Discharging nozzle automatic switching filling machine capable of simultaneously conducting filling and cleaning

A technology of automatic switching and feeding nozzle, which is used in the cleaning of filling devices, bottling machines, packaging, etc., which can solve the problem of shortening the life of connecting parts and sealing parts, the inability of filling machines to perform filling operations, and reducing the effective operation rate of equipment, etc. problems, to achieve the effect of ensuring stability, driving stability, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

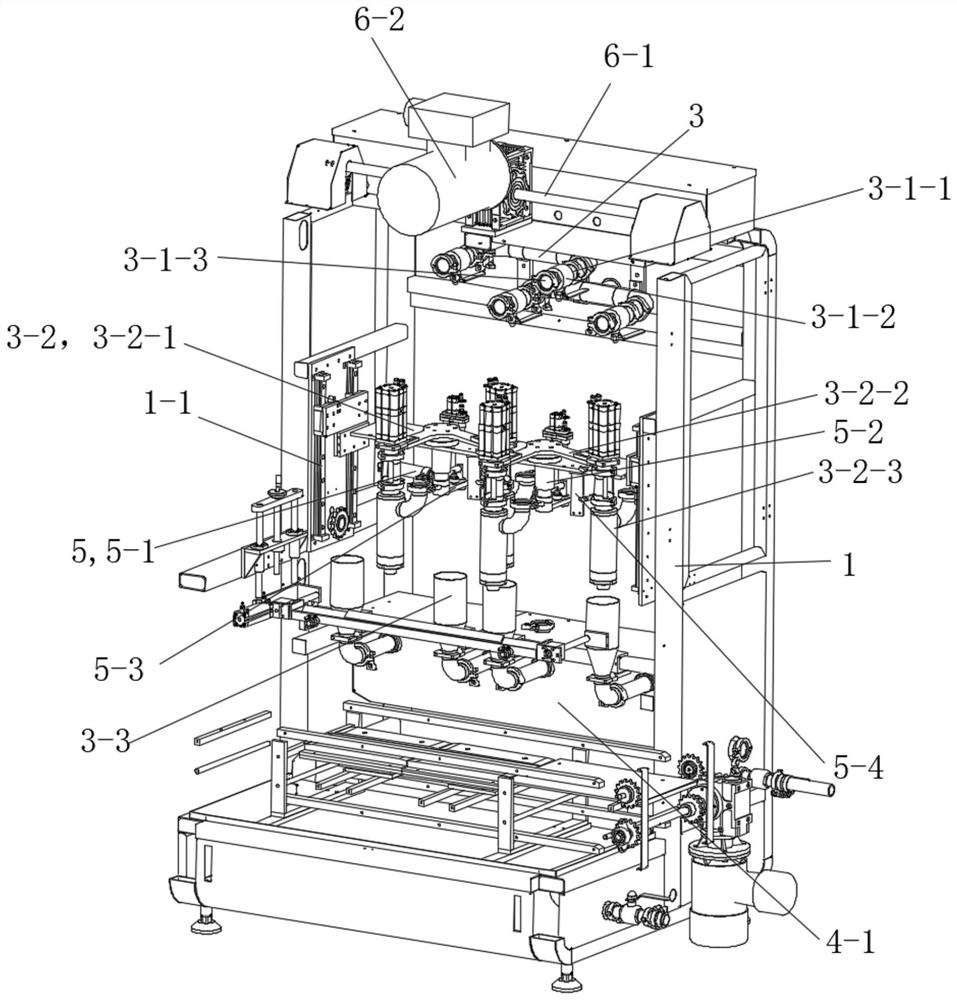

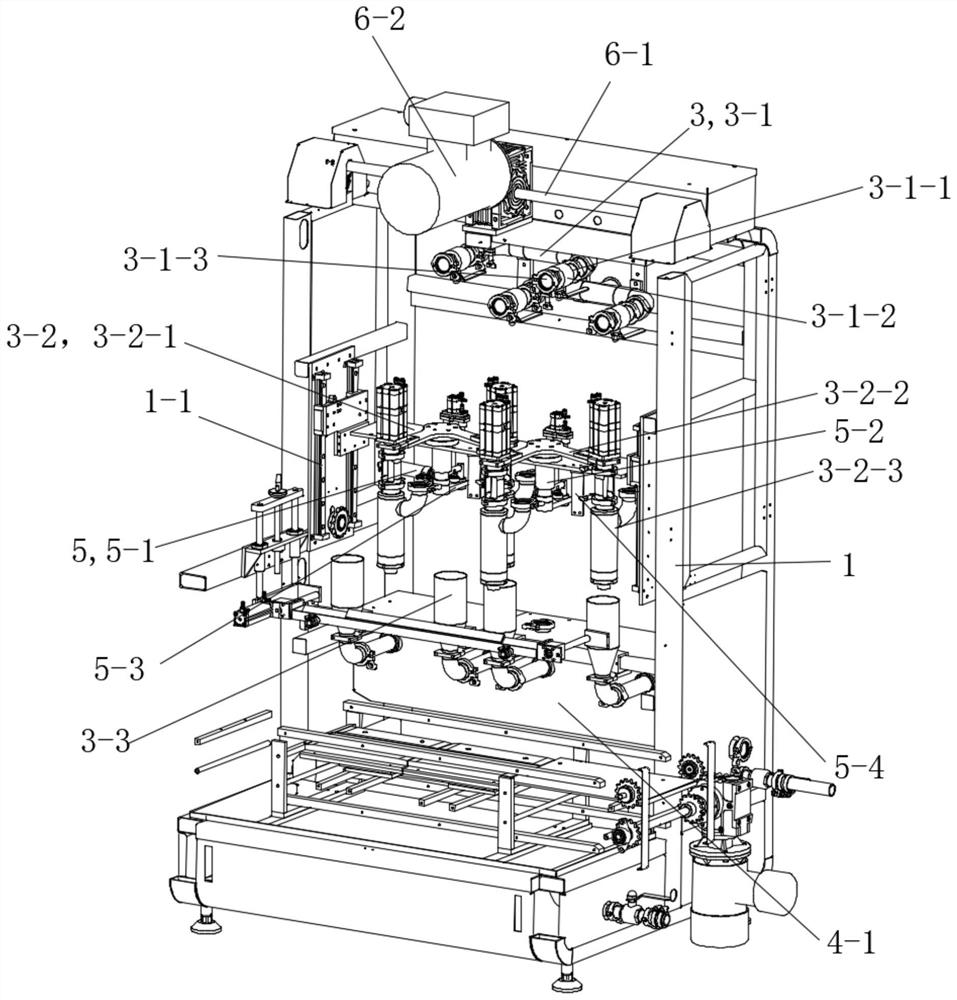

[0037] See Figure 1 to Figure 7 , the present embodiment can be filled and cleaned at the same time the feeding nozzle automatic switching filling machine, including the frame 1 and the filling conveyor line 2 located on the frame 1, the filling mechanism 3 and the cleaning mechanism 4.

