Motor based on pulsating heat pipe

A technology of pulsating heat pipes and casings, applied in the field of motors, can solve the problems of high temperature of stator components, temperature rise, wear of mechanical parts, etc., and achieve the effects of improving cooling efficiency, reducing motor volume, and high heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

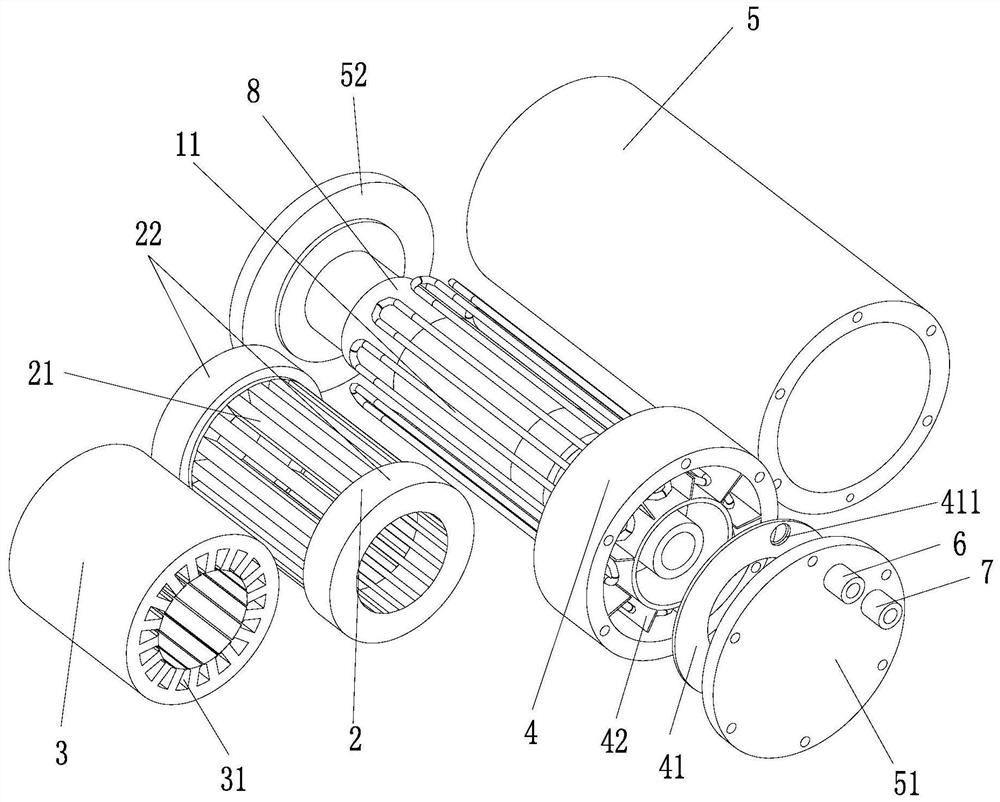

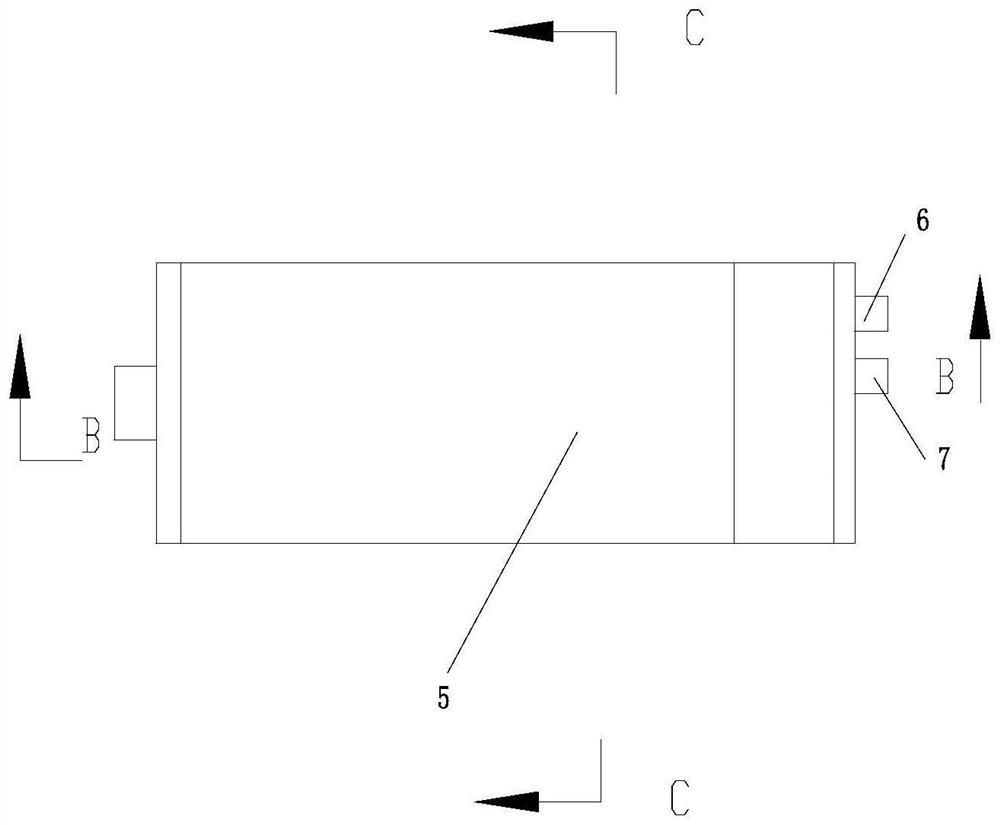

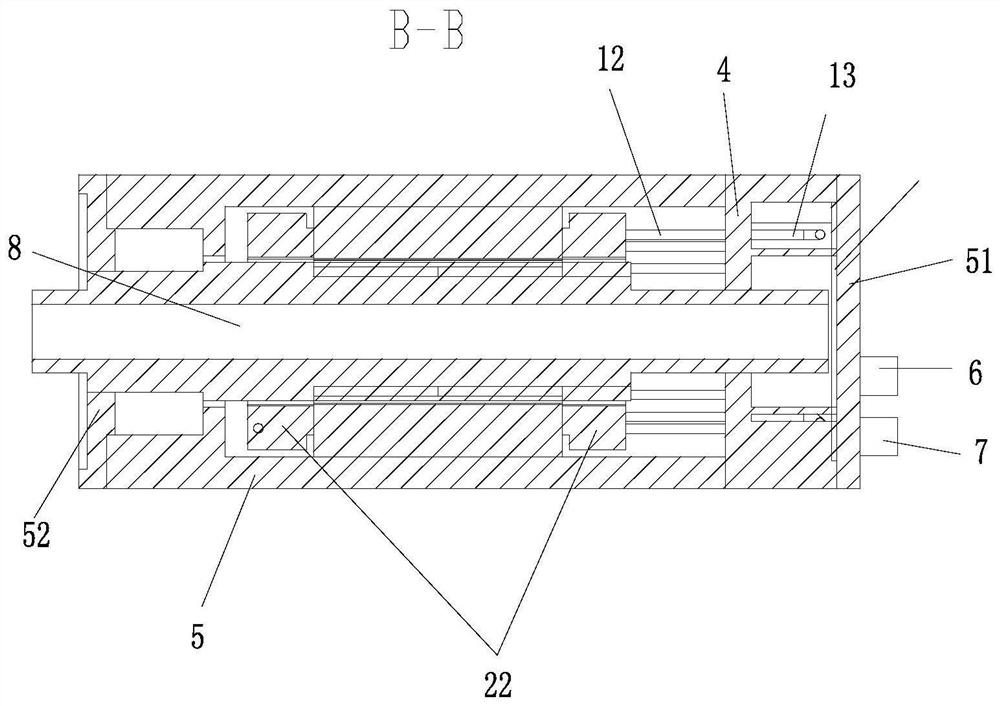

[0025] Please refer to Figure 1 to Figure 5 , the present invention provides a motor based on a pulsating heat pipe, comprising a stator winding 2, a stator core 3, and a central shaft 8, wherein the stator winding 2, the stator core 3, and the central shaft 8 are coaxially arranged; the stator core 3 is arranged along its diameter There are a plurality of stator slots 31 for placing windings; it also includes a pulsating heat pipe 1, and the pulsating heat pipe 1 includes a condensation section 13 and an evaporation section 11; in the radial direction of the stator core 3, the pulsating heat pipe 1 in the stator slot 31 The evaporation section 11 is located between the bottom of the stator slot 31 and an effective edge 21 of the stator winding 2 .

[0026] Herein, "effective side" refers to the straight part of the stator winding embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com