Rope winding device of hoisting equipment for power cable

A technology for power cables and equipment, applied in the field of rope winding devices, can solve problems such as uneven winding, easy loosening of cables, easy pulling of cables, etc., and achieve the effect of facilitating subsequent processing, proper tightness, and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

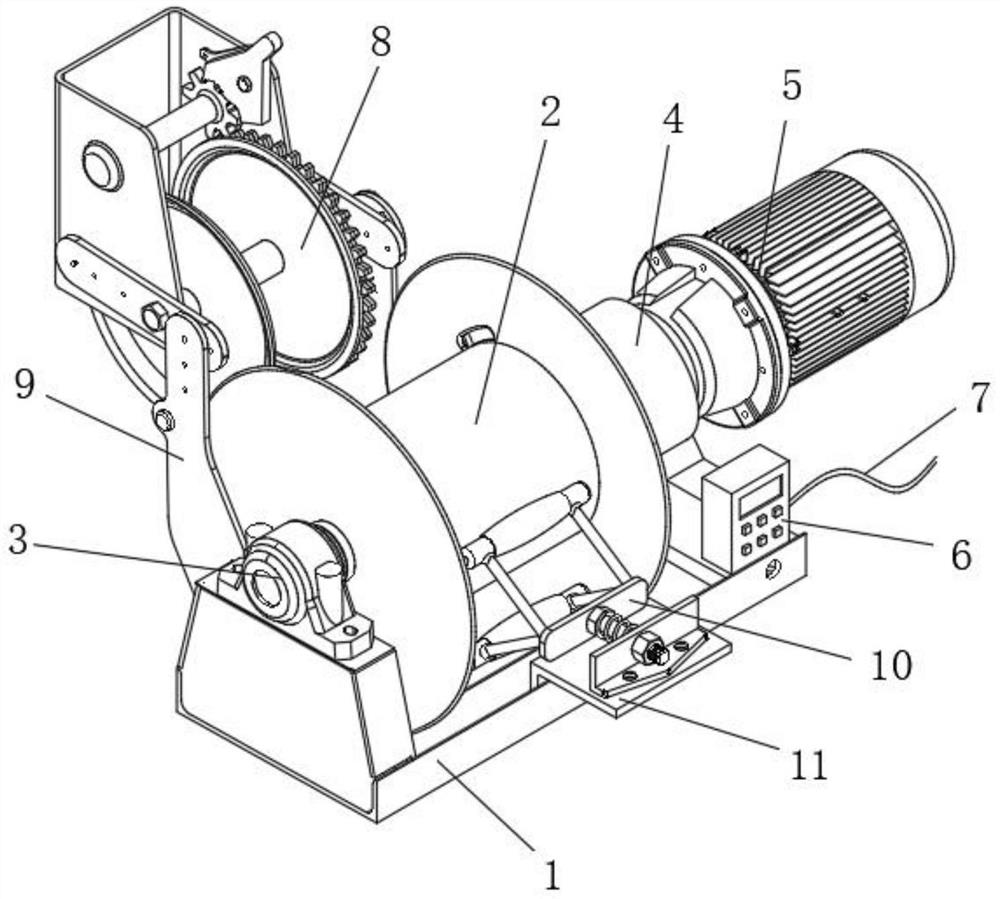

[0032] see figure 1 As shown, the present invention provides a rope winding device for hoisting equipment for power cables through improvement, including a support base 1, a reel 2, a shaft seat 3, a reel shaft 4, a drive motor 5, a control panel 6, an external connection Power cord 7, auxiliary winding device 8, longitudinal mounting frame 9, auxiliary flattening device 10 and horizontal mounting frame 11, a reel 2 is arranged on the support base 1, and the two sides of the reel 2 are installed on the support base through the shaft seat 3 1, the set reel 2 can be used for cable winding, the right end of the reel 2 is provided with a reel shaft 4, the bottom of the drive motor 5 is fixed to the support base 1, and its output shaft is connected to the reel shaft 4 Connected by the coupling, after the driving motor 5 works, the reel shaft 4 can be driven to rotate, and then the reel shaft 4 can drive the reel 2 to rotate, and the front right side of the support base 1 is provide...