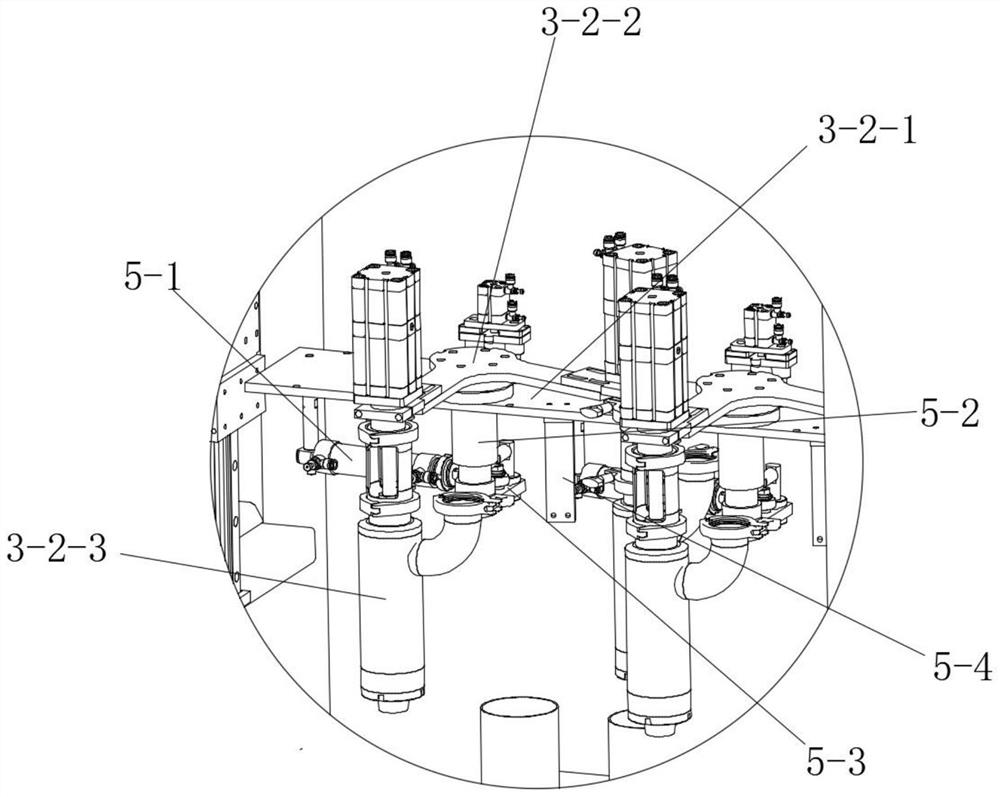

[0038] The cleaning mechanism 4 includes a liquid inlet and a collection box 4-1. Both the filling mechanism 3 and the liquid inlet are provided with two. The filling mechanism 3 includes a feeding part 3-1 and a feeding part 3-2 communicating with the feeding part 3-1. The two liquid inlets communicate with the feeding parts 3 - 1 of the two filling mechanisms 3 respectively. The blanking parts 3-2 of the two filling mechanisms 3 are all rotatably arranged on the frame 1, and each blanking part 3-2 is driven to run by a blanking part driving mechanism 5. The collecting box 4-1 is provided with a cleaning liquid connection pipe 3-3 corresponding to the feeding parts 3-2 of the two filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com