Millstone device for processing flour and application method of millstone device

A flour and stone grinding technology, applied in chemical instruments and methods, applications, grain processing and other directions, can solve the problems of difficulty in ensuring flour accuracy, difficult flour filtration and screening, and large nutritional damage of flour, so as to improve grinding efficiency and improve grinding accuracy. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

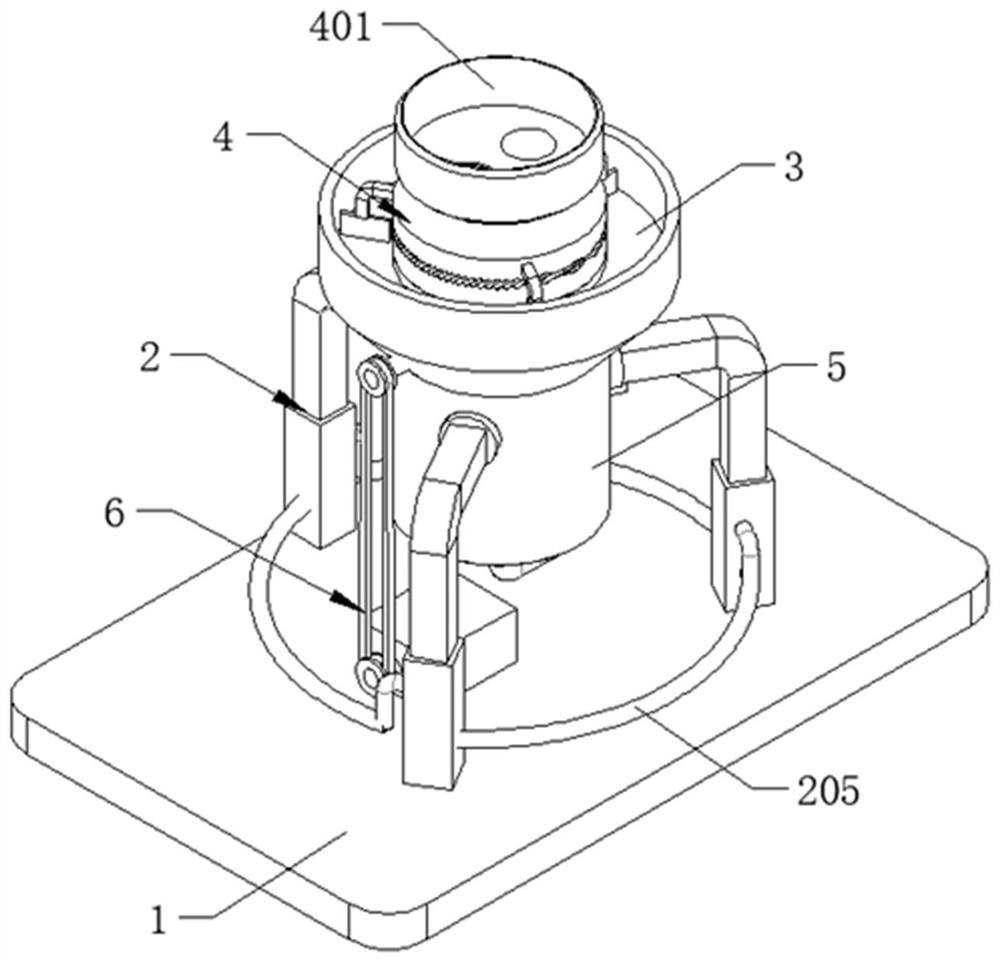

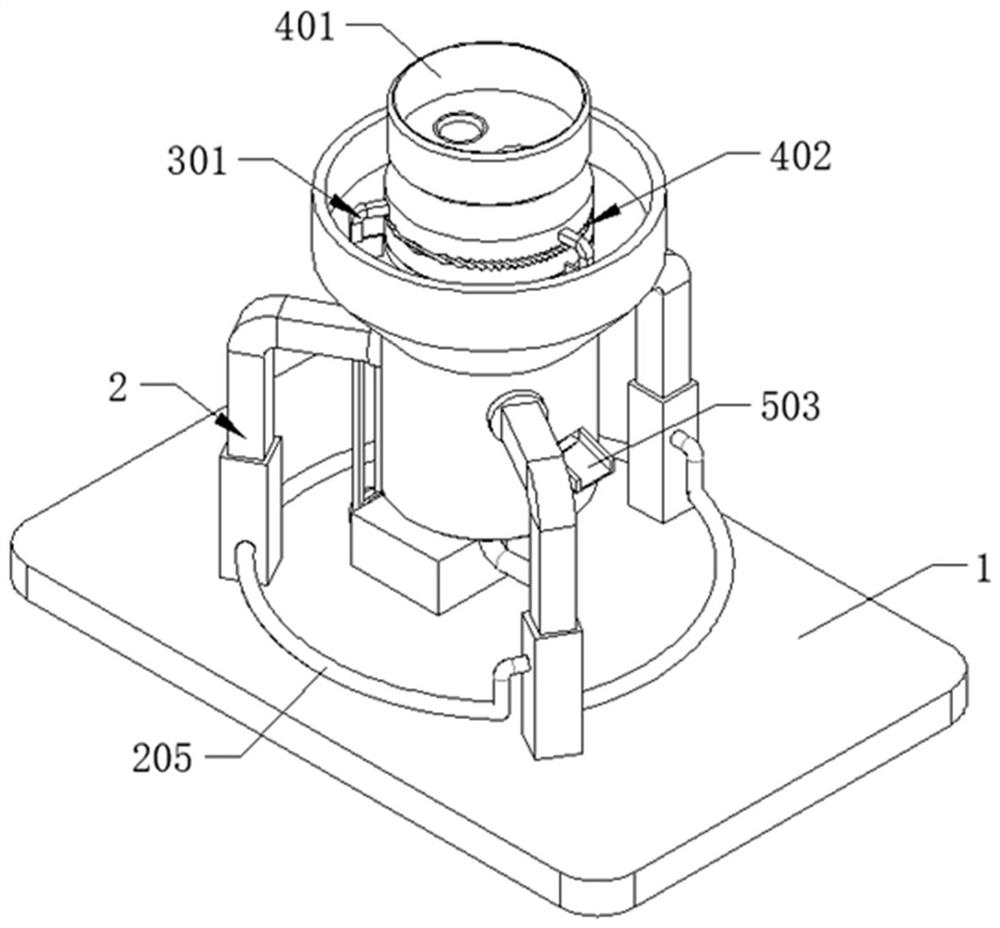

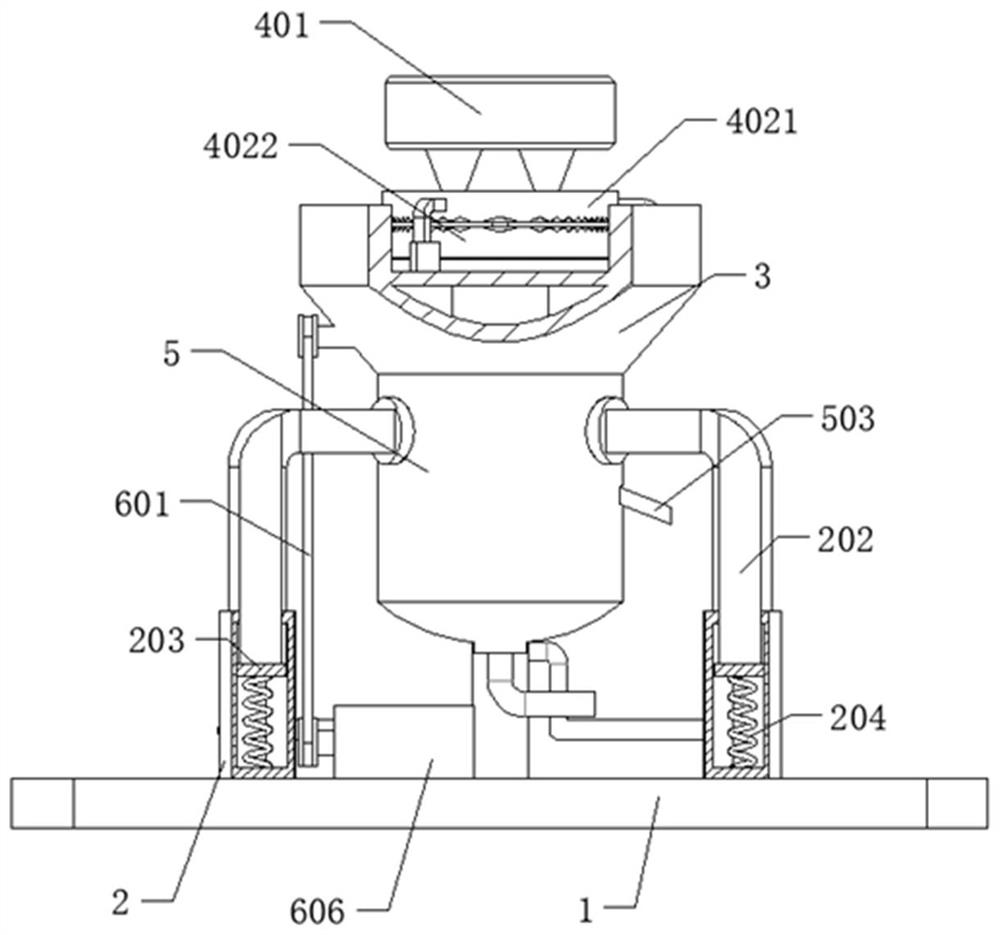

Embodiment 1

[0038] refer to Figure 1-7 , a stone milling device for processing flour, comprising a bottom plate 1, a supporting leg 2 and a grinding disc assembly 4, the supporting leg 2 is connected to the top wall of the bottom plate 1, the grinding disc assembly 4 is connected to the end of the supporting leg 2 away from the bottom plate 1, and the grinding disc The assembly 4 includes a trough 401, a grinding mechanism 402, an external disc 3 and a storage tube 5, the storage tube 5 is connected to the top of the bottom plate 1 through the support legs 2, and the external disc 3 is connected to the