Badminton racket double-head automatic drilling machine and drilling method thereof

A badminton racket and drilling machine technology, used in drilling/drilling equipment, boring/drilling, boring machine/drilling machine components, etc. Flying around and other problems, to avoid the offset of the position of the mold, save costs, and improve the drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0038] Example.

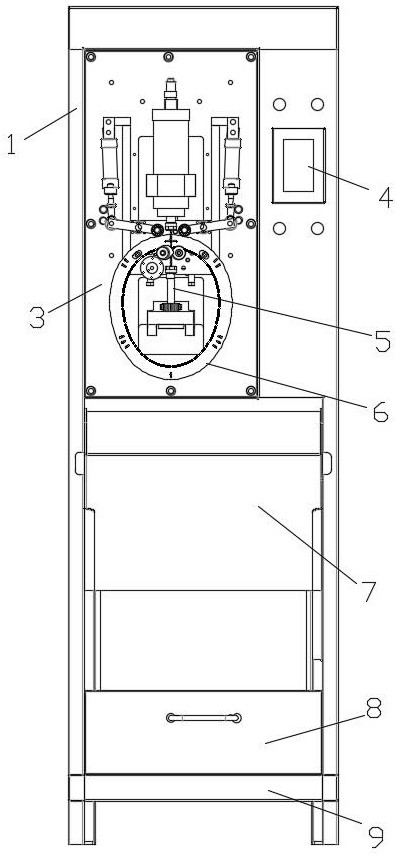

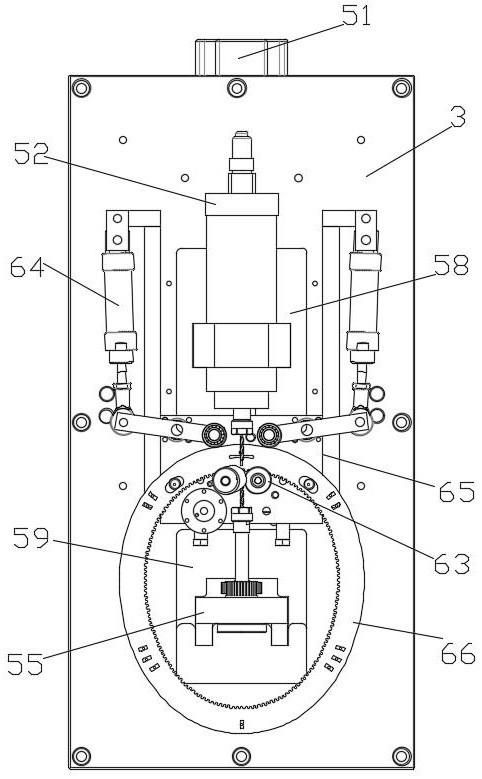

[0039] see Figure 1 to Figure 8, the double-headed automatic drilling machine for badminton racket in the present embodiment comprises a cabinet 1, a display screen 4, a chip guide 7, a chip storage drawer 8 and a drilling device; the display screen 4, the chip guide 7 and the chip storage drawer 8 all Installed on the chassis 1; the drilling device includes a main panel 3, a drilling mechanism 5 and a roller pressing mechanism 6; the main panel 3 is installed on the chassis 1; the drilling mechanism 5 and the roller pressing mechanism 6 are installed on the main panel 3 On the cabinet 1, there is also a cabinet door 2 that is easy to open for inspection and maintenance of the drilling device; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com