Controllable coolant pump with a filter disc, filter disc, and the production thereof

A coolant pump and filter technology, applied in the cooling of the engine, the components of the pumping device for elastic fluid, pump control, etc., can solve the problem of damage to the coolant pump adjustment behavior, to maintain dimensional stability, Improvement of dynamic sealing, effect of reducing leakage flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

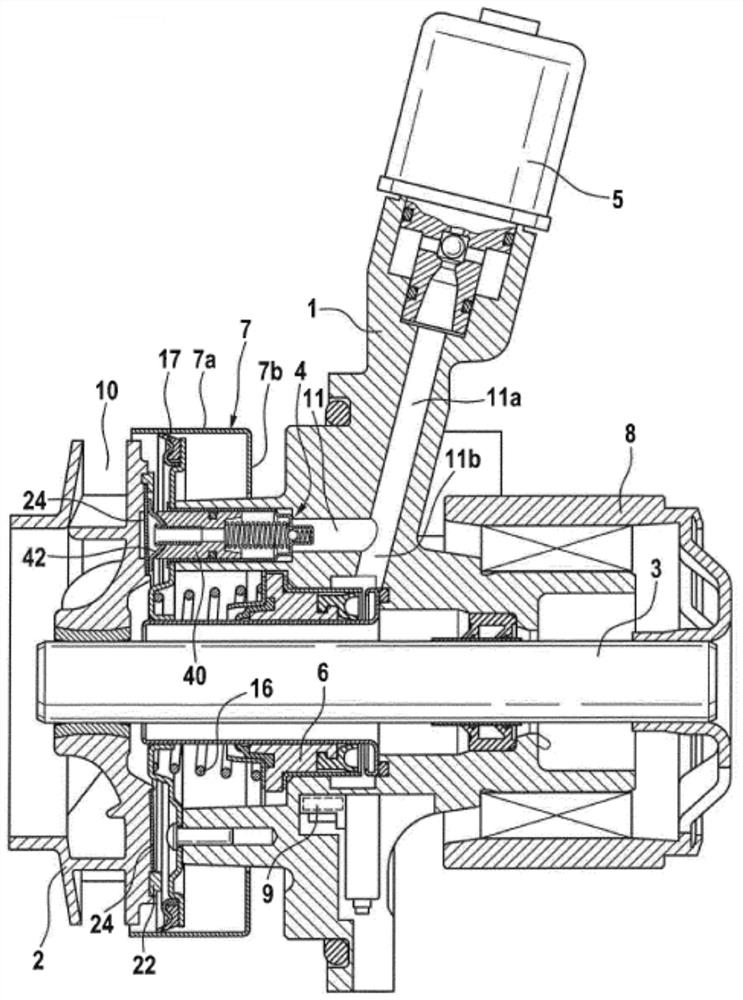

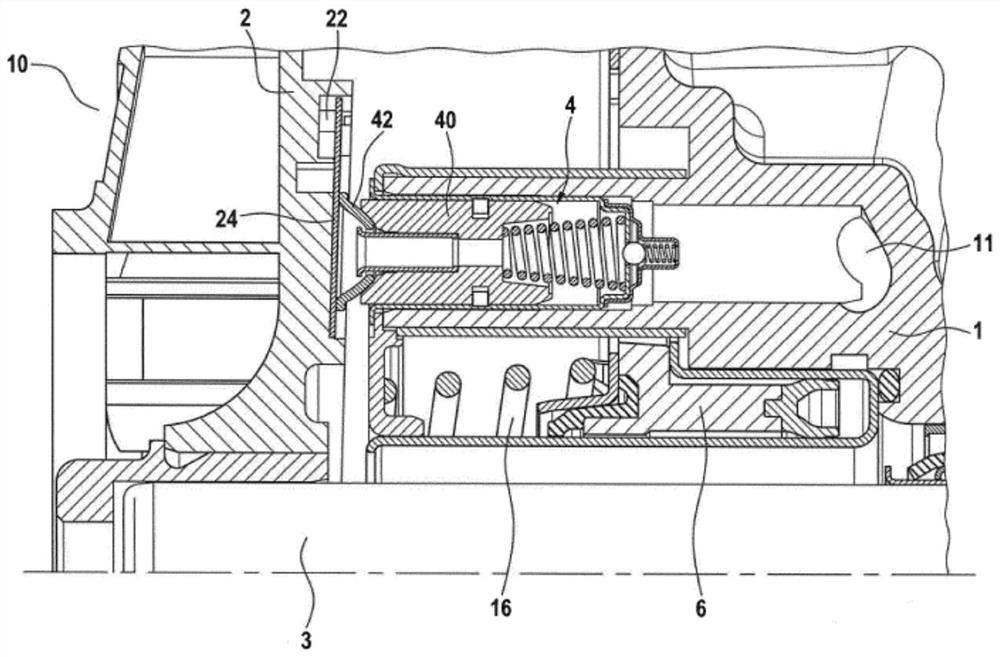

[0034] reference here figure 1 and 2 Describe the structure of the coolant pump.

[0035] like figure 1 The coolant pump shown comprises a pump housing 1 and a pump shaft 3 rotatably mounted therein, which has a pulley 8 which is driven by a belt drive of a not shown internal combustion engine. Arranged for co-rotation at the free end of the pump shaft 3 is an impeller 2 , which is integrated in a pump chamber 10 in the flow region of the coolant circuit of the internal combustion engine in order to achieve a volume flow of the coolant. Coolant is sucked into the central area of the impeller 2 through an axial inlet (not shown) of the pump chamber 10 and discharged through a radial outlet (not shown) of the pump chamber 10 opposite the peripheral area of the impeller 2 .

[0036] The flow area of the impeller 2 can be covered in a variably manner by means of an adjusting slide 7 which has a cylindrical section 7 a arranged coaxially with the pump shaft 3 and a rear e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com