A Yunbo Torque Sensor

A torque sensor, Yunbo's technology, applied in the direction of torque measurement, instruments, measuring devices, etc., can solve the problems of difficult maintenance of the service life of the sensor, low power conversion efficiency, electromagnetic radiation of the magnetic circuit, etc., and achieve a novel and unique design concept Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the embodiments shown in the accompanying drawings.

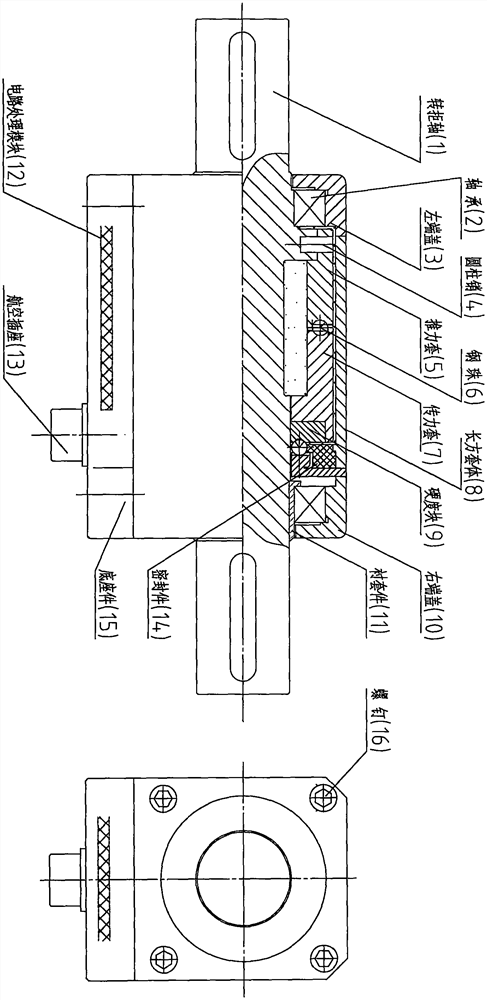

[0021] figure 1 A schematic diagram of the overall structure provided by this embodiment, the Yunbo torque sensor is composed of four parts: a sensor housing assembly, a torque shaft assembly, a deformable body force measuring assembly, and a base assembly;

[0022] in figure 1 The sensor housing assembly realizes the bearing of the torque rotating shaft and the base;

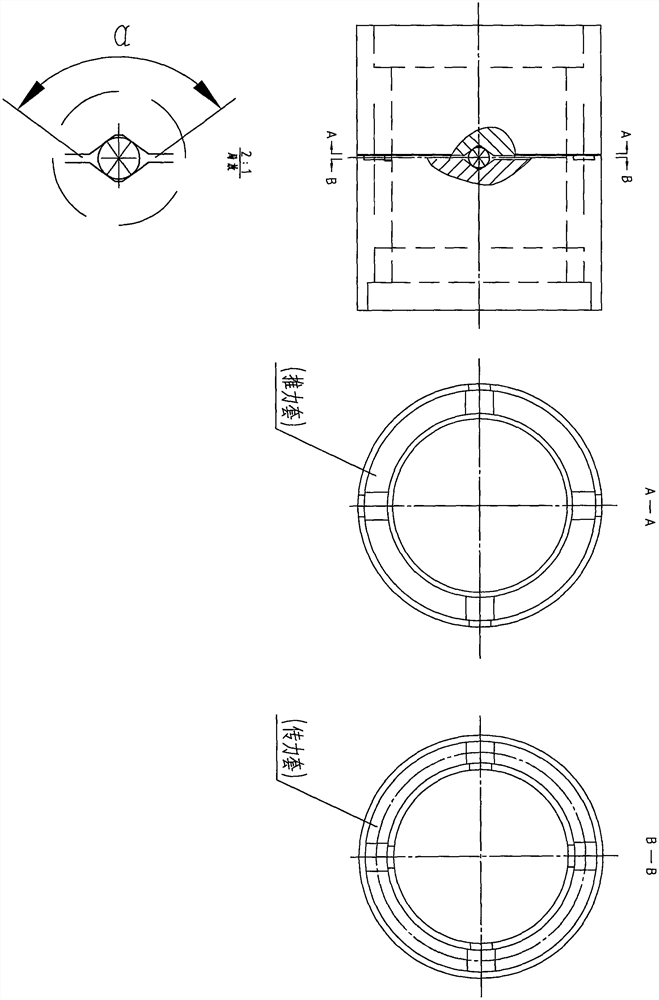

[0023] in figure 1 The torque shaft assembly realizes the transformation of the relationship between the axial displacement of the force transmission sleeve ΔL and the function of the torsion angle ψ;

[0024] in figure 1 A circuit processing module (12) is built in the base assembly to realize the logic processing of the power supply of the strain gauge bridge and the torque signal and output through the aviation socket (13) interface.

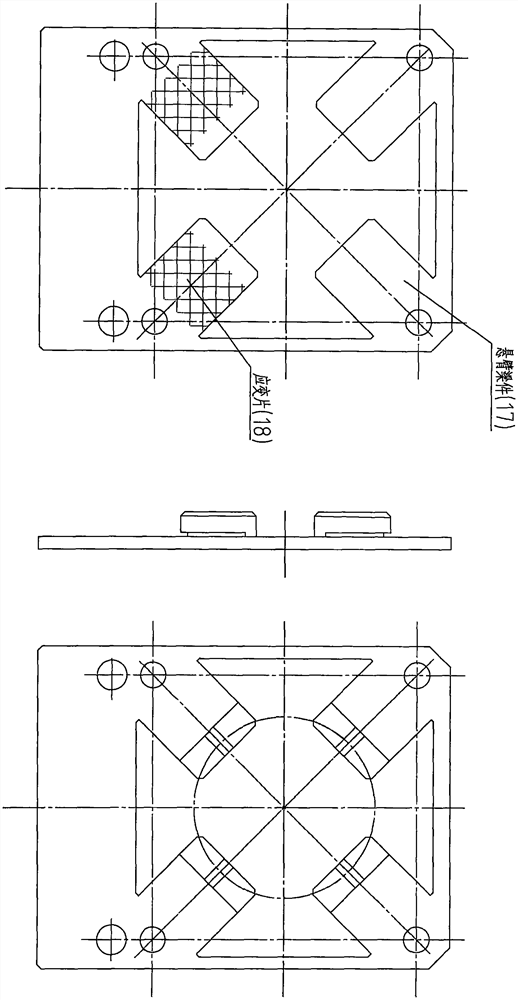

[0025] figure 2 It is a schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com