Industrial waste gas purifier

A technology of industrial waste gas and purifier, which is applied in chemical instruments and methods, gas treatment, dispersed particle filtration, etc., can solve the problems of large aeration volume, insufficient floc volatilization, serious acid loss of biofilm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

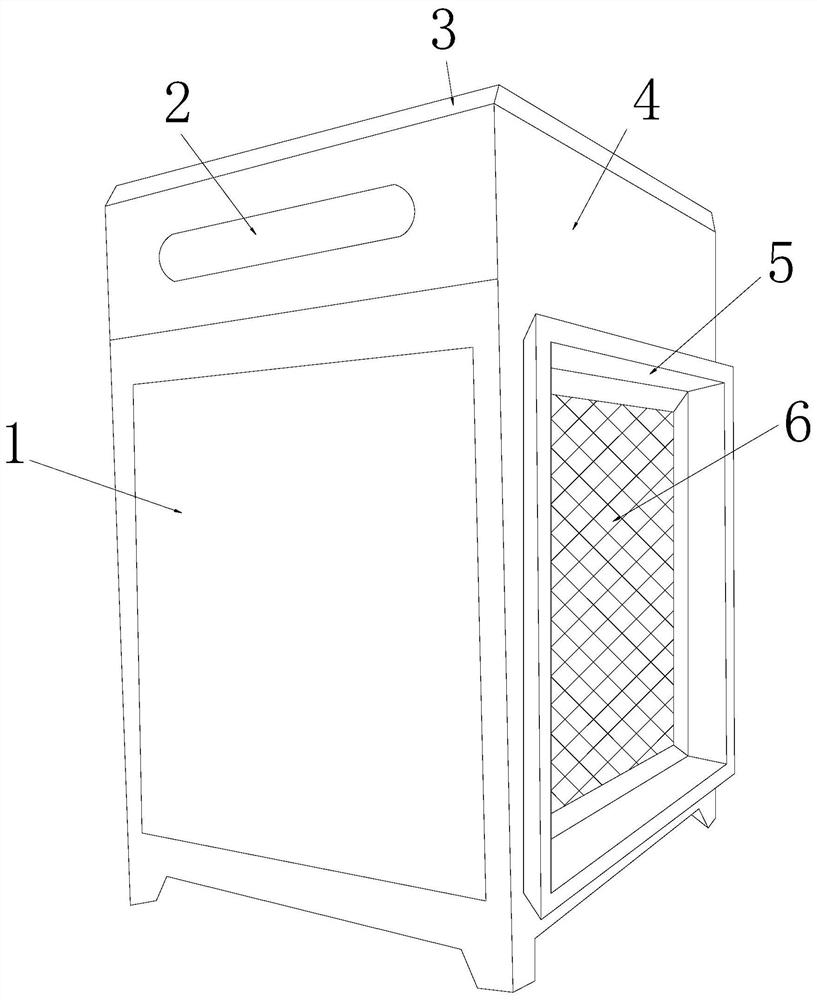

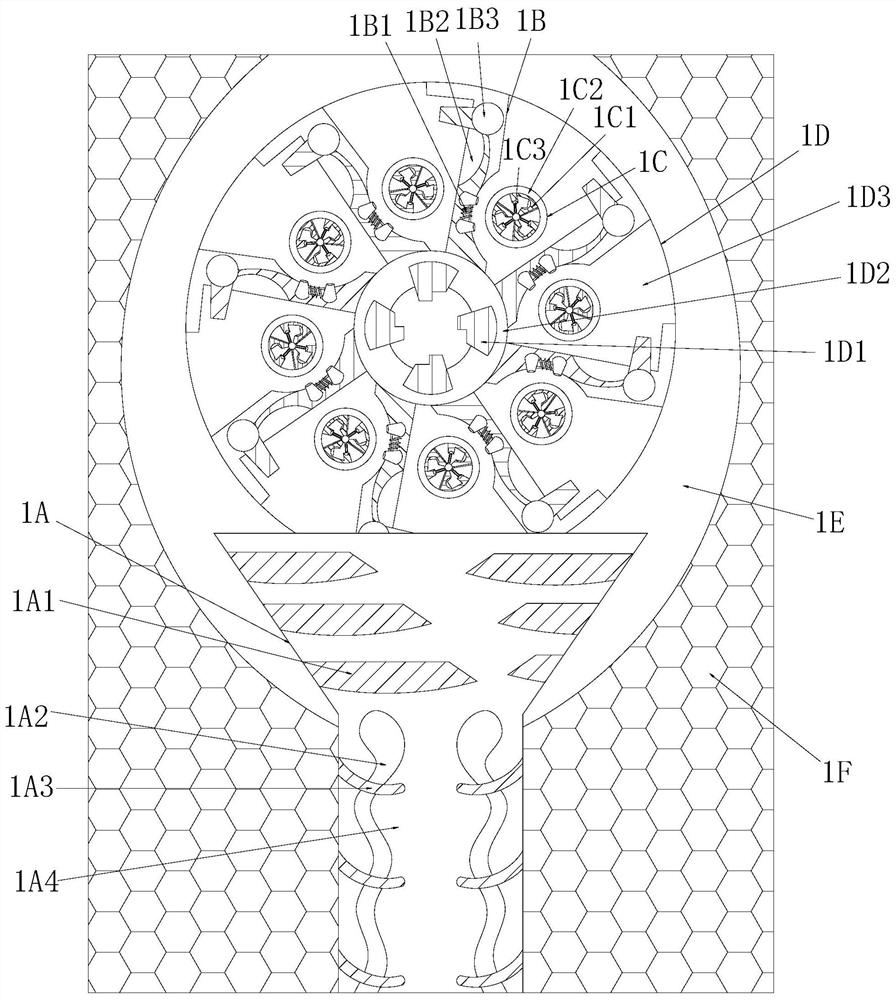

[0033] see Figure 1-Figure 6, the present invention provides an industrial waste gas purifier, the structure of which includes: a wheel guide funnel frame groove 1, an exhaust bar groove 2, a top cover plate 3, a purifier shell 4, a square frame slot 5, a filter screen plate 6. The wheel guide funnel frame groove 1 is nested on the left side of the filter screen plate 6 and communicates with each other. The filter screen plate 6 is inserted into the inside of the square frame notch 5 and is on the same vertical plane. The square frame notch 5 is welded on the right side of the purifier housing 4, the top cover plate 3 and the purifier housing 4 adopt an interference fit, and the exhaust bar groove 2 and the purifier housing 4 are Integral structure and interpenetrating with each other, the wheel guide funnel rack slot 1 is inserted into the interior of the purifier housing 4, the wheel guide funnel rack slot 1 is provided with a condenser funnel 1A, a suction liquid plate 1B,...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides an industrial waste gas purifier, other aspects are the same as in Embodiment 1, the difference is:

[0041] see figure 2 , the inner clip ring disk 1D is composed of an inner clip plate 1D1, a wheel ring body 1D2, and an air disturbance disk body 1D3, and the inner clip plate 1D1 is closely attached to the front side of the wheel ring body 1D2 and is in the same vertical On the surface, the ring body 1D2 is mechanically connected with the air disturbing disk body 1D3 and the axes are collinear, and the inner clamping plate 1D1 is used to form the operation effect of the swirling airflow around the fixed axis at the axis of the air disturbing disk body 1D3.

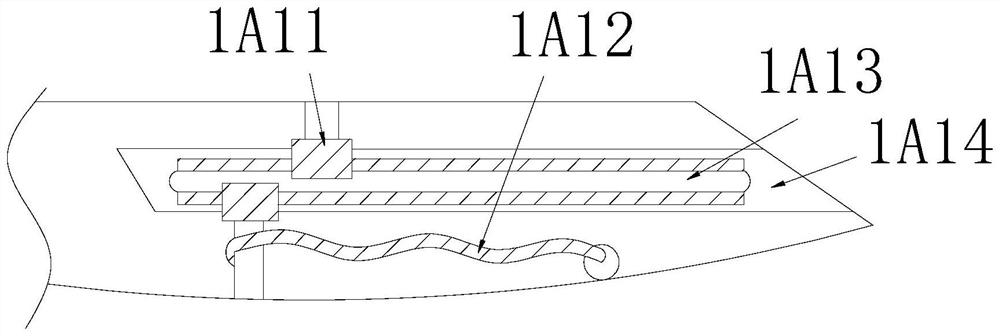

[0042] see Image 6 , the inner clamping plate 1D1 is composed of a liner plate 1D11, an arc plate threaded ring 1D12, an inner wing plate 1D13, and a frame side strip 1D14, and the liner plate 1D11 and the arc plate threaded ring 1D12 adopt an interference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com