A prefabricated steel cage quick docking device and its construction method

A technology of docking device and reinforcement cage, which is applied in basic structure engineering, construction material processing, construction, etc., can solve the problem of slow construction progress of steel cage straight thread sleeve connection, reducing the overall construction progress of reinforcement cage docking, time-consuming and manpower-consuming, etc. problems, to achieve the effect of improving construction efficiency, convenient movement and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-4 The application is described in further detail.

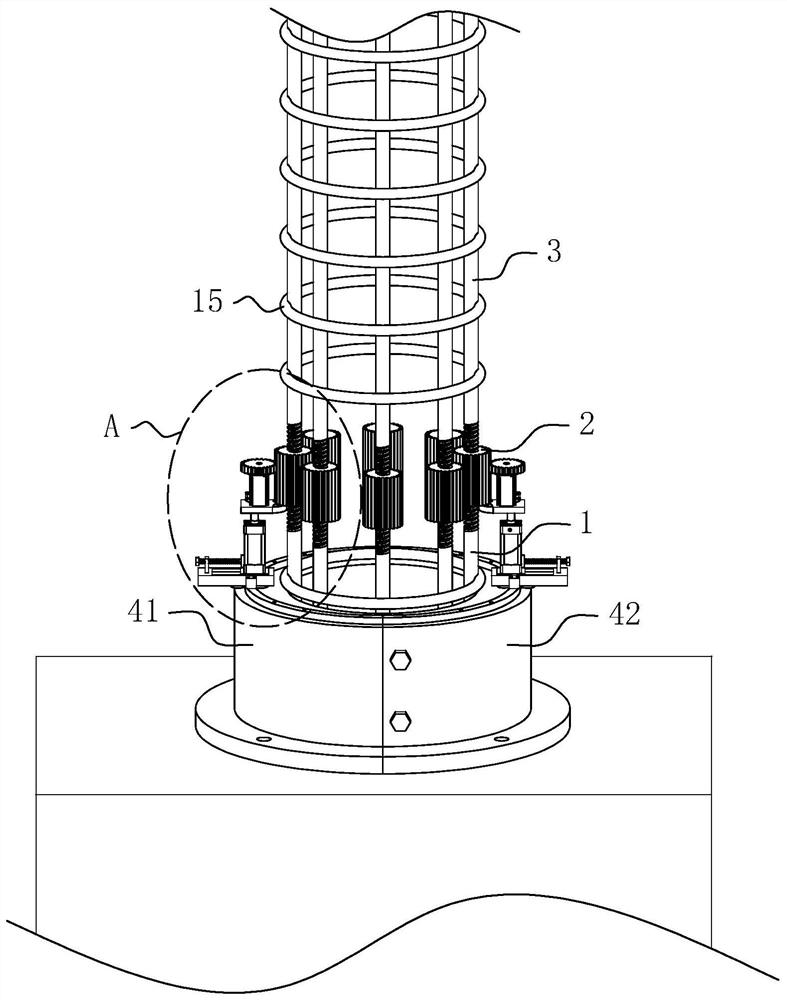

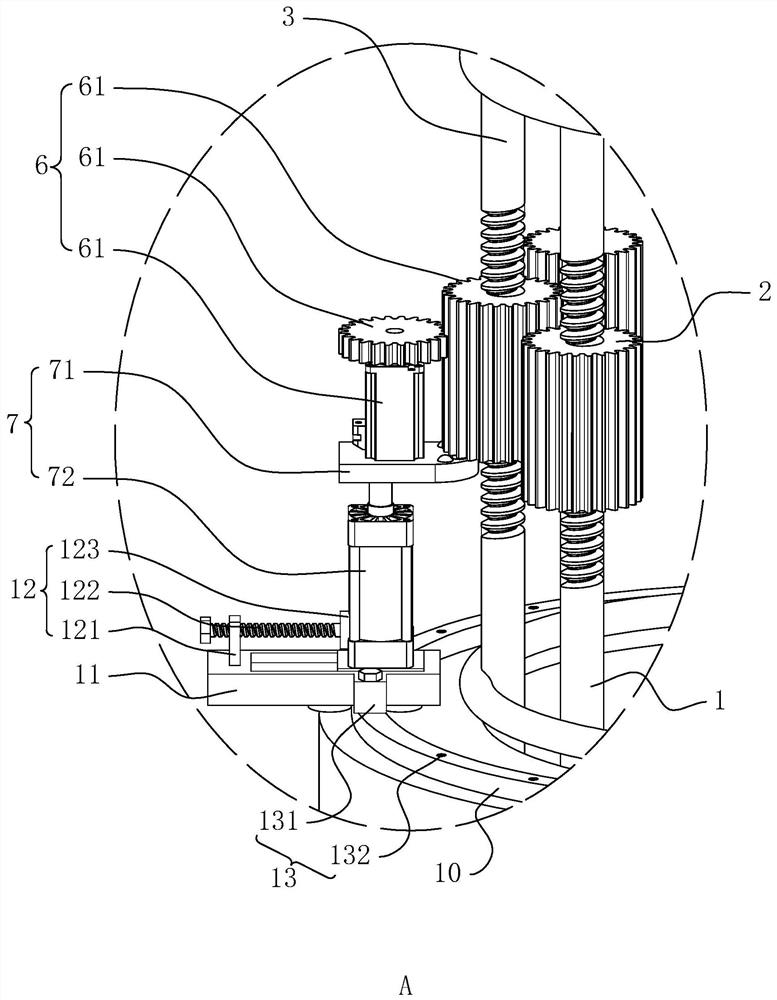

