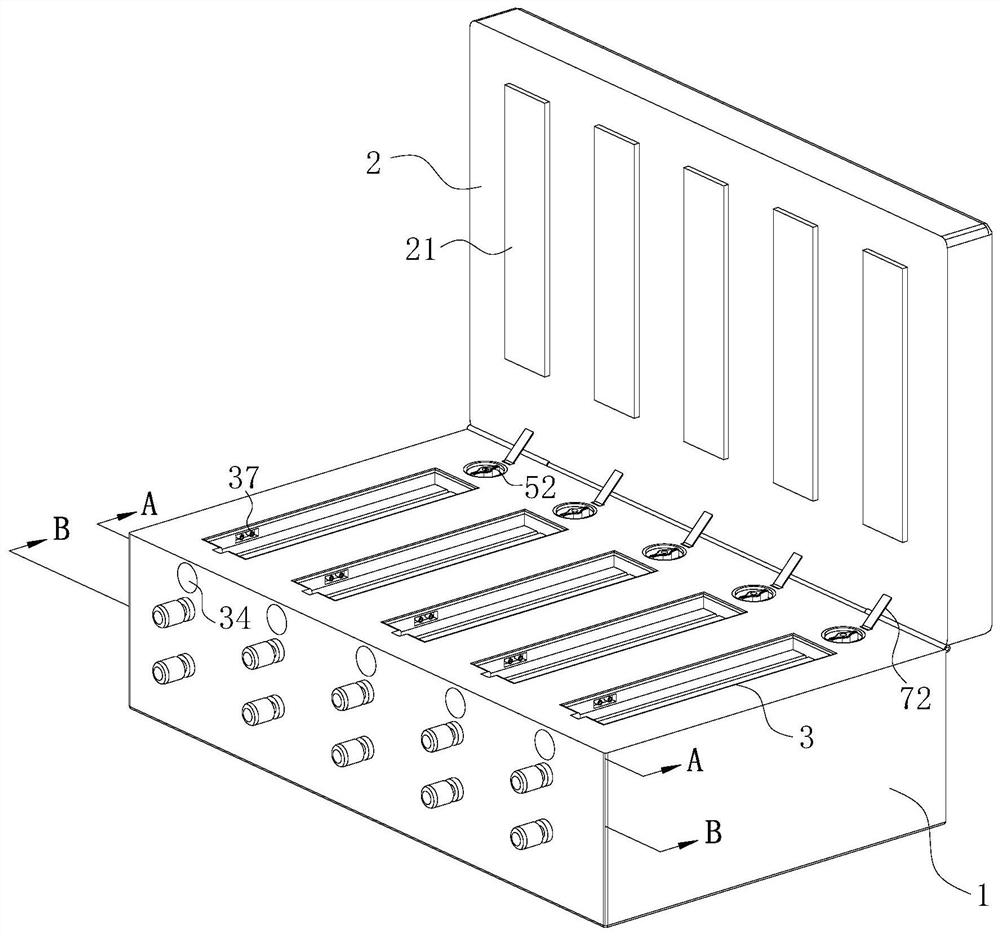

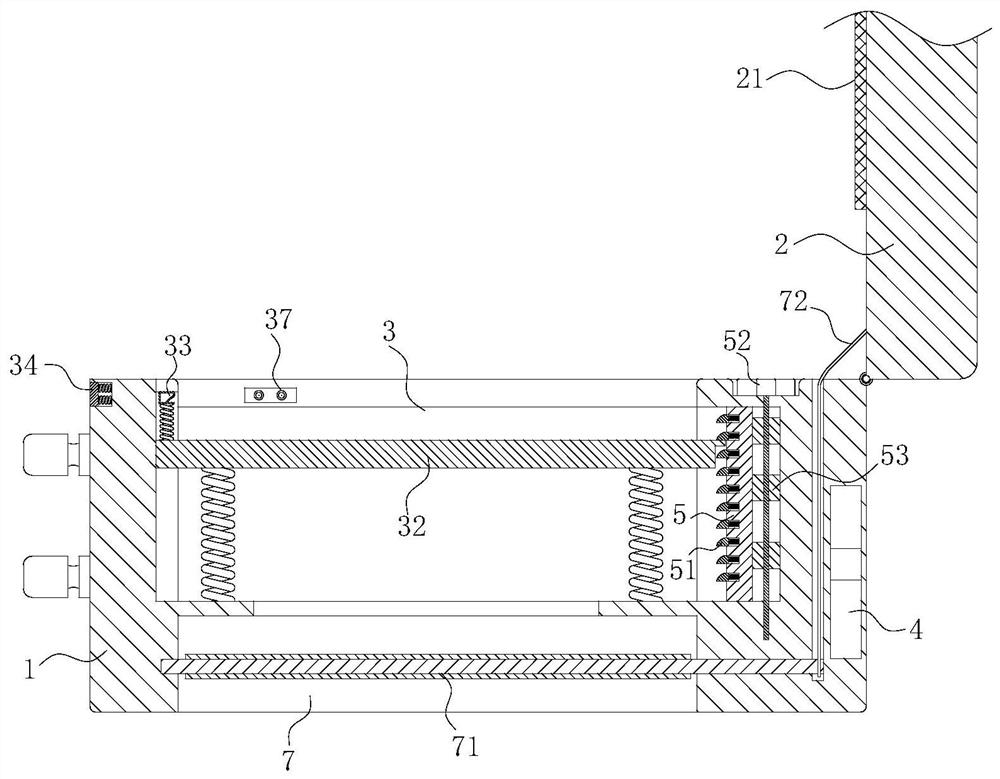

[0042] As an embodiment of the present invention, the extruding block 35 is provided with uniformly distributed telescopic grooves near the side of the test groove 3; a test probe 36 is fixedly connected in the telescopic groove; Connected with a sheath tube 37; the sheath tube 37 is used to protect the test probe 36; because the damage to the surface of the pouch battery caused by the test probe 36 affects its performance, the test probe 36 The diameter of the test probe 36 is small, so that the test probe 36 is susceptible to external shocks and deformation, thereby causing certain obstacles to the testing process. When working, press the pressing rod 34, and the pressing rod 34 extends to the third chute. The extrusion block 35 is extruded, so that the extrusion block 35 slides relative to the pouch battery. During the sliding process, the sheath tube 37 first contacts the side wall of the pouch battery, and as the extrusion block 35 continues to slide, the sheath The tube ...

Embodiment 1