Embodiment 2

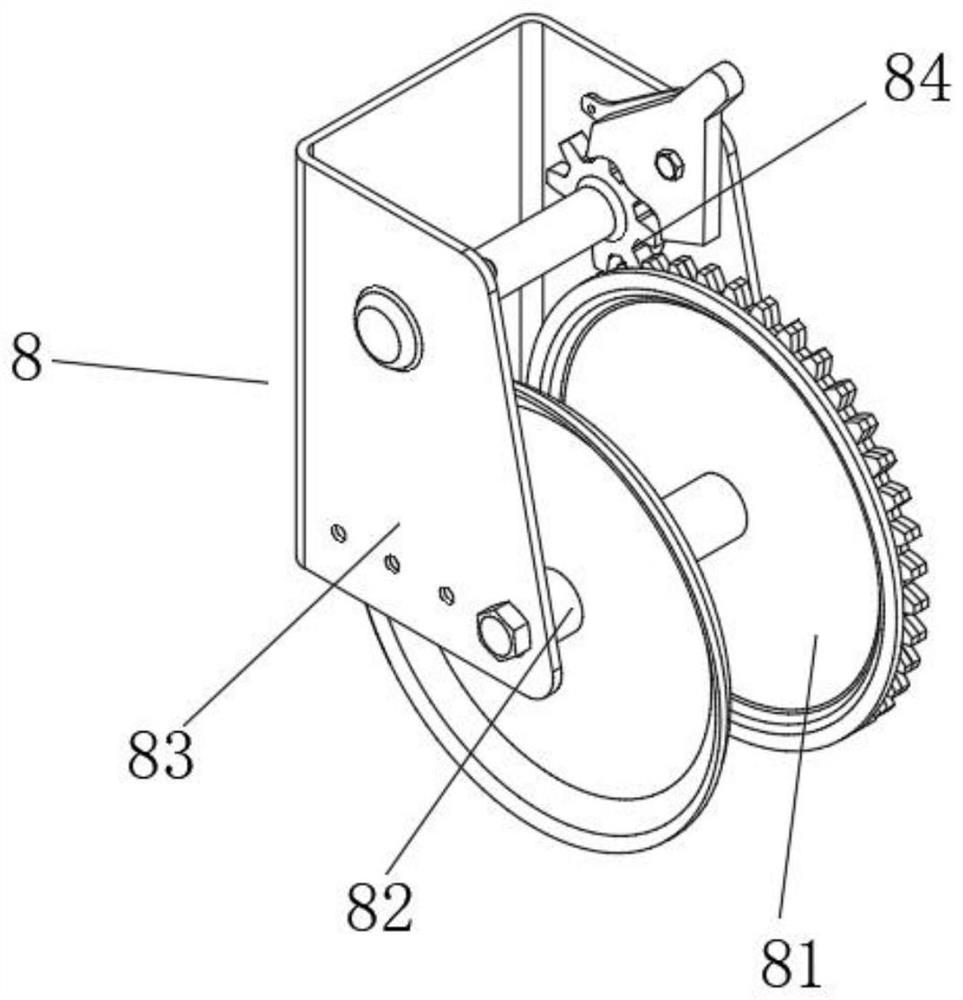

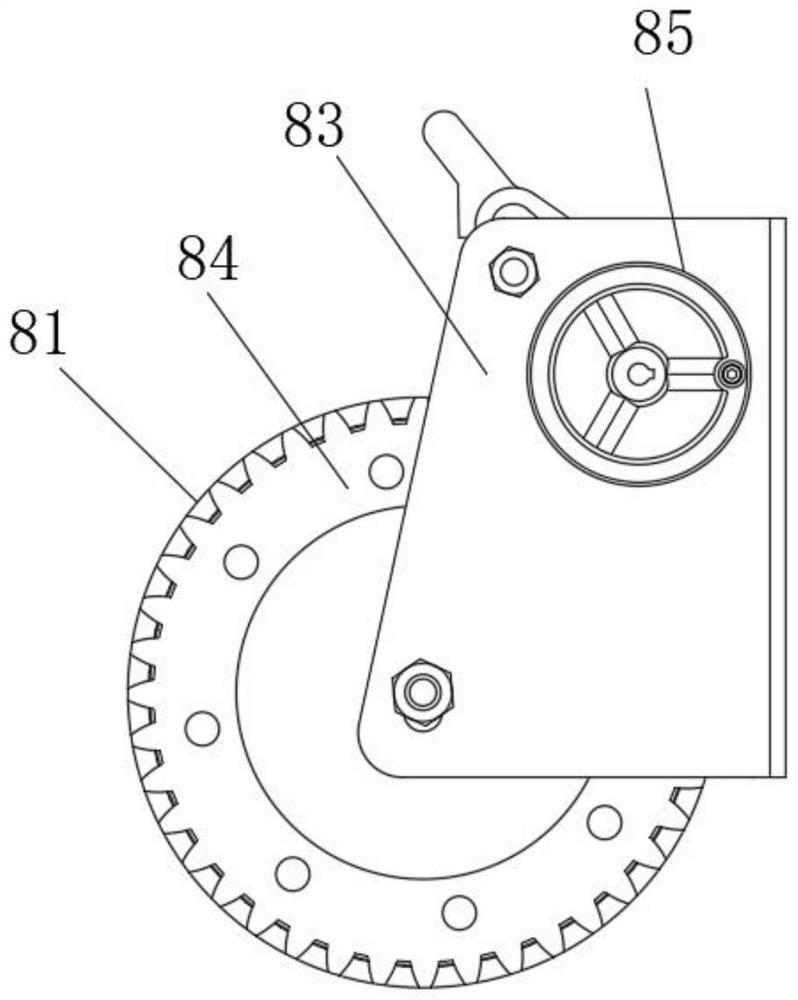

[0038] The present invention provides a rope winding device for hoisting equipment for power cables through improvement. The auxiliary winding device 8 is installed on the rear upper side of the reel 2, so that the cable can be wound on the reel 2 after passing through the auxiliary winding device 8. , to realize the adjustment of tightness, the two ends of the auxiliary drum 81 are fixed to the front end of the rotating fixed frame 83 through the two ends of the rotating shaft 82, so that the auxiliary rotating drum 81 can rotate inside the rotating fixed frame 83 through the rotating shaft 82, and the limit Clamping plate 844 is provided with and is used for manually pushing lug, can make limit clamping plate 844 rotate by pushing lug, pressure pushing device 106 both sides are respectively provided with guide rod, and this guide rod connects and fixes push plate 103, uses Stability is maintained when the upper tube support 101 and the lower tube support 102 are telescopicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com