Electric leakage protection method and system for mining variable-frequency driving system

A technology of leakage protection and variable frequency drive, which is applied in the direction of automatic disconnection emergency protection devices, emergency protection circuit devices, electrical components, etc., can solve the problems of loss of hierarchical protection, lower sensitivity, and mutual influence, so as to improve safety and improve Effects on Safety and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

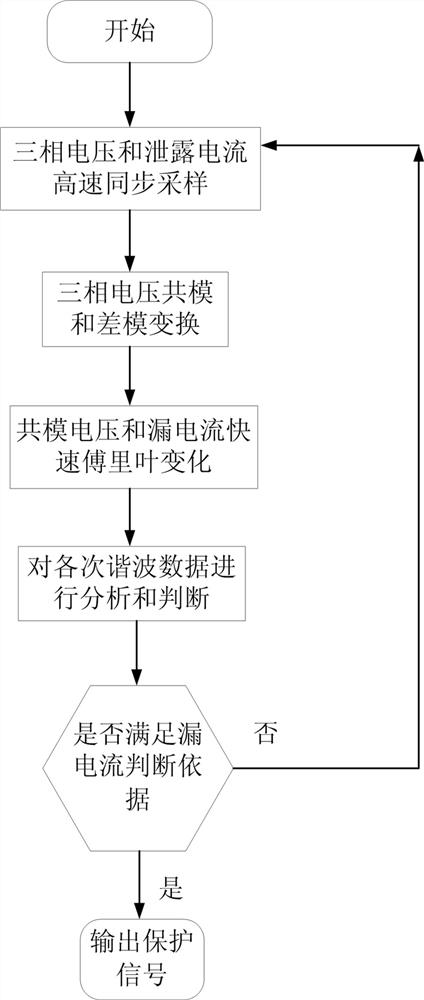

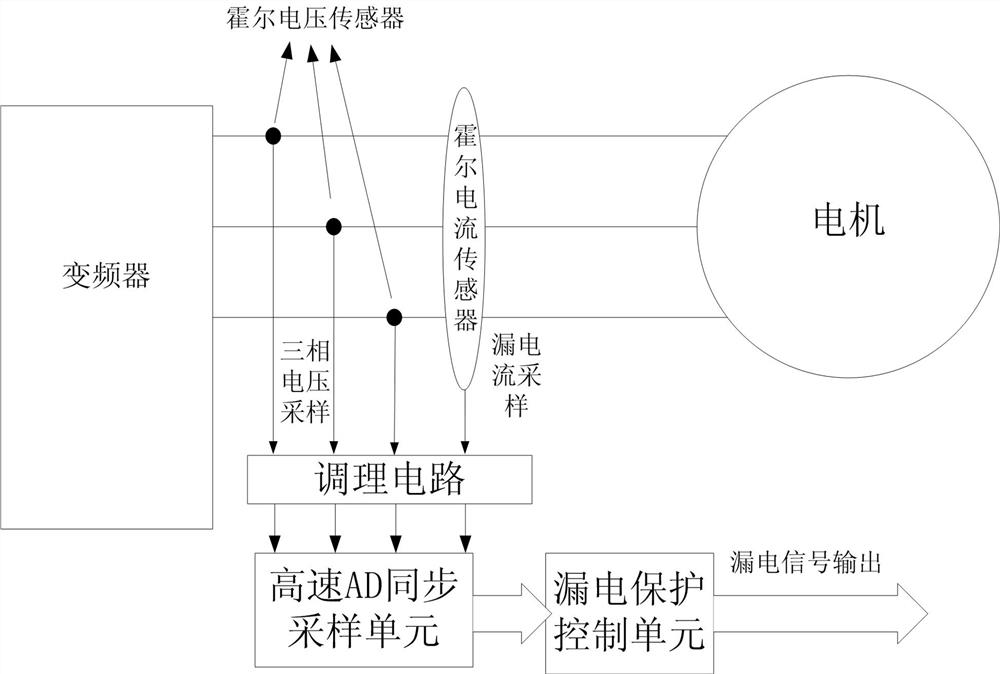

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a mine-used variable frequency drive system leakage protection method, including the following steps:

[0032] S1. High-speed sampling: four-way synchronous sampling is performed on the three-phase output voltage of the inverter and the ground leakage current to obtain the sampling instantaneous value u of the three-phase output to the DC neutral point voltage a , u b and u c , and the sampled instantaneous value i of the ground leakage current, the instantaneous value i of the ground leakage current is taken as the common mode current.

[0033] S2. Common-mode transformation: Perform common-mode transformation on the measured three-phase voltage to obtain the common-mode voltage value u, and the transformation formula is:

[0034] ;(1)

[0035] Among them, k 1 、k 2 、k 3 represent the common-mode transformation coefficients respectively, and there are k 1 +k 2 +k 3 =3. The common-mo...

Embodiment 2

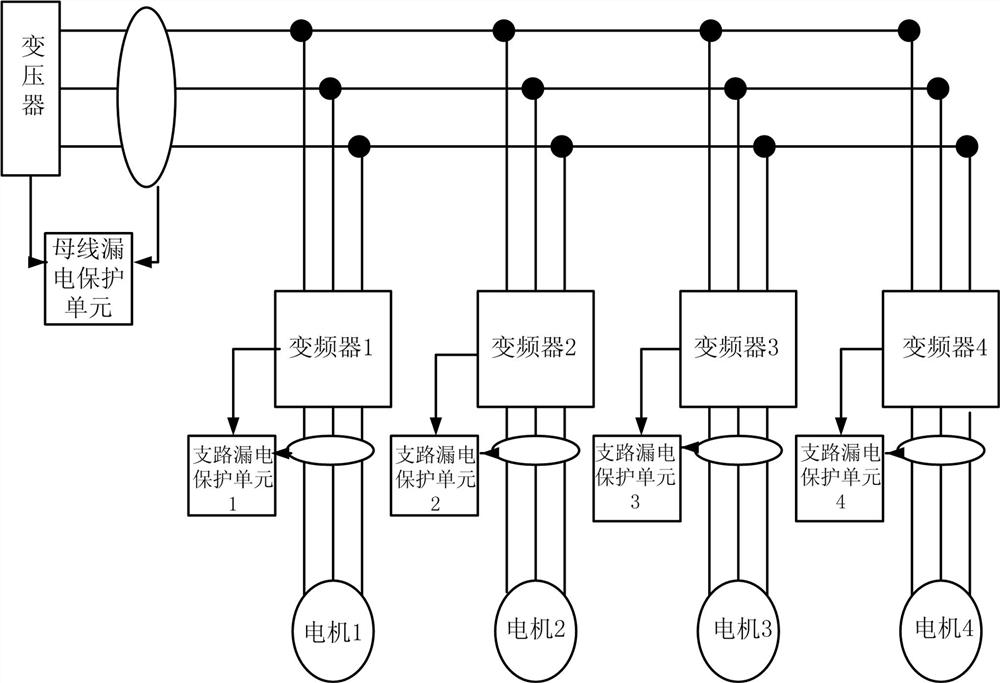

[0050] Such as image 3 As shown, Embodiment 2 of the present invention provides a leakage protection system for mine-used variable frequency drive system including 5 such as figure 2 In the mine variable frequency drive system leakage protection unit shown, among the 5 mine frequency conversion drive system leakage protection units, one of them is set on the bus as a bus protection unit, and the other 4 are set as branch circuit leakage protection units on each On the output terminal of the branch frequency converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com