[0047] The embodiment of the present application discloses a quick docking device for prefabricated reinforcement cages. refer to figure 1 , the docking device includes a lower reinforcement cage arranged in the deep pit, the lower reinforcement cage is composed of a plurality of vertically arranged lower main reinforcements 1 and annular stirrups 15 sleeved outside the plurality of main reinforcements; The threaded sleeve 2 on the top of the lower main rib 1, the threaded sleeve 2 is set as the positive and negative wire straight threaded sleeve 2; it also includes a plurality of upper main ribs 3 arranged vertically, and the outer side walls of the upper main ribs 3 are also welded at intervals. Ring stirrup 15.

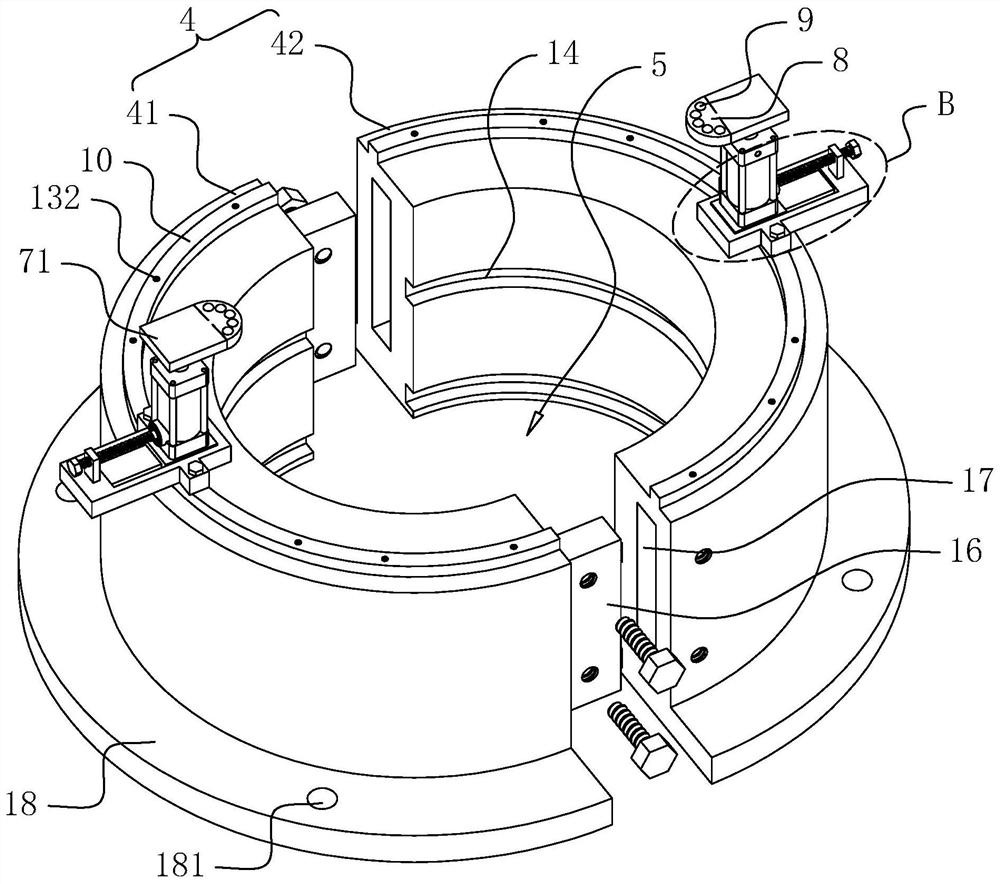

[0048] refer to figure 1 and figure 2 , also includes the limit card seat 4 that is used to define the lower reinforcement cage, the limit card seat 4 includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com