top wall of the storage tube 5, and The external disk 3 communicates with the storage barrel 5, and the grinding mechanism 402 is connected to the inside of the external disk 3, and is connected in rotation with the external disk 3. A scraper assembly 301 is also arranged between the grinding mechanism 402 and the external disk 3, and the bottom plate 1. A power mechanism 6 is connected to...

Embodiment 2

[0044] refer to Figure 4-7 , a stone milling device for processing flour, which is basically the same as that in Embodiment 1, furthermore, the sieve assembly includes a sieve plate 501, which is arranged obliquely on the inner wall of the storage cylinder 5, and the inner wall of the storage cylinder 5 A chute 502 is dug on the top, and the sieve plate 501 is slidably connected in the chute 502 .

[0045] The outer wall of the storage barrel 5 is dug with a first discharge opening, the outer wall of the storage barrel 5 is connected with a material guide plate 503 matching the first discharge opening, and the bottom wall of the storage barrel 5 is also dug with a second discharge opening. mouth.

[0046] The reciprocating assembly includes a first rotating disk 7, a second rotating disk 701 and a support rod 702. The first rotating disk 7, the second rotating disk 701 and the supporting rod 702 are all connected to the outer wall of the third rotating shaft 605. The first r...

Embodiment 3

[0049] refer to Figure 1-3 , a stone milling device for processing flour, which is basically the same as in Example 1, furthermore, the supporting leg 2 includes an outer rod 201, an inner rod 202, a piston 203 and an elastic member 204, and the outer rod 201 is connected to the bottom plate 1 On the top wall, the piston 203 is connected to the inner wall of the outer rod 201, the inner rod 202 is connected to the top wall of the piston 203, and the inner rod 202 and the outer rod 201 are slidably connected, and the end of the inner rod 202 away from the outer rod 201 is connected to the stocker. On the outer wall of the cylinder 5 , the elastic member 204 is connected between the bottom wall of the piston 203 and the inner wall bottom wall of the outer rod 201 .

[0050] Connecting pipes 205 are connected between adjacent supporting legs 2, and the connecting pipes 205 are all connected to the outer wall of the outer rod 201, and one end of the connecting pipe 205 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com