A method for optimizing soaking time of shale gas wells after volume fracturing

A volume fracturing and shale gas well technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problem of inability to reflect the law of micro-fracture initiation, many simplification factors in theoretical models, and large differences in shale gas wells and other problems, to achieve the effect of simple and feasible test method, improving efficiency and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

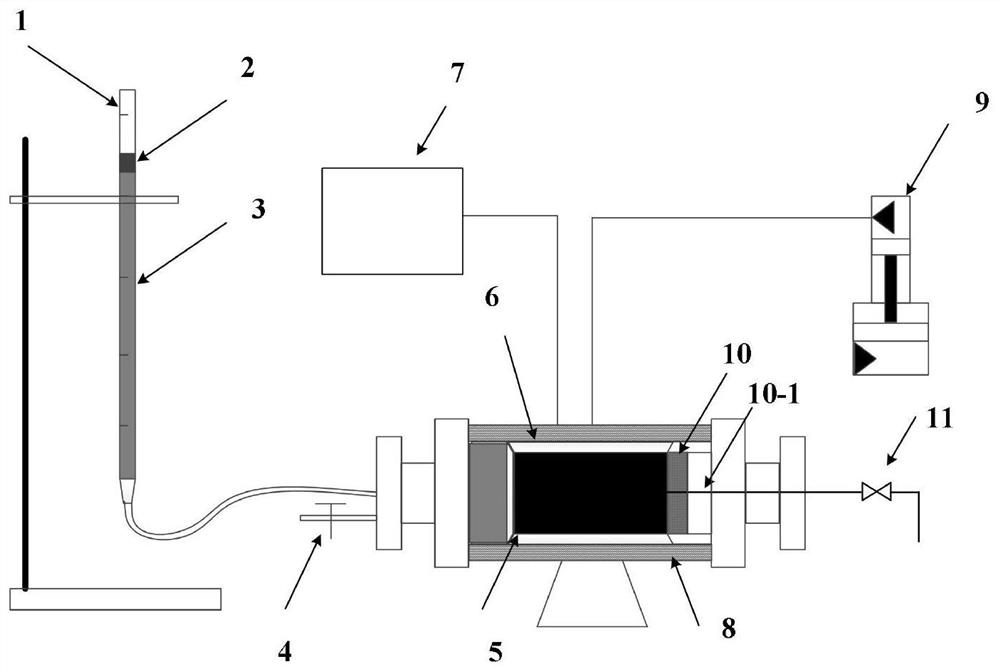

Method used

Image

Examples

example

[0081] Taking an actual on-site calculation example as an example, the specific implementation of the present invention will be described in detail below based on the accompanying drawings and shale wells in the southern Sichuan region of the Sichuan Basin as an example. details as follows:

[0082] The specific implementation of the present invention will be described in detail below with reference to the accompanying drawings and the shale wells in the southern Sichuan region of the Sichuan Basin as an example. details as follows:

[0083] (1) Preparation of rock samples: The actual downhole cores of 15 shale gas wells, numbered P1-P15, were taken at a depth of 2500-2620m, and standard rock samples with a diameter of 2.5cm and a length of 5cm were prepared 15 pieces, the number of rock samples is Y1~Y15, and placed in a 100°C oven to dry to constant weight, and the imbibition area A of the rock sample and the actual length L of the measured rock sample are calculated accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com