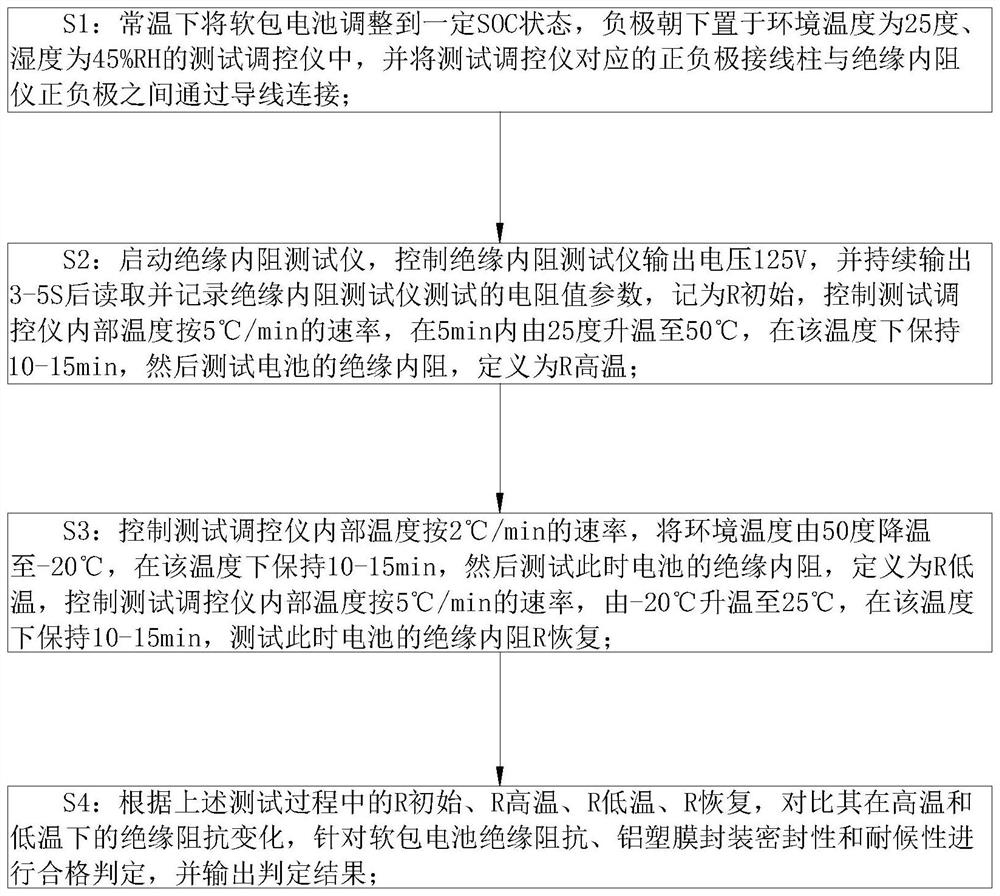

[0051] The insulation properties of two kinds of aluminum-plastic films were compared in experiments. The aluminum-plastic film A and the aluminum-plastic film B were made into 30Ah soft-pack batteries according to the same design and process respectively, and then were tested according to the test method of the present invention:

[0052] 1. At room temperature, first adjust the pouch battery 9 to an 80% SOC state; then place the battery 9 in a high and low temperature box 8 with an ambient temperature of 25 degrees and a humidity of 45% RH;

[0053] 2. The insulation internal resistance tester 12 is outside the high and low temperature box 8, and the battery aluminum-plastic film case 11 is connected to the positive end of the insulation internal resistance tester 12 through wires, and the negative electrode ear 10 of the soft pack battery 9 is connected to the insulation internal resistance tester. The negative terminals of 12 are connected to each other; set the insulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com