Wet process desulphurization and dust removal device and wet process desulphurization and dust removal method using same

A technology of wet desulfurization and dust removal equipment, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as chimney trailing, and achieve the effects of eliminating potential safety hazards, eliminating smog, and making full use of land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

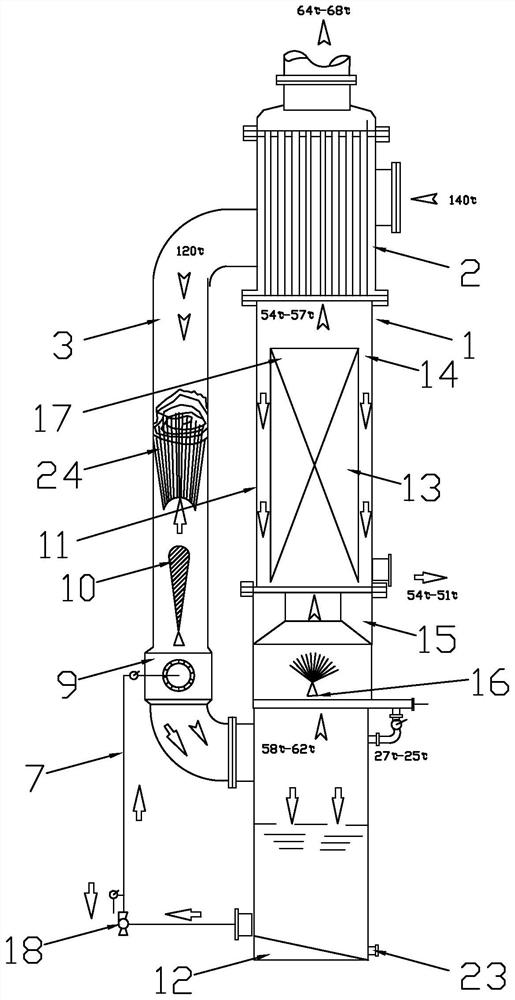

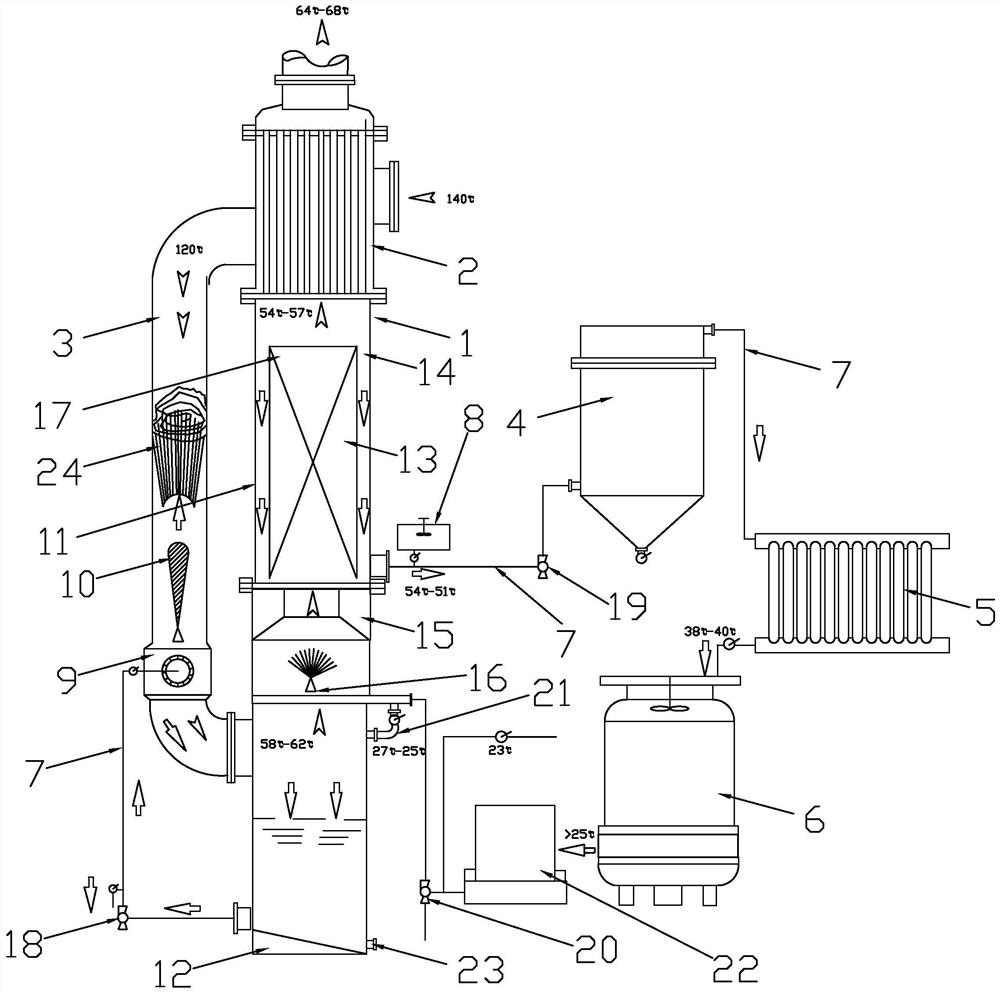

[0031] see Figure 1-Figure 2 Shown: Wet desulfurization and dust removal device, including comprehensive tower 1, heat exchanger 2 installed on the top of comprehensive tower 1, reverse nozzle 3 connected to heat exchanger 2 and comprehensive tower 1 and arranged in communication, and comprehensive tower 1 The fast solid-liquid separator 4 used in conjunction with the fast solid-liquid separator 4, the air-cooled pipe 5 used in conjunction with the air-cooled pipe 5, the cooling tower 6 used in conjunction with the air-cooled pipe 5, and the cooling tower 6 delivers the liquid medium to the integrated tower 1 , between the countercurrent pipe 3 and the comprehensive tower 1, between the comprehensive tower 1 and the fast solid-liquid separator 4, between the fast solid-liquid separator 4 and the air-cooled exhaust pipe 5, and between the air-cooled exhaust pipe 5 and the cooling tower 6 , between the cooling tower 6 and the comprehensive tower 1, an infusion pipe 7 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com