Conductive TPU film and preparation method thereof

A conductive and thin-film technology, applied in the field of conductive TPU thin film and its preparation, can solve the problems of further improvement of conductive performance, and achieve excellent conductive and mechanical properties, high mechanical properties, and good road performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

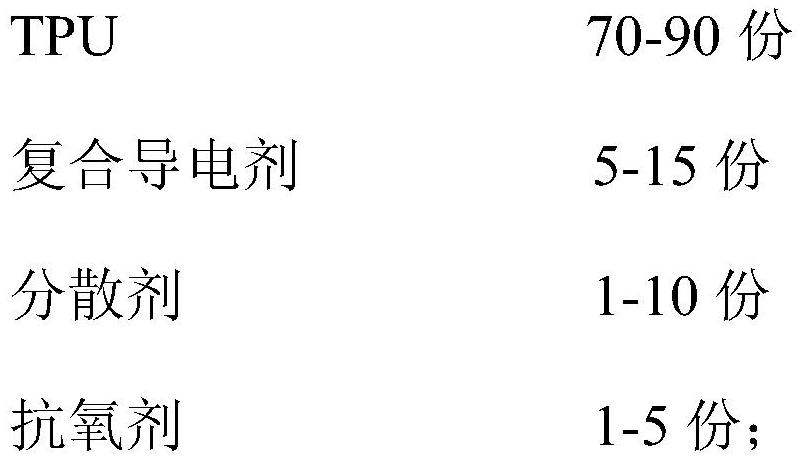

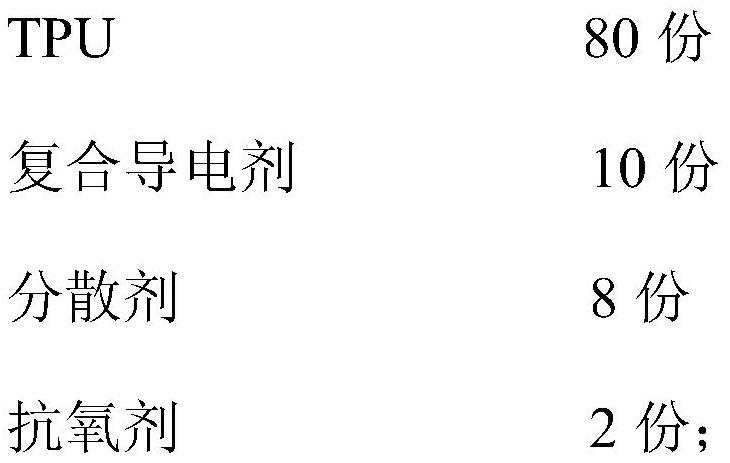

[0036] A kind of conductive TPU film of the present embodiment, by weight, comprises the following components:

[0037]

[0038]Among them, the composite conductive agent is a mixture of carboxylated single-walled carbon nanotubes and 1-naphthoic acid modified graphene doped with rare earth metals, and 1-naphthoic acid modified graphene with carboxylated single-walled carbon nanotubes and doped rare earth metal europium The mass ratio of the graphene is 5:3, and the mass percentage of the rare earth metal to the mass of the 1-naphthoic acid modified graphene doped with the rare earth metal is 4%.

[0039] Wherein, the preparation method of composite conductive agent is:

[0040] a) mix divalent rare earth metal europium ions, ethanol and 1-naphthoic acid modified graphene, and obtain 1-naphthoic acid modified graphene doped with rare earth metal after drying; The percentage of 1-naphthoic acid modified graphene mass is 4%;

[0041] b) mixing carboxylated carbon nanotubes ...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that the mass ratio of carboxylated single-walled carbon nanotubes to 1-naphthoic acid-modified graphene doped with rare earth metal europium is 5:1, and the others are the same as in embodiment 1. .

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is that the mass ratio of carboxylated single-walled carbon nanotubes to 1-naphthoic acid modified graphene doped with rare earth metal europium is 10:1, and the others are the same as in embodiment 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com