A hardware kitchenware grinding and polishing device for hardware production

A polishing device and hardware technology, applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of single fixture response situation and low working efficiency of the grinding and polishing device, so as to solve the fixture response situation Single, solve the effect of low work efficiency and improve grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

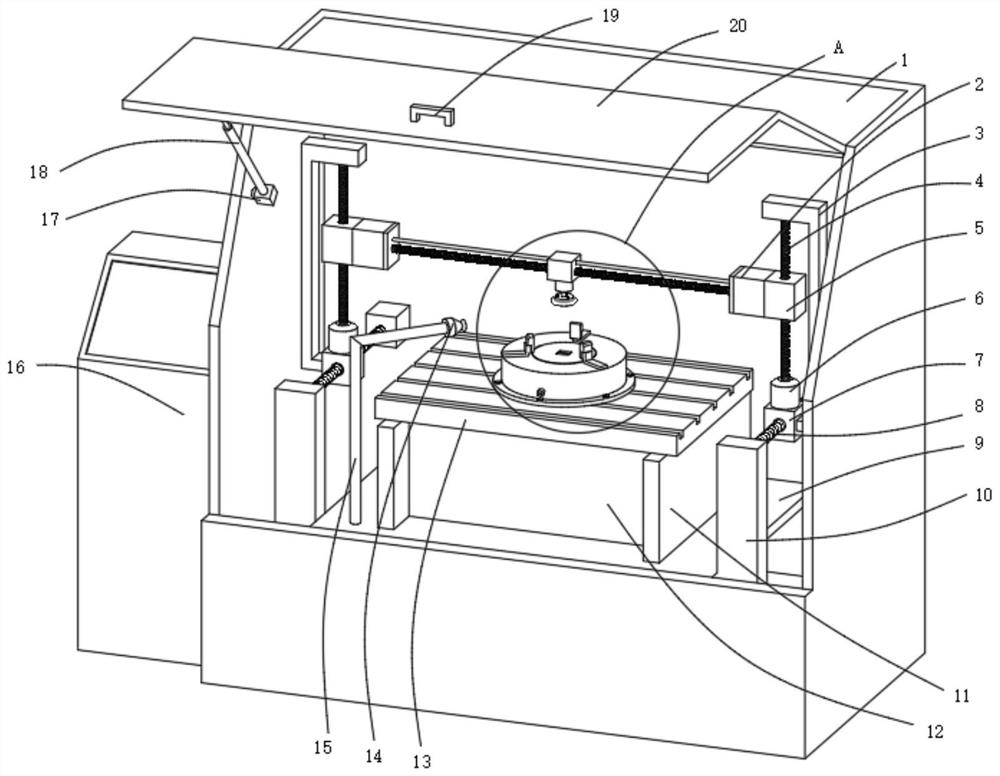

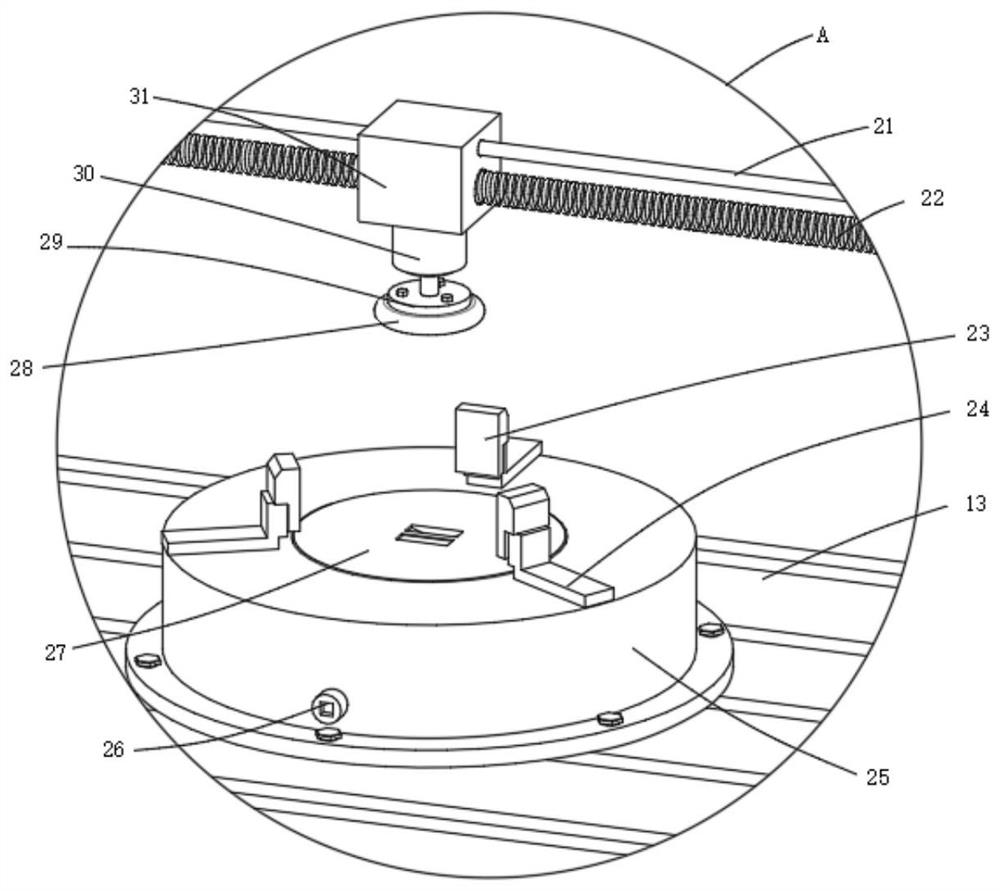

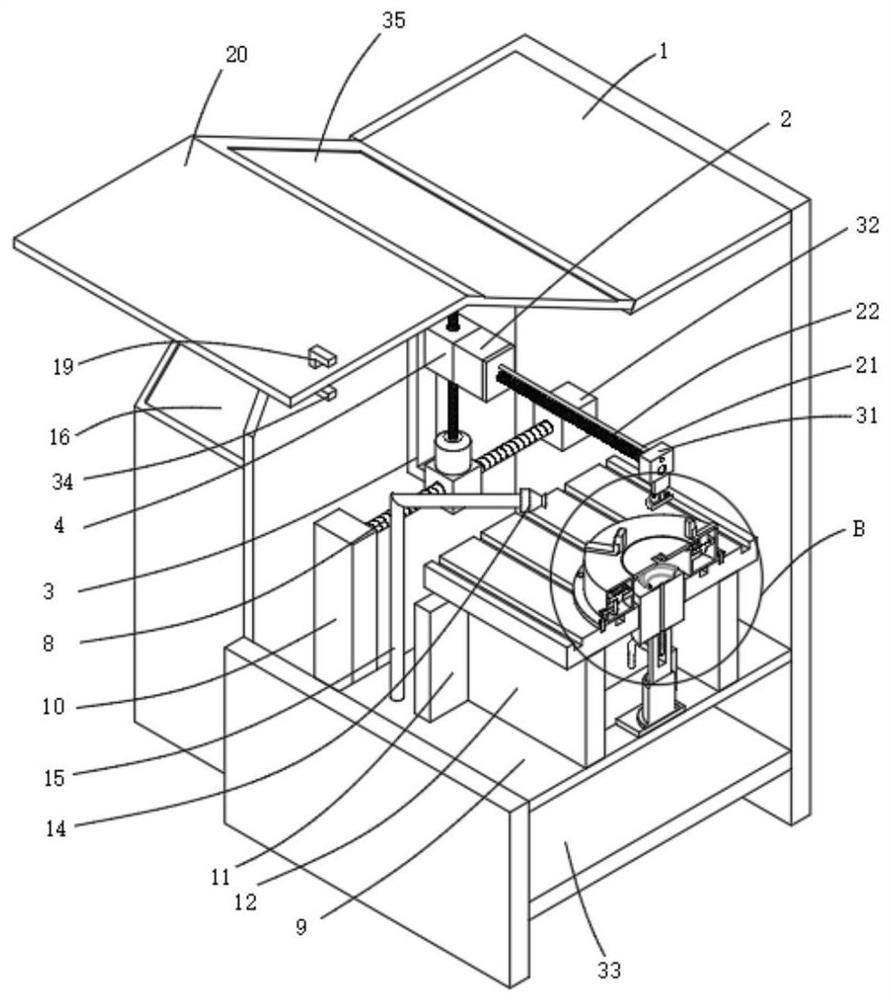

[0029] see Figure 1-6 , the present invention provides the following technical solutions: a hardware kitchenware grinding and polishing device for hardware production, including a box body 1, a first servo motor 32 is fixedly connected to the back plate of the box body 1, and the output end of the first servo motor 32 is fixedly connected to a The first lead screw 8, one end of the first lead screw 8 is movably connected with a fixed square column 10, the front of the fixed square column 10 is fixedly connected with the inner surface of the box body 1, and the outer surface of the first lead screw 8 is threadedly connected with The first moving block 7, one side of the first moving block 7 is fixedly connected with a fixed frame 3, the upper surface of the first moving block 7 is fixedly connected with a vertical servo motor 6, and the output end of the vertical servo motor 6 is fixedly connected with a vertical Straight lead screw 4, one end of vertical lead screw 4 is flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com