Methods for improving cell viability in production bioreactor

A bioreactor, cell technology, applied in the fields of biotechnology and cell biology, can solve the problems of cell shear sensitivity and increased cell death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

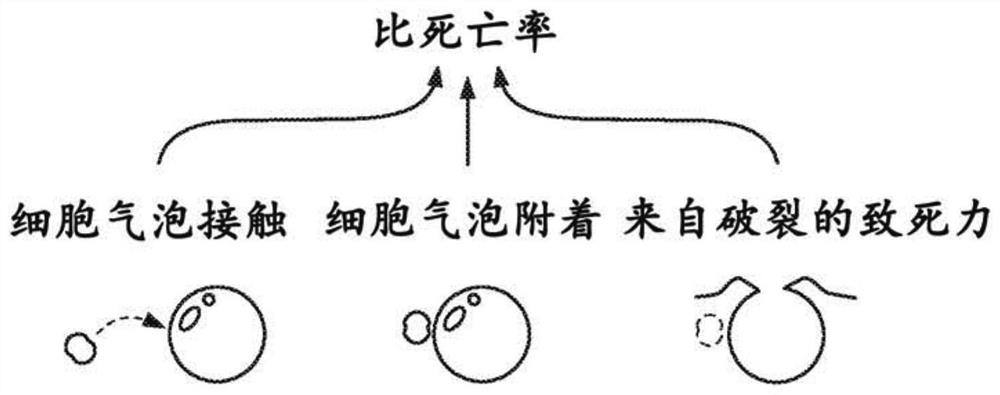

Problems solved by technology

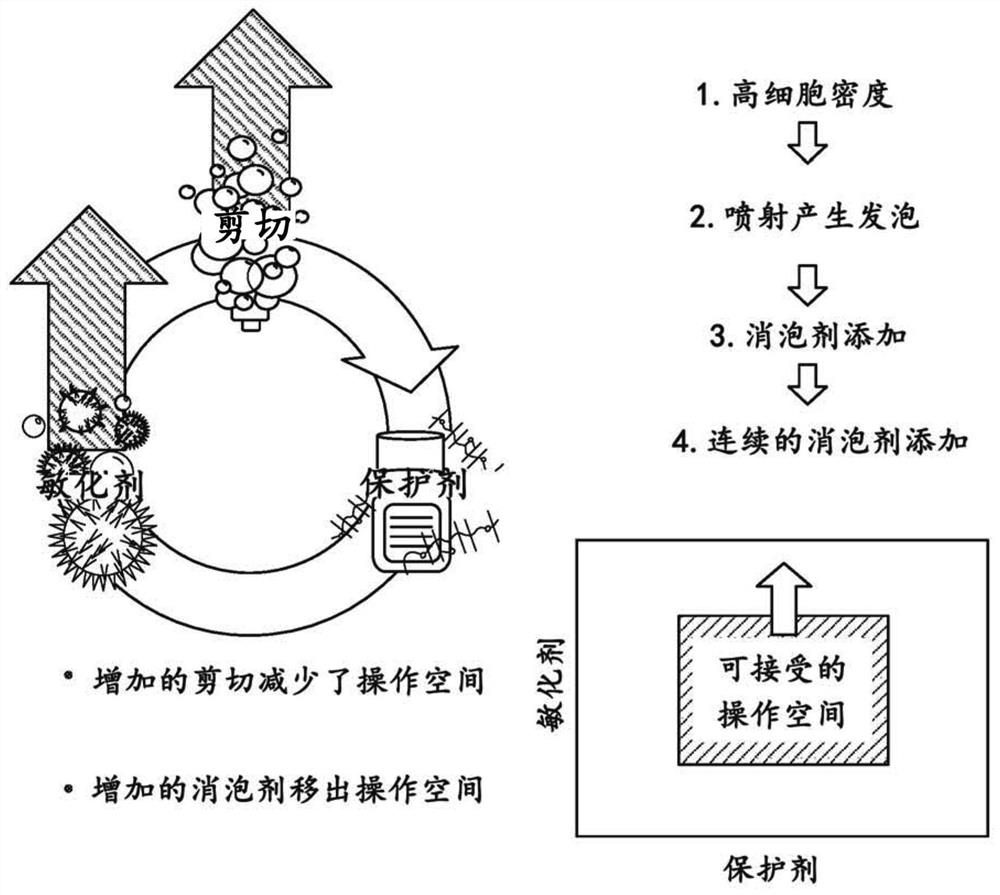

Method used

Image

Examples

Embodiment 1

[0273] Example 1: Combination of full factorial screening of test culture vessels with an endocentric composite design

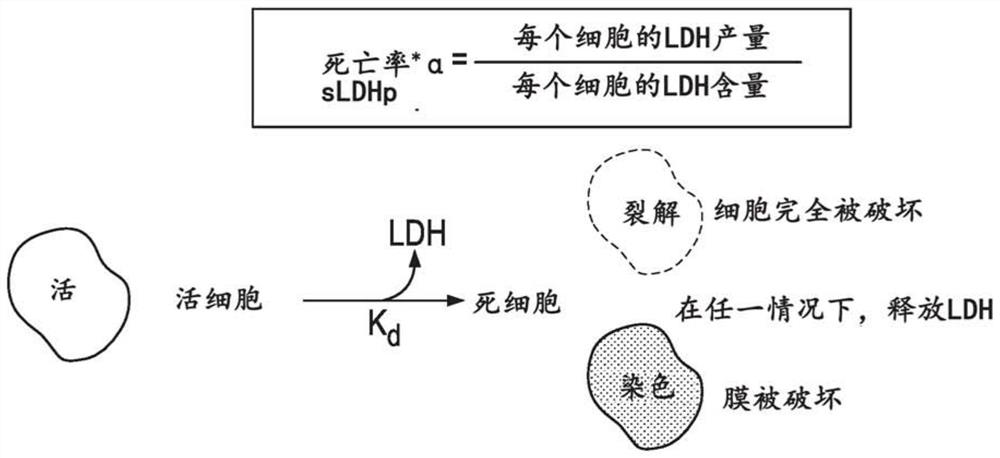

[0274] Select rotary agitation (RPM 3 ), sensitizer concentration and protectant concentration as parameters. A full factorial design combined with an endocentral composite design was used to determine a set of test conditions ( Figure 7). Specific LDH production values were measured for each test condition. The results are used to provide estimated contours for the selected parameters. Identify areas of poor performance and operational failures ( Figure 9 ).

Embodiment 2

[0275] Example 2: Prediction of Specific LDH Production Values at Bench Scale

[0276] A proof-of-concept experiment was performed at bench scale to determine the accuracy of the prediction method as described herein.

[0277] The protectant concentration in bench scale was set at three different levels. For each level, two benchtop culture bioreactors were tested. Measure the peak value of specific LDH production due to the perfusion process and compare it to the predicted value.

[0278] Actual observations from bench-scale experiments matched those predicted very well (P2 =0.84)( Figure 13A and Figure 13C ). It turns out that the method as described here can be successfully used to predict the impact of multiple parameters at higher scales.

[0279] Experiments were conducted to maintain the defoamer concentration in the range of 30-40 ppm defoamer addition per day. Pluronic concentration was adjusted from 1.8g / L (dotted line), 2.8g / L (solid line, filled circle), ...

Embodiment 3

[0281] Embodiment 3: Predict the specific LDH output value under the production scale

[0282] Experiments were performed at production scale to determine the accuracy of the models as described herein.

[0283] Three 50L production bioreactors and two 100L production bioreactors were tested. Poloxamer-188 (Pluronic) concentrations ranging from 1.8 g / L to 5.8 g / L were experimentally tested.

[0284] The actual observed values for specific LDH production matched these predicted values very well (P2 =0.84)( Figure 15A and Figure 15B ). The results demonstrate that the method as described herein can be successfully used to predict the impact of selected parameters at production scale (production bioreactor scale).

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com