Full-automatic pitting and cutting method and equipment for fruits

A fully automatic, fruit technology, applied in fruit de-pitting devices, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as restricting large-scale production of products, declining product quality, and unstable quality, and achieving a wide range of applications. , the effect of improving efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

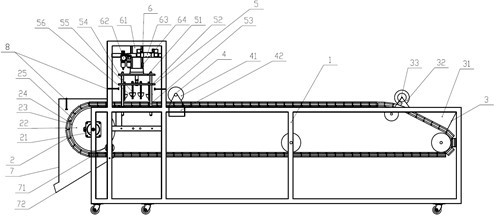

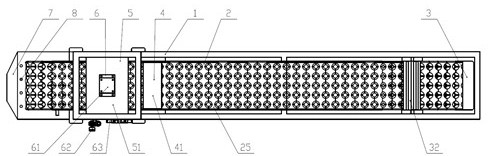

[0057] Example: such as figure 1 , 2 As shown, the fully automatic fruit pitting and cutting equipment is mainly composed of a frame 1, a transmission mechanism 2, a feeding mechanism 3, a peeling mechanism 4, a punching and cutting mechanism 5, a power mechanism 6, a discharge device 7 and a self-cleaning device 8 composition.

[0058] The frame 1 is used to support other mechanisms.

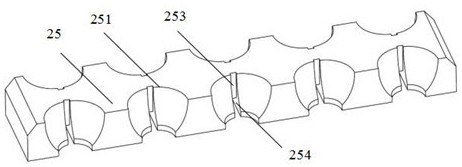

[0059] The transmission mechanism 2 is integrally installed on the frame 1 and includes a driving motor 21 , a transmission wheel 22 , a transmission chain 23 and a transmission belt 24 . The drive motor 21 is fixedly mounted on the front end of the frame 1; the drive wheel 22 center is fixedly connected with the drive motor 21 rotating shaft, and the rotation of the motor 21 rotating shaft drives the drive wheel 22 to rotate; the transmission chain 23 is connected with the drive wheel 22 as a rack and pinion, and Two pallets 25 for core removal and cutting are parallel and transversely